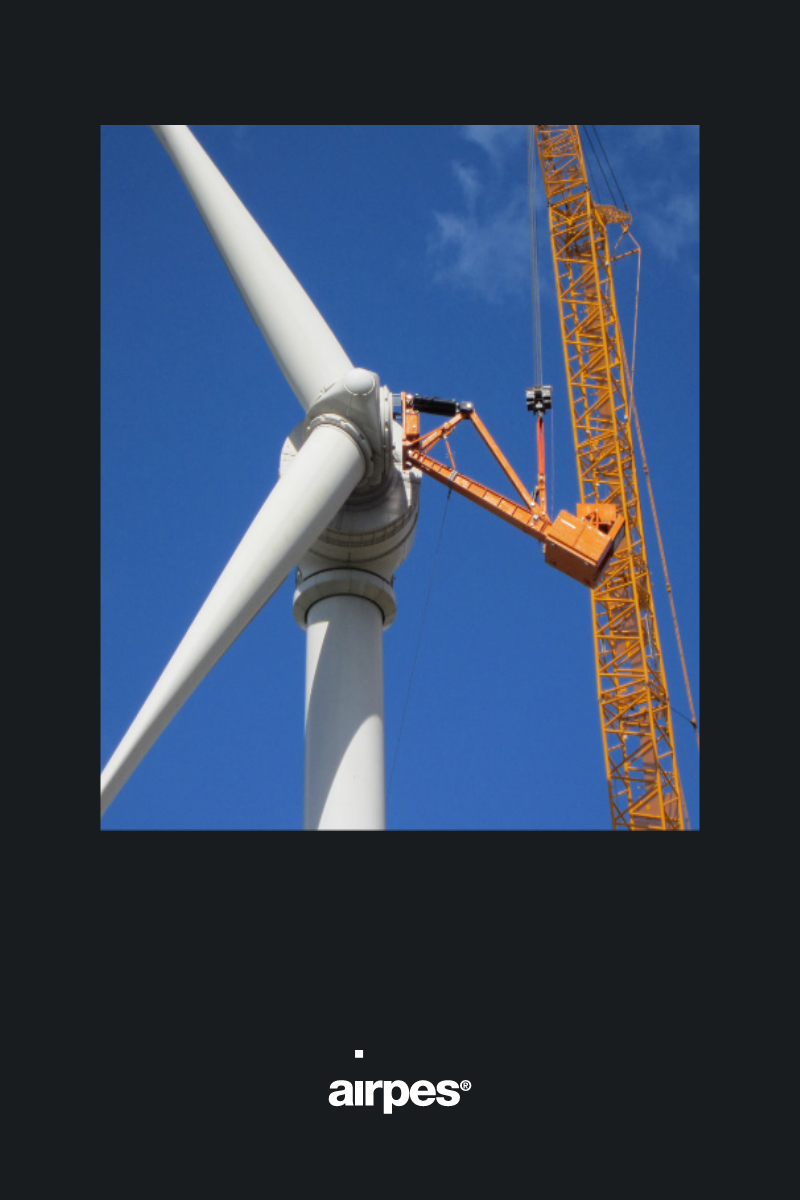

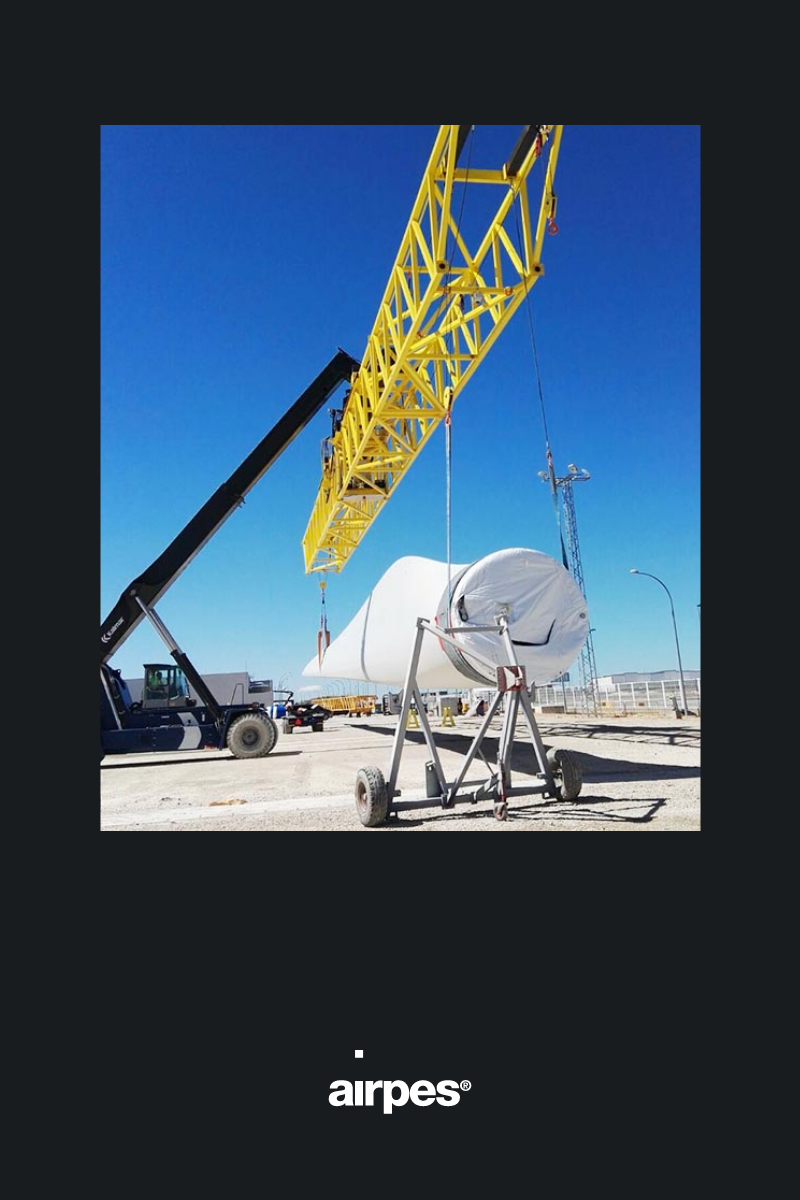

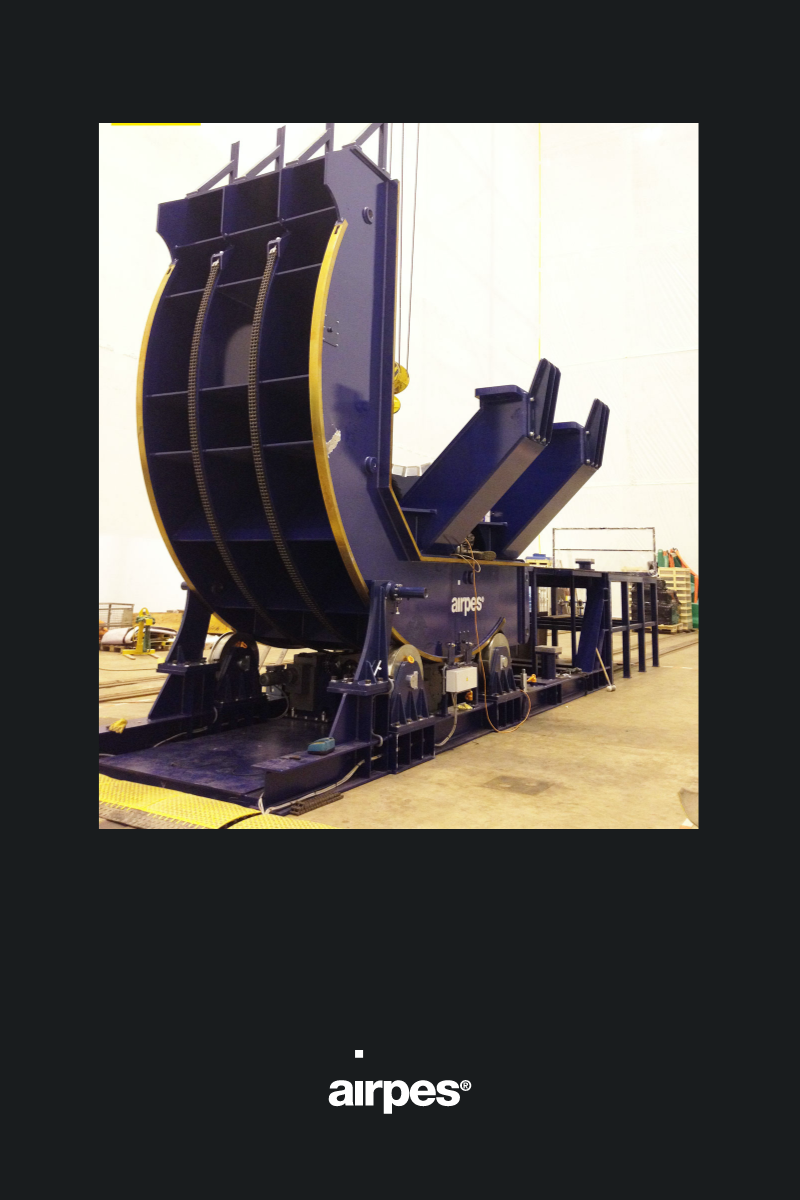

