Cranes are equipment designed to handle heavy loads, lifting and lowering materials. Their automation improves the safety of the installations, offering precision in the movement of the load and efficient performance.

In this post, we are going to talk about automatic cranes. They stand out for their versatility, which allows the operator freedom of configuration, covering complex and repetitive operations thanks to the perfect combination of hardware and software.

Why choose an automatic crane?

While it is true that cranes are one of the first devices invented in the world, their evolution to today’s cranes has been abysmal. Almost all industries have historically used manual cranes to handle heavy parts used in different processes, such as storage, assembly, or moving.

This situation has changed over time. Today, much heavier loads need to be moved with precision and safety. Hence, automatic cranes appear as a technological solution that allows different operations, reducing waiting time and saving space.

Regardless of the sector in which your company operates, the level of competition is likely to be high, and labor costs will increase, so having an automatic crane will make it possible to:

- Handle heavy loads efficiently

- Reduce operating costs by requiring less personnel and streamlining operations

- Increase productivity by increasing the efficiency and effectiveness of the work performed

- Improve safety at work by incorporating systems that automate your cranes, especially when working in hazardous areas or with dangerous materials

- Reduce damage when handling objects

- Optimize inventory management

- Configure the movements to be performed

What types of automatic cranes are available on the market?

There are different types of automatic cranes, from overhead cranes, gantry cranes, telescopic cranes, jib cranes, and industrial cranes. The choice of crane will always depend on the work you want to do.

Depending on your choice, you can hoist loads, make horizontal movements, and balance loads. Remember not to move a load whose weight exceeds the crane’s capacity, as this will affect the crane’s balance.

The people in charge of calculating the weight of the load and the lifting capacity of the cranes are called crane operators or operating engineers, essential personnel when carrying out any work with such delicate equipment.

You may be interested in: The secrets of mega cranes that no one has told you

What is the applicability of automatic cranes?

The scope of action is diverse. Some applications are:

- Handling of paper rolls, steel coils, containers, etc.

- Shipbuilding

- Heavy construction

- Mechanical workshops

- Food production

- For lifting all kinds of loads

What do we offer at Crosby Airpes to automate your cranes?

We can improve and automate your cranes, no matter what type of crane it is. We will install the systems you need to automate your crane. Among the most innovative are the weighing system and remotely controlled cranes, which we will explain below.

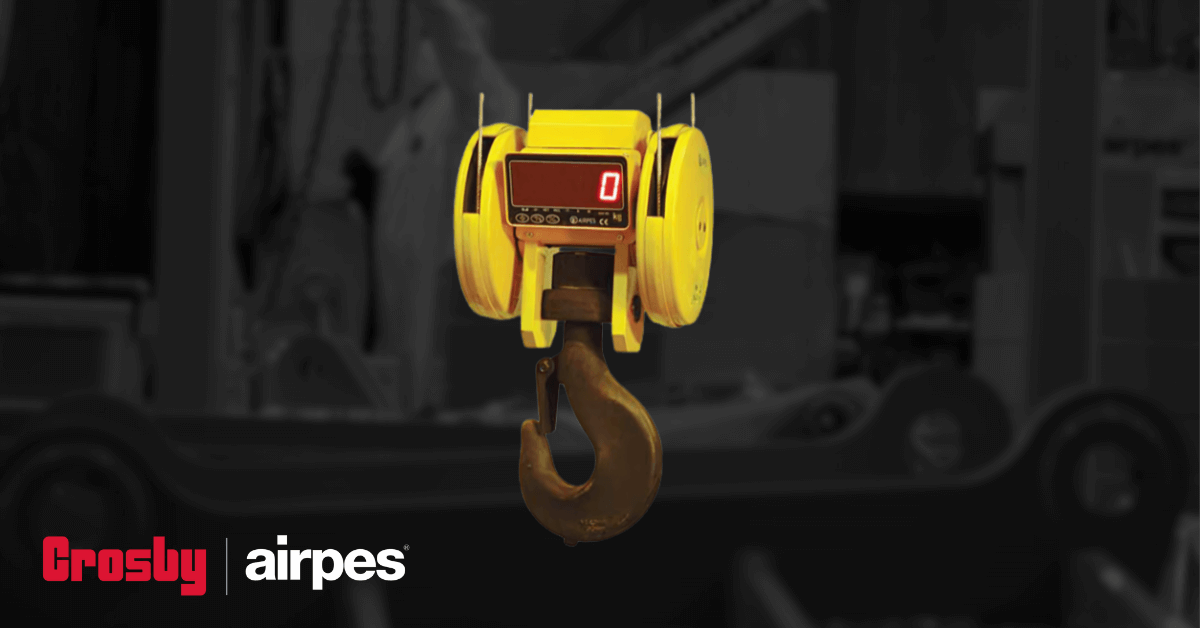

Weighing systems

This system will let the operator know in real time if the weight loaded by the crane is the right one. At Crosby Airpes, we have different components that adapt to any crane. We have extensive experience in the design and manufacture of weighing systems, which follow the quality and safety standards indicated by the European Union.

- Digital crane scales allow you to weigh your load on time

- Weighing hooks are an ideal complement to checking goods in and out of the warehouse

- Weighing blocks allow you to lift and transport a load simultaneously as it is weighed. For this, there is no need to install another scale. With the LED or LCD (backlit panel), you will have precise weight, managing to control almost all the functions remotely. The ATP – 100 models are available for weighing from 2,000 to 250,000 kg.

- The weighing pallet truck performs the same functions as the weighing blocks. It moves the load and weighs it at the same time. The advantage is that you can save time by shortening some processes, such as inspection. In addition, your weighing will be reliable, and if there is an error in the quantities, it will detect it immediately.

We also have other complements that will help you in your weighing activities, such as:

- Electronic limiters and mechanical limiters will be the brain of your crane

- Load cells for tanks that will help you to capture the weighing data

- Displays that will allow you to view load data quickly and easily

Remotely controlled cranes

Within the movement of loads, one of the technological advances that have had a positive impact has been the use of remote control in cranes, which is different from the usual procedure of cable systems.

The technology used for remotely controlled cranes can be infrared light or radiofrequency. The latter is the most widely used due to the range of action it covers and its operability despite environmental conditions or objects in its perimeter. Therefore, infrared light is less popular due to the high probability of deviation of the light path, either by airborne particles or entities that have a specific size obstructing it.

Implementing this system in your cranes will reduce accidents with the crane or load, increase productivity and modernize processes, making you more competitive in the market.

Crosby Airpes helps you automatize your crane

An automatic crane will be your solution when working at height and moving heavy loads safely, allowing you to facilitate complex and repetitive operations. Systematize your industrial processes, reduce costs and provide safety to your employees by automating your loader cranes.