In a job that includes cranes and lifting projects, crane safety and efficient and safe execution is expected. Remember: safety of both workers and equipment is essential, and also ensuring proper ground conditions is crucial for avoiding accidents and maintaining stability .For this reason, today we share with you 10 tips to follow so you lifting and weighing operations are as safe as possible.

Ensure crane safety with these tips

What are the most important things to take into account for a correct crane safety operations?

Operators have to be qualified

It’s not only about having experience and knowledge, but also little details like as periodically reviewing manuals and rules of the handling the right equipment to use. Training is very important and must be continuous. Crane operators should not only rely on electronic limiters ( or mechanical limiters) but also ensure they know how to handle unexpected situations.

Find the best enviroment for a safe crane operation

Something as simple as turning your phone off when you’re in the cab is essential to avoid distractions that could compromise your lifting job.The site should be free from potential hazards, and the operator should inspect it thoroughly.

Pre-operational inspection of the handling equipment

¿Did you know that 74% of crane accidents and tip overs occur during routine operations? It is very important to inspect the state of your handling and weighing equipment before starting to maneuver. Checks like pre-start inspections and confirming the load radius are essential.

Do a checklist with everything you need to ensure the crane’s safety

A very good way to keep track of everything is to make a list of actions to check before starting to use the equipment. You won’t start until all is checked. This should include verifying the load charts and making certain that you’ve made a solid safety assessment.

Make sure you have clear visibility of the whole crane’s working area

You can have the best lifting and weighing equipment, but don’t forget about the environment you’re working on. Pay special attention to the ground conditions to ensure stability and safety during operations.Make sure you have full visibility, that there are no dead spots and that you can fully control the situation at all times.

Ensure loads meet equipment capacities

Loads to be moved or elevated must be well secured and follow all safety measures regarding shape and weight. Crane operators should still know how to rig the load cells correctly. According to a study by Arnold & Itkin in 2015, 80% of accidents involving loads in the United States are related to an excess of recommended weight.

Make sure only one person can control the lift and machinery

When a worker is in charge of lifting the load, he must be solely responsible for it, avoiding confusion over responsibilities and tasks performed.

Related post: Safety during electromagnets operation

NEVER stand under a load for a safe crane operation

One of the most basic essential overhead crane lifting safety tips in any workplace where you carry out handling and lifting projects: never stay under a suspended load.

Although the risks may seem obvious, it is still common for workers to place themselves under loads when operating lifting devices. You mustn’t do this because if something goes wrong, you are at serious risk of being hit by something you are lifting.

It is essential always to maintain a safe distance from the load you are moving to ensure that you are not at risk and can handle the situation safely in an error, equipment failure, or other problem.

Do not leave the load suspended in air for more time than needed

In the same line, neither should the load be left suspended for a long period of time. Once you start moving it, it is better to finish it to avoid any kind of accident. The person responsible has to be constantly aware of it: Many crane accidents occur due to improper handling or delays during the lift.

Proceed with the lifting operation slowly and properly

Avoiding rush and staying calm throughout the process will make the end as comfortable and safe as possible. Do not accelerate or brake abruptly to prevent the load from swaying. Proper communication and hand signals are also critical for the job.

Safety comes first when working with heavy machinery.

Related posts:

- Ensure a safe handling and weighing with these tips and also check out our 6 overhead crane safety tips to protect your workers.

- You may be interested in: 10 safety precautions when using lifting equipment

What OSHA is saying about cranes’ safety operations

OSHA offers some guides and regulations around many modern cranes’ safety. You can check the following links to get more information:

- Lifting equipment with rated lifting capacity

- Ground conditions for hoisting and rigging

- Rigging equipment for material handling

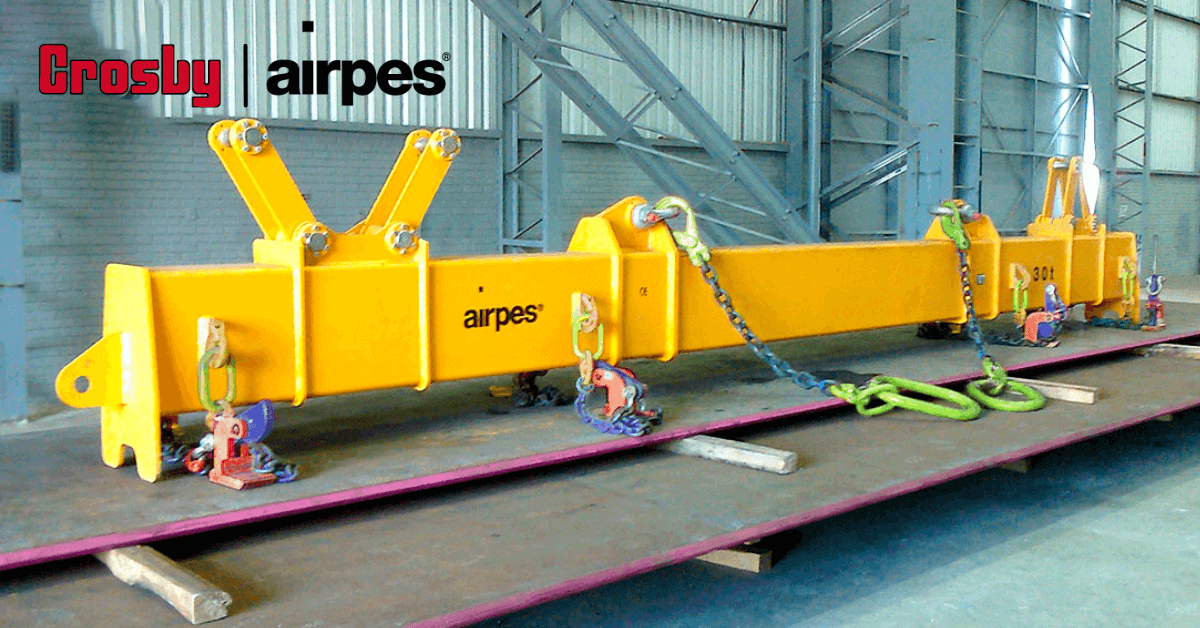

The safest handling and weighing equipment

At Crosby Airpes we take safety very seriously. We follow all current regulations and we make sure to test the equipment before you can use it.

You can also use our test bench service to ensure that your equipment is safe and properly calibrated.

If you want to know more, don’t hesitate to contact us. We will listen to your situation and will advise you with the best option for your company’s projects.

FAQS about the overhead crane safety

1. What are the most common crane accidents and how can they be prevented?

The most common crane accidents and tip overs result from improper equipment use, lack of pre start checks, and failure to account for the weight the crane can manage. To prevent these, ensure crane operator certification is up to date and that load limits are strictly followed.

2. How can I ensure the ground is safe for crane operation safety?

Start by inspecting the center of the crane’s operation area and confirming there are no potential hazards. Using a crawler crane or a rough terrain crane for uneven surfaces and outriggers for additional stability helps ensure safe operation. Outriggers and regular checks are essential for maintaining safe operation.

3. What is the importance of load charts in?

Load charts provide essential information, such as the crane’s rated capacity and the load radius, helping operators select the right crane for the job. Miscalculating the weight the crane can handle increases the risk of tipping over. In the construction industry, big loads require precise calculations to avoid accidents.

4. What should a pre-start checklist include for crane operations?

A complete checklist should cover:

- Pre-start checks engine and brakes functionality.

- Ensuring the crane operator reviews lift load charts.

- Verifying that the lift situation is free from hazards.

- Confirming that the weight the crane can manage aligns with the planned load.

This ensures proper handling throughout the lift and helps operators comply with safety and health regulations.

5. Why is it important to select the right crane for the job?

Choosing the right crane depends on factors like load radius, terrain conditions, and whether it’s a mobile crane or a crawler crane. For example, all terrain cranes are versatile for both smooth and rough surfaces, ensuring safety and efficiency in the industry.

6. How can proper communication improve crane safety?

Effective communication with qualified personnel is key. Using hand signals or a signal person ensures smooth coordination, especially during complex lifts involving irregular and heavy loads. Proper communication reduces the risk of accidents and tip overs.