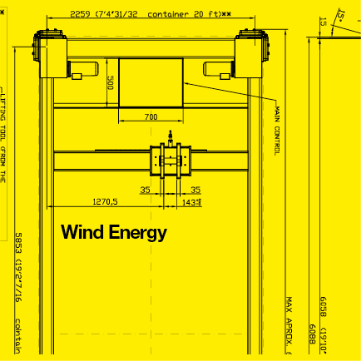

2x50t rail transfer cars for wind turbine plate roll in Brazil

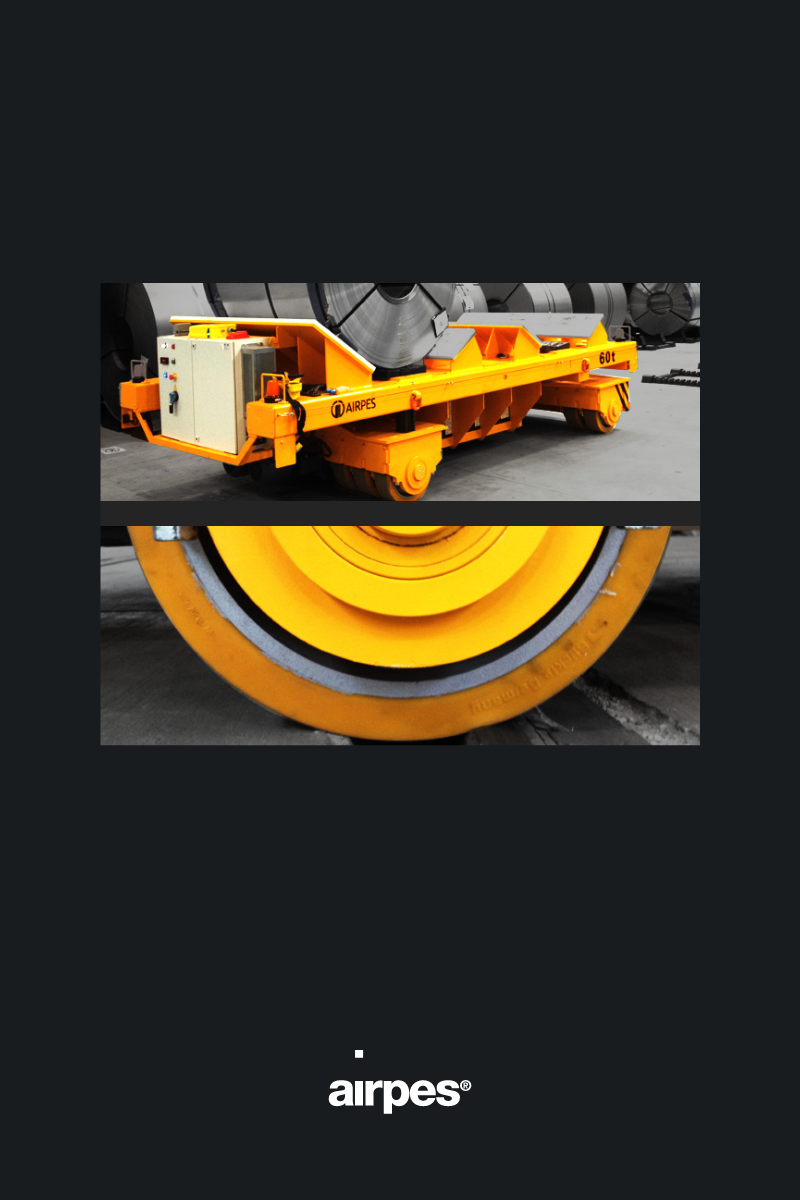

