Overhead crane or bridge crane safety prevents incidents and can save time and money. The right personnel and equipment will ensure that your warehouse works with all the guarantees.

Today we are reviewing some overhead crane safety tips to protect your workers.

What is an overhead crane?

Please! If you are an expert in material handling and lifting equipment, please skip this part. Indeed, you are more interested in the safety tips about cranes.

An overhead crane is a piece of gear that permits you to lift and move weighty materials starting with one area and then onto the next in an exact way. There is no “one size fits all” way to characterize a crane. Every machine is thoroughly planned and designed for a particular reason or application to suit a project’s necessities.

These are a fast way to move and transport different loads in many industries. It consists of parallel runways with a traveling bridge. The hoist travels along the bridge and helps save time and money for handlers and companies.

There are a lot of types of overhead cranes: gantry cranes (support large equipment), jib cranes (building support), workstation cranes, overhead bridge cranes, monorail cranes or bottom % top running cranes.

Without these cranes, we couldn’t achieve operations like that.

Functions of an overhead crane operator

An overhead crane operator operates traveling or stationary overhead cranes to lift, move, and position loads (like hardware, heavy items, machinery, and bulk materials) utilizing hoisting connections, like hooks, slings, electromagnets, etc. The operator observes load hookup, determining the load’s safety.

Handling a crane is quite an important job. To save time and money, the overhead crane operator must be cautious in its use.

Yes, also an overhead crane is perfect to check your space savings because it allows you to put everything in its correct place. Your warehouse manager could use it too.

Add these tips to your safety checklist. This way, you won’t forget to ensure that everything works fine.

Overhead crane safety rules

1. Maintenance is essential: make a crane inspection every time

Make sure that your hoist works fine. It’s mandatory before using it, but if you are not currently using it, check it too. It will save you time and will make everyone safer.

Periodic inspections of the hoist can identify potential issues before they escalate into significant problems, ultimately saving time and resources in the long run.

2. Check that the crane hook has no obstacles

It may seem obvious, but your load will go through the air above your head. No obstacle must come between it and the end of the runway.

Before initiating any movement, a thorough check of the crane’s path must be conducted to confirm that it is free of any obstructions that could interact with the load.

3. The crane operator and the rest of the employees must be aware

If you are going to use the overhead crane, make sure everybody in the workplace knows about it. Remember, the load moves above everyone’s head, so sometimes you don’t see it unless you look up.

Training your employees who are on site, warehouse or other points where you have cranes is 100% necessary. Expert training is not necessary, but rather one focused on security and risk.

4. Quick overhead crane safety tips while using it

- Do not get distracted by anything

- Do not swing the load

- Do not move your load with coworkers around the area

- Do not move any loads over people

5. Remember your overhead crane limits

The weight limit in the handling systems is there for safety reasons. So do not push the limits and move the load limit that your overhead crane has.

If you have any doubts about it, talk with the distributor about technical specifications.

6. Test your lifting equipment

At Crosby Airpes, we know how important it is to check out your equipment. Testing is a safe way to push your lifting equipment and find out how it performs in any situation. Remember to test your overhead crane for your safety.

Want to know more? Keep reading: Airpes designs the best equipment for your overhead cranes

Complement your work with the best overhead crane equipment

At Crosby Airpes, we take care of designing and manufacturing the best equipment for your bridge crane. Improve the lifting capacity of your machinery. Discover our outstanding products:

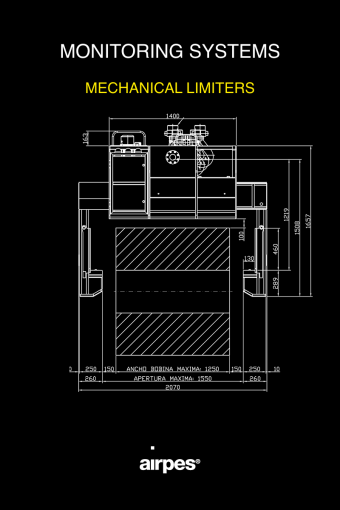

Load limiters

We have our Eagle Electronic Limiter, one of the latest electronic limiters that will be the brain of your industrial crane. The limiters are responsible for monitoring and protecting the bridges of your overhead crane.