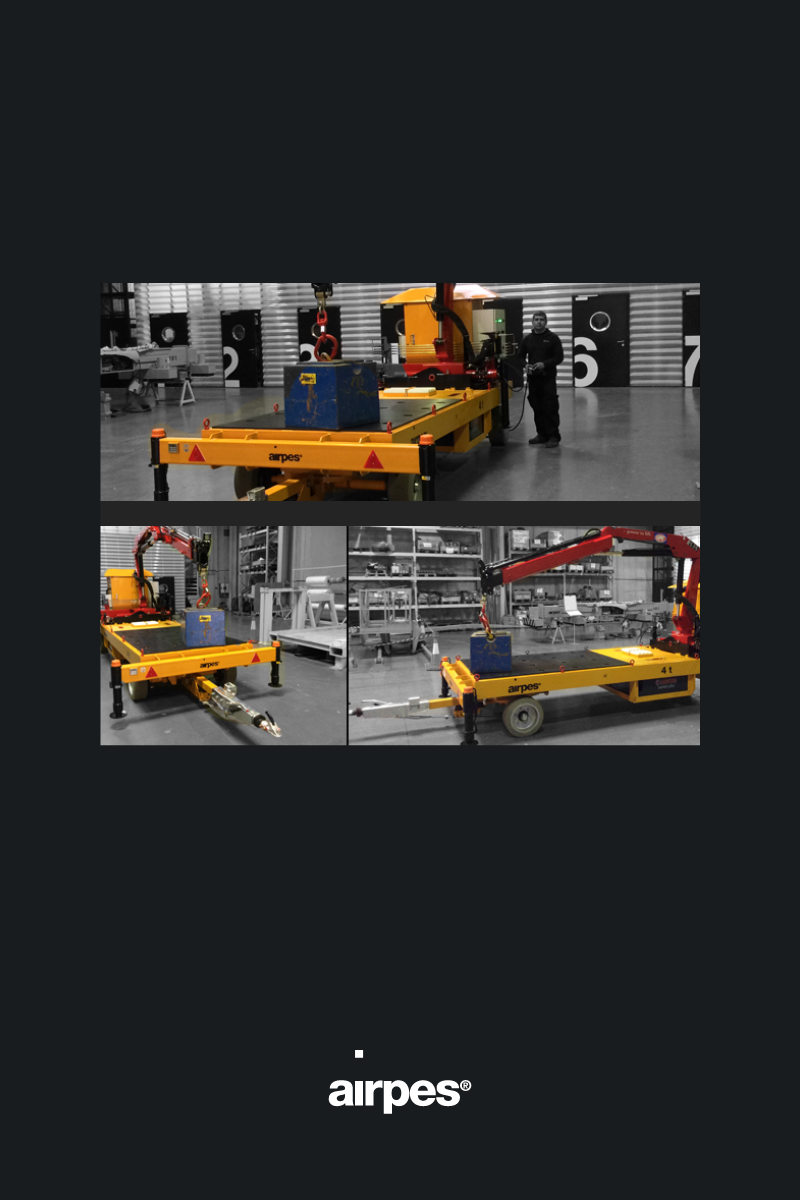

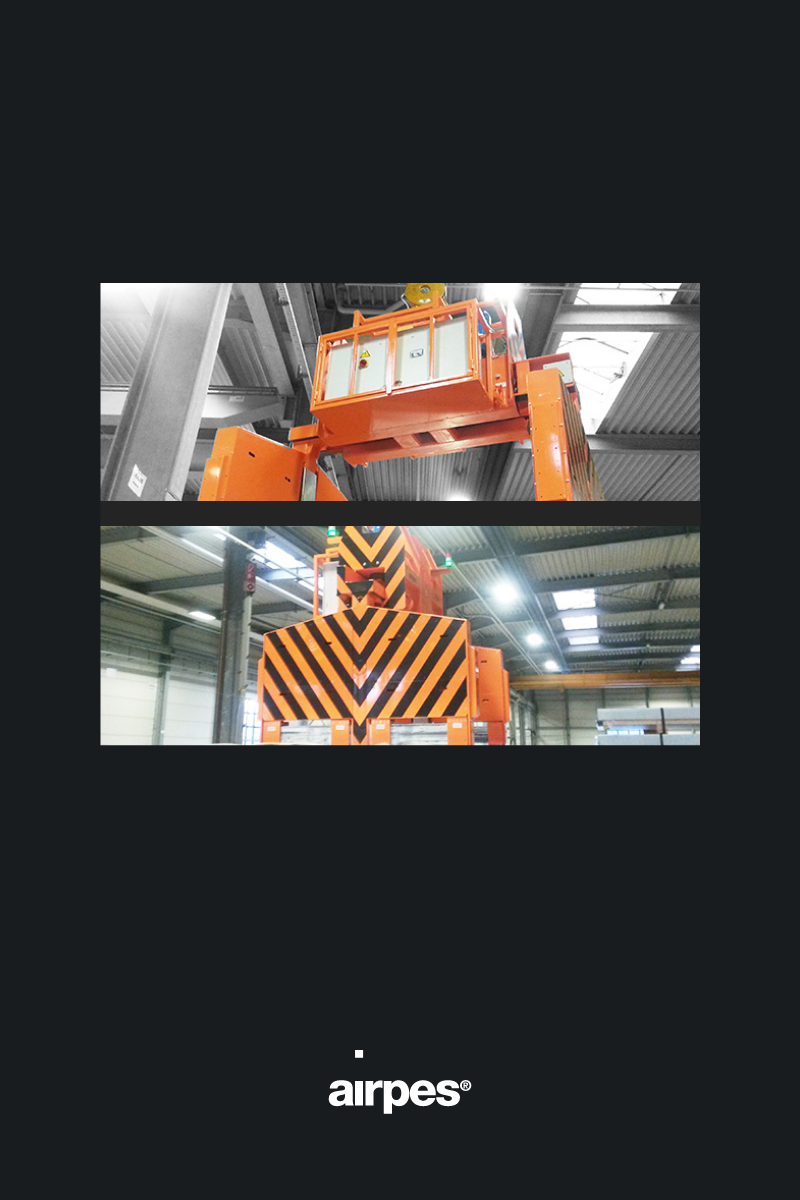

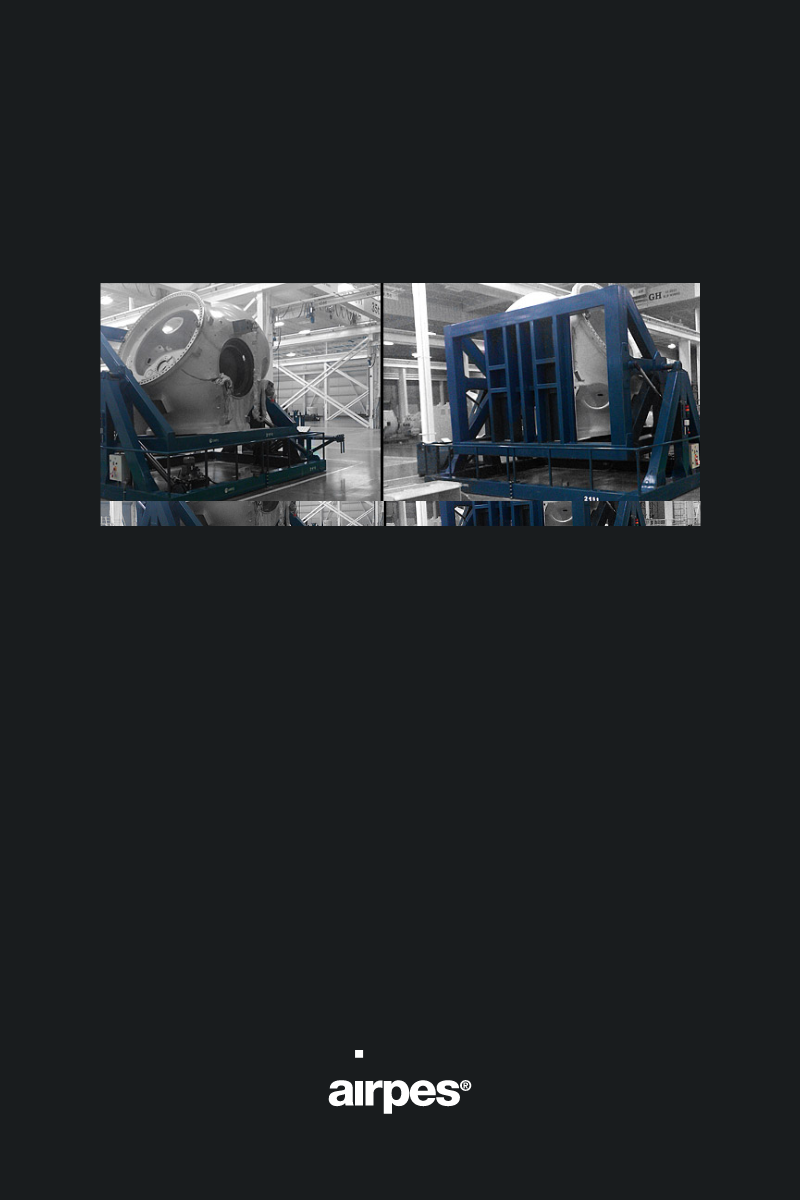

Design, manufacturing, testing and installation of a system composed by two independent cars with storage support.

Initial situation description

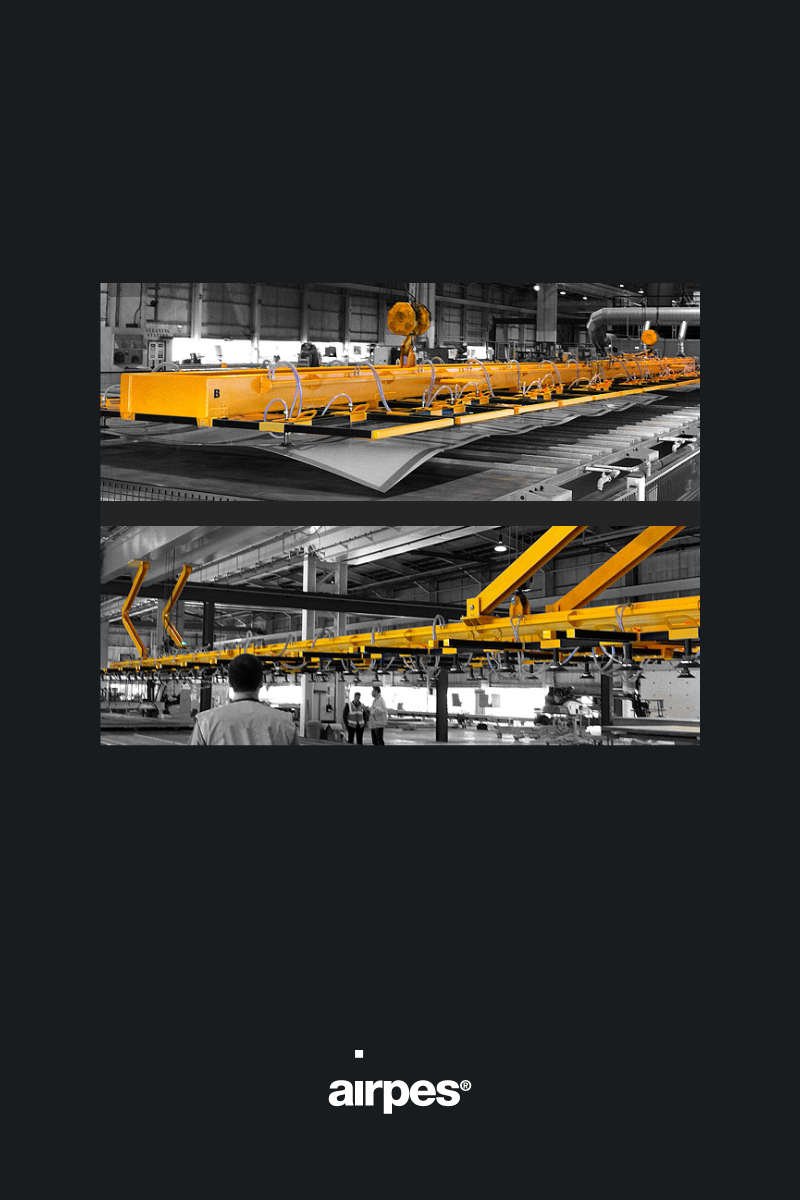

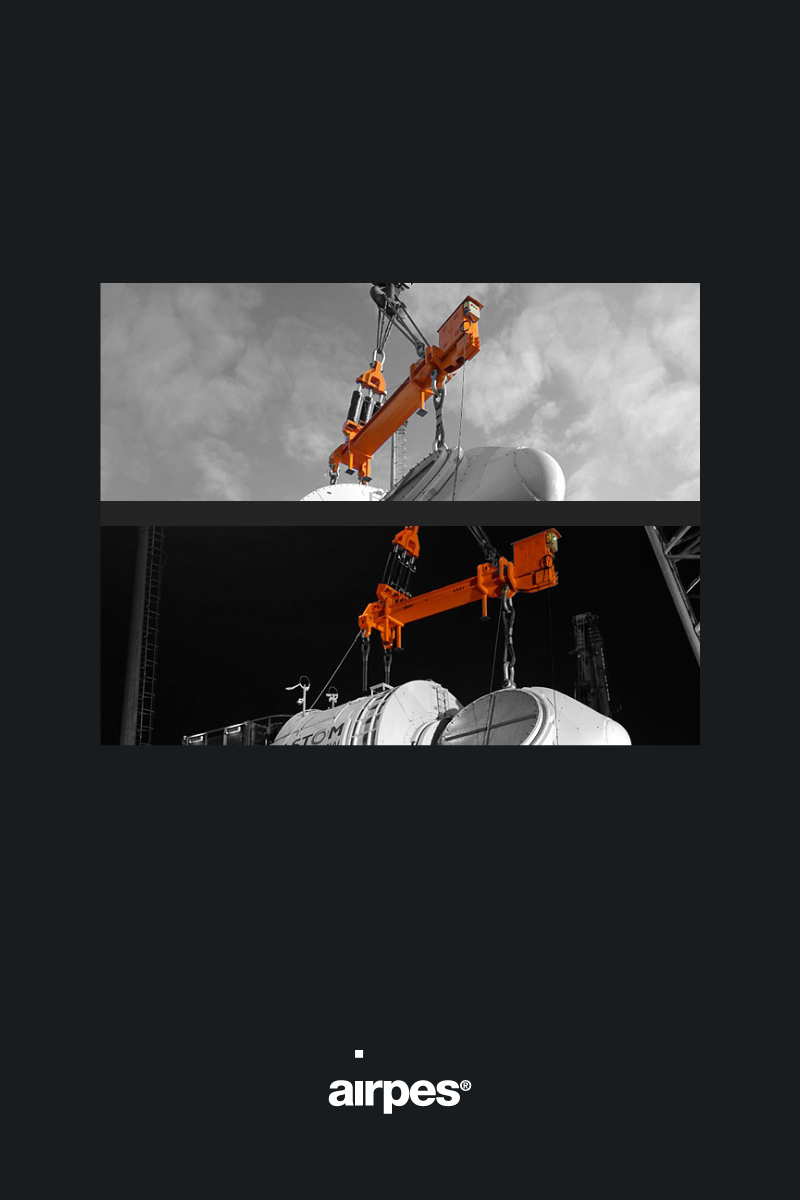

Extremely difficult transportation of the wind towers plate roll (external diameter between 2.000 mm and 4.500 mm) across the production area.

Need to solve

Main problem was that the ferrule needed to be removed from the production unit, at a different height, and transported 60 meters.