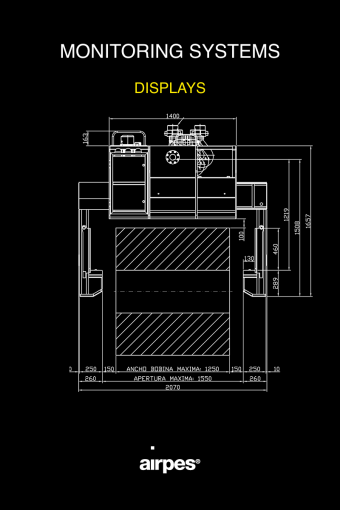

Display

With our display products, you can see the details of the charge of the overhead bridge crane quickly and easily. We also have panels, repeaters, loading screens, and indicators.

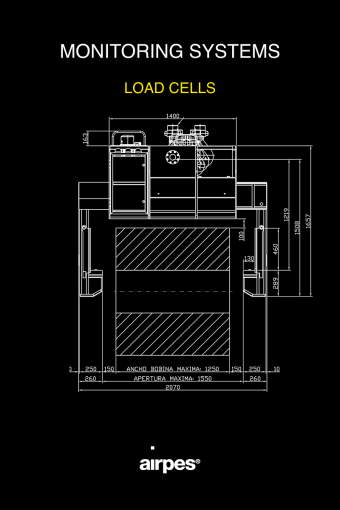

Load cells

Another way to capture weight data from crane bridges is load cells. They inform us about the load’s weight in different conditions (you can check load capacities’ machinery easily).

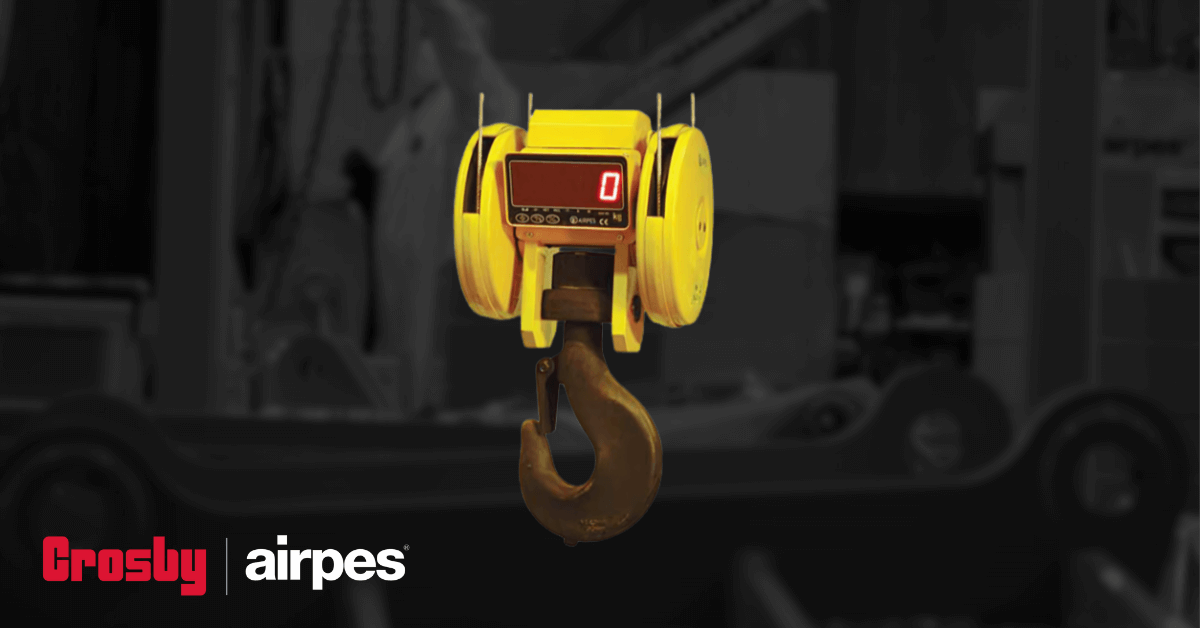

Hooks

Hooks are placed hanging from the bridge crane. The hooks are responsible for controlling the entry and exit of products and the stock or storage.

Radiocontrol equipment

We trust Autec, the best radio control product to control your overhead crane.

You may be interested in: 10 safety precautions when using lifting equipment

Crosby Airpes offers you solutions adapted to your overhead crane

We have more than 20 years of experience designing and manufacturing on-demand equipment for all types of overhead cranes.