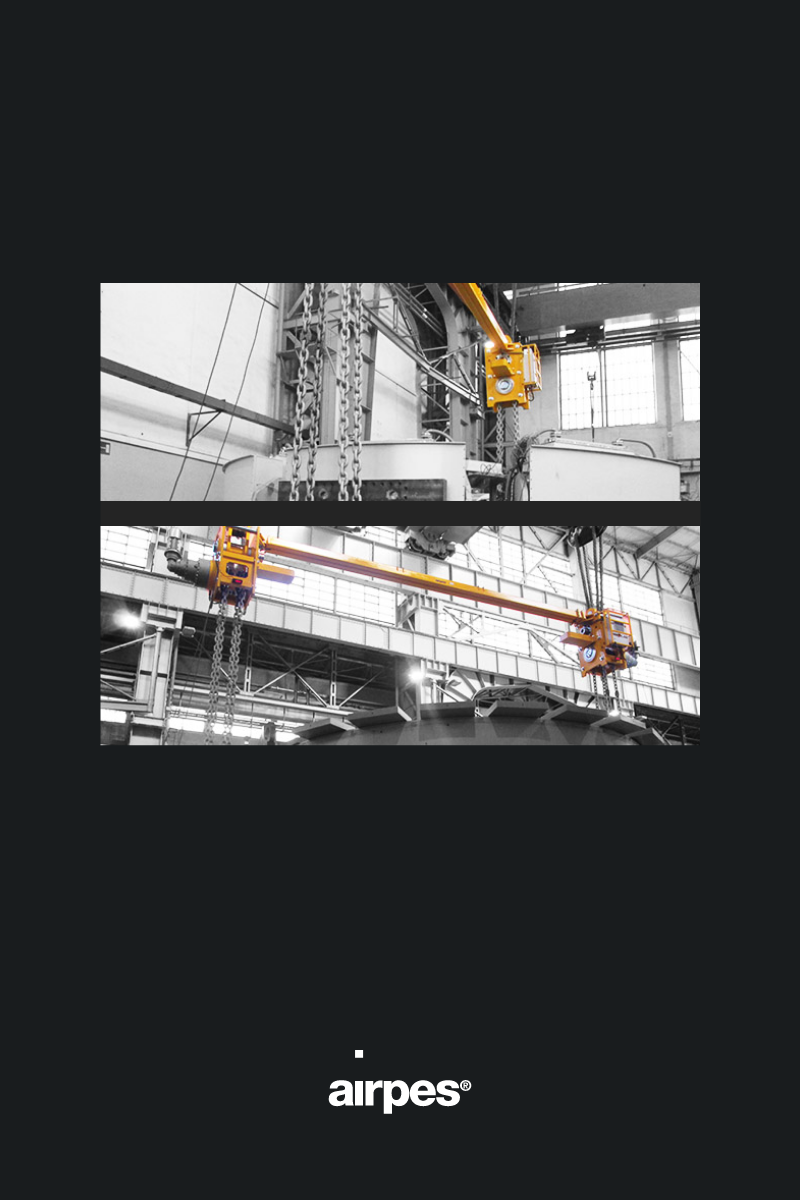

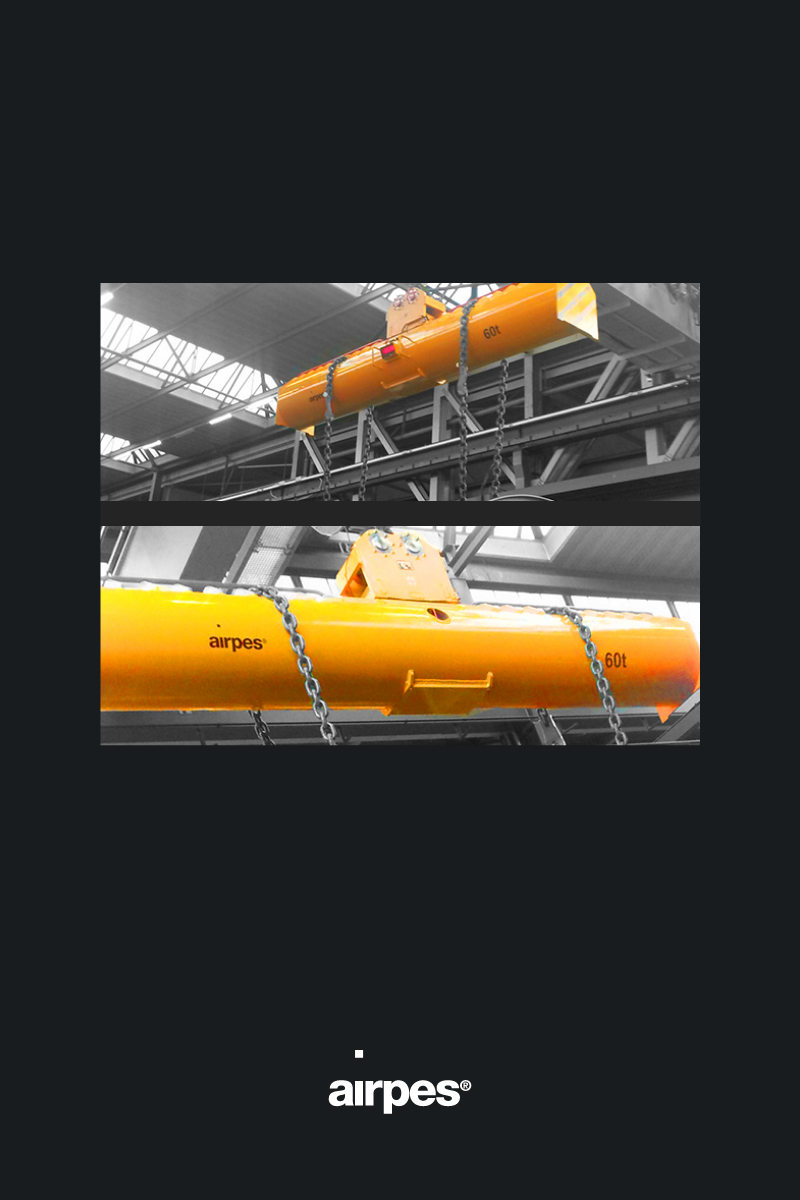

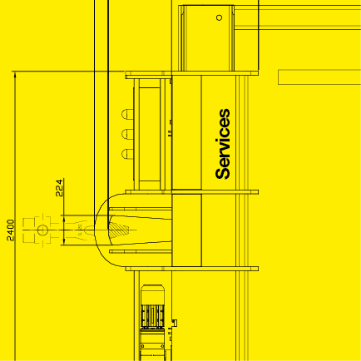

We designed, manufactured, tested and installed a system composed by two independent cars with a storage support for the plate rolls that can be lifted up hydraulically from 800 mm up to 1.400 mm, to remove the ferrule from the production unit and lift it down for the transport. The capacity of the two cars is up to 100t (2X50T each)

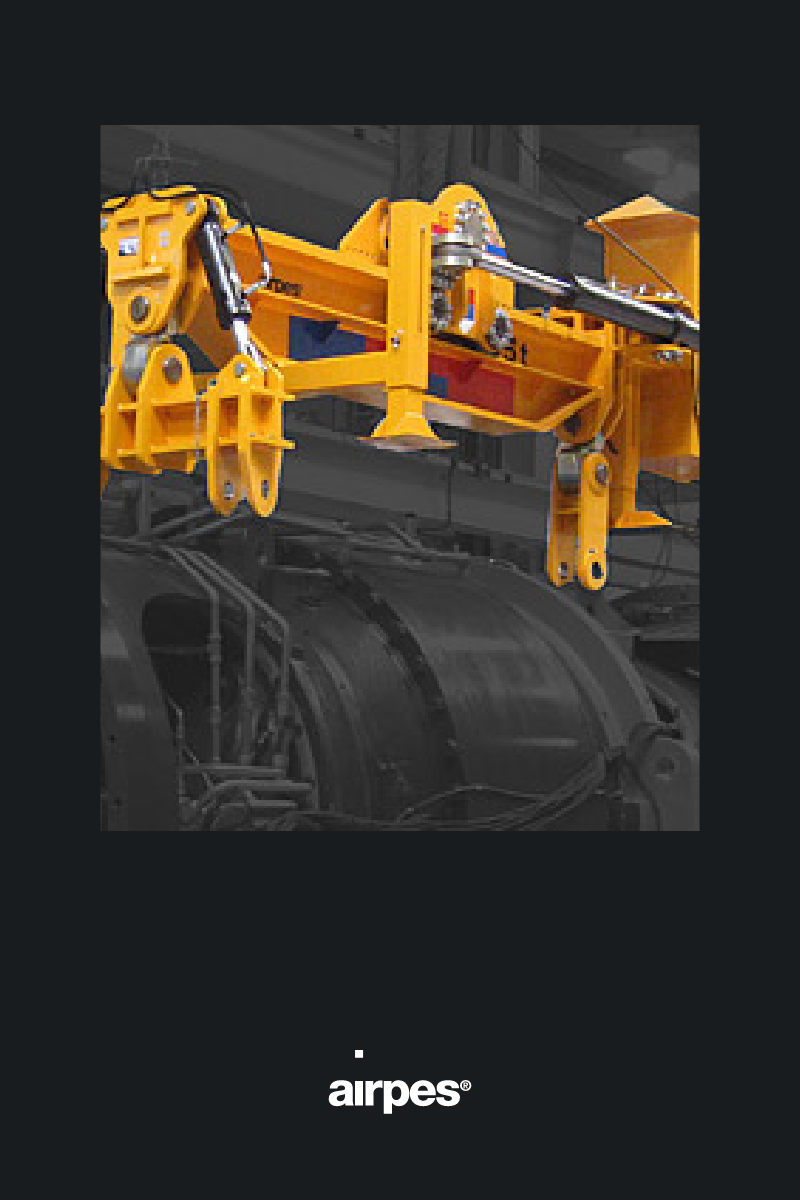

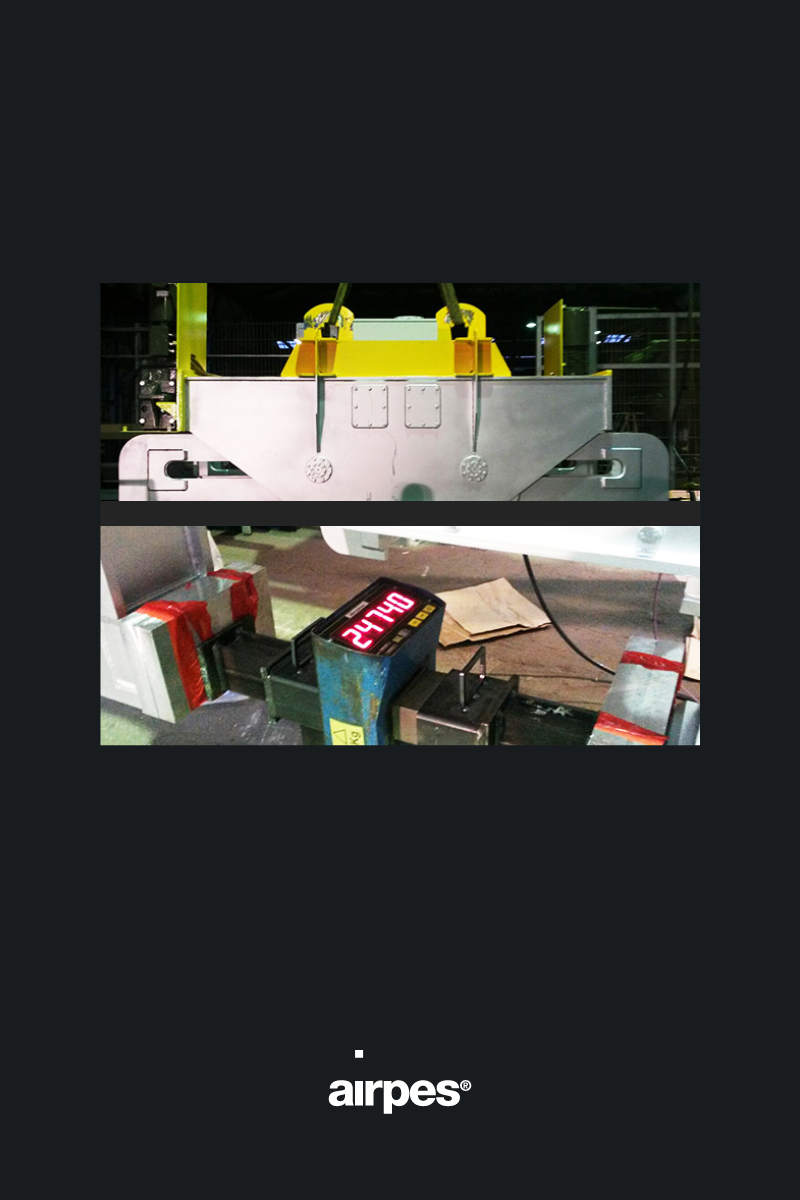

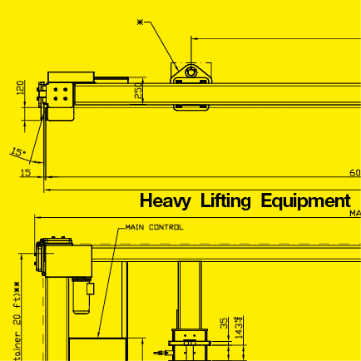

Safety and control system was composed by:

- Radio remote control by joystick with data feedback on the radio remote

- Control of distribution of the weight on each trolley

- Synchronous movement of the cars via Wi-Fi, and positioning by using Götting reader and Tags installed on the rails ↔ car speed control

- Cars equipped with security bumpers (front/back).

- Ferrules Handling with extreme care.

- Global safety system (also in the cars) allows doing maneuvers faster and safer..

OUR on demand solutions

Airpes Solutions

LATEST POSTS ON THE BLOG

Discover our brand new developments, events, get posted of our activity.

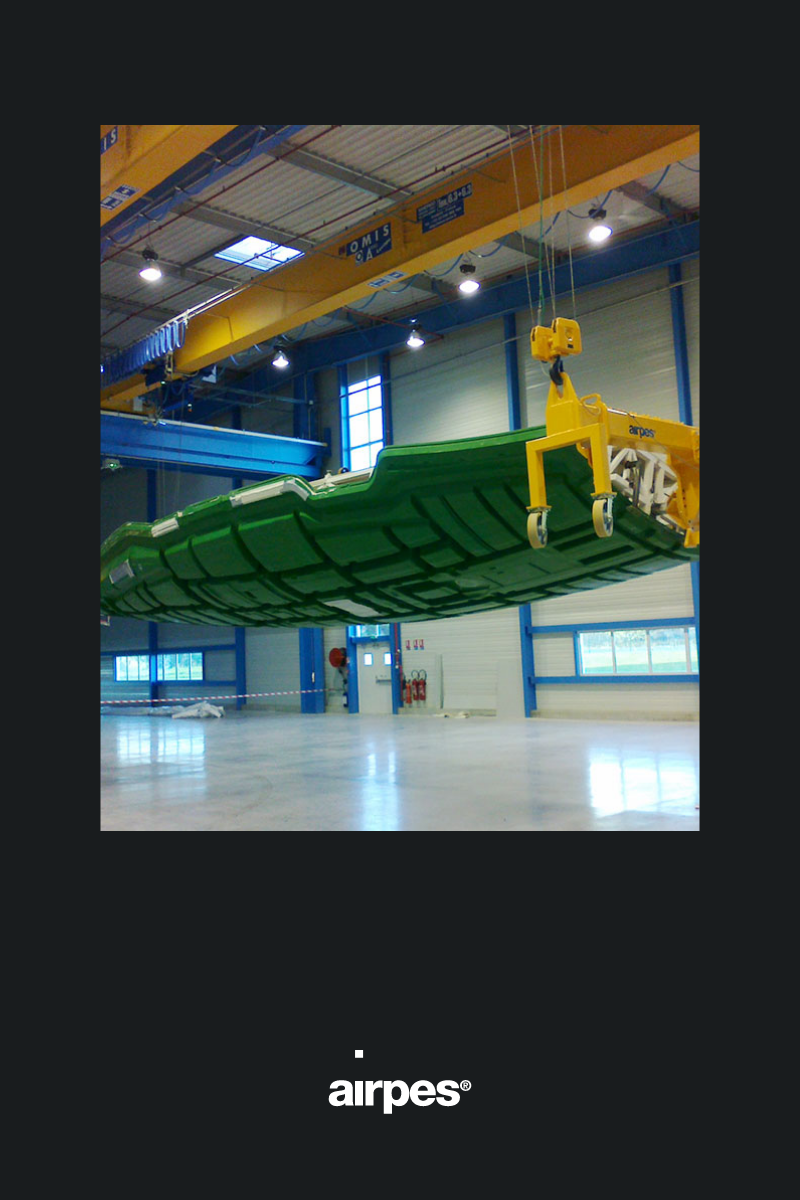

- Boost your container handling with hydraulic lifting spreader beamsDiscover how our hydraulic lifting spreader beam transforms container handling operations. Adaptable to 20", 30", and 40" containers,...

- Types of crane hooks for liftingChoosing the right crane hook ensures safe and efficient lifting operations. Discover the different types, their specific applications,...

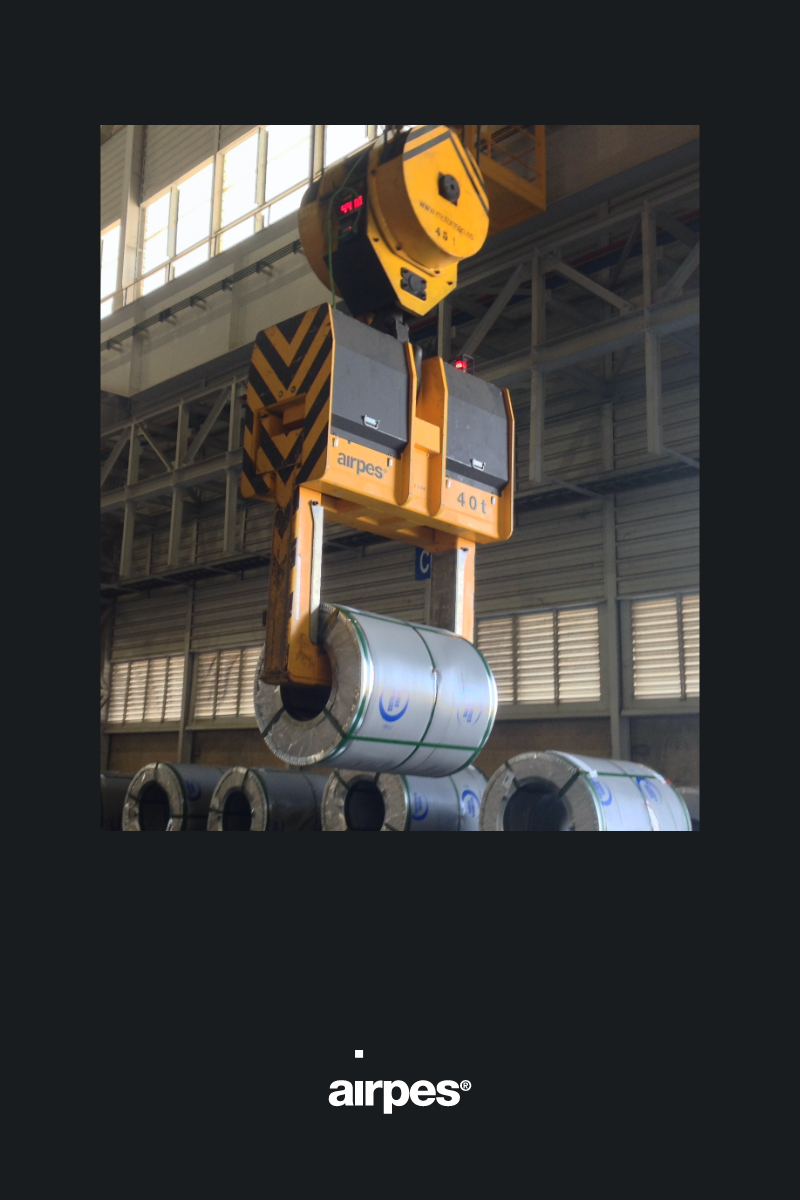

- C-Hook for lifting metal coilsLooking for a reliable way to lift heavy metal coils? This robust lifting solution, engineered by Crosby Airpes,...

- What are the five principal wind turbine parts?Wind turbines consist of five main parts: the foundation, tower, rotor and hub, nacelle, and generator. Each component...