FT 3117 WINCHE

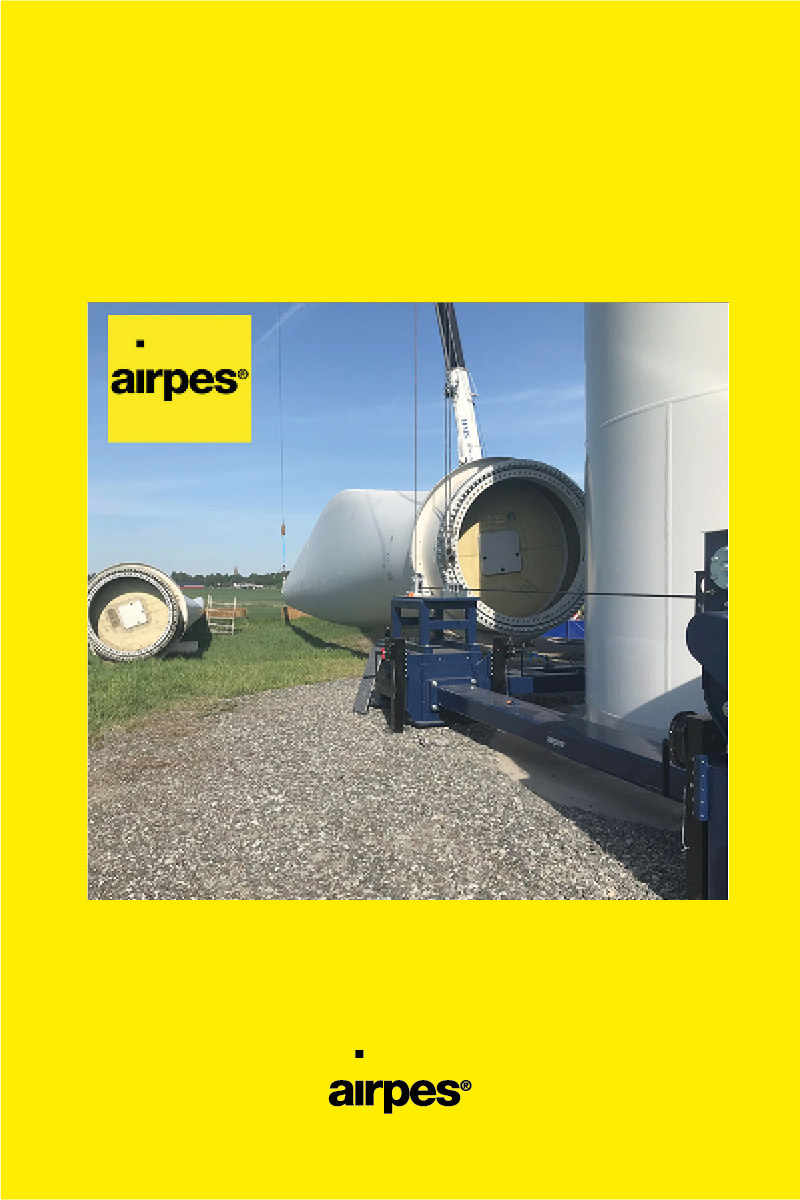

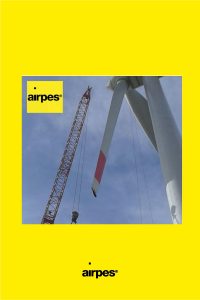

Airpes has developed its own integral crane-less solution, possible to be adapted to many wind-turbines, developing design, engineering, calculations, regulations, winch control system, remote control, software, prototype and tool deployment.

In Airpes we have designed a lifting method that uses the structure of the wind turbine as a support point. We have designed a solution that only with cables and tightens to the base of the generator on the ground will lift (or descend in the case of reparations) the turbine blade in a few minutes. That allows the company to repair or replace a blade in just a fraction of the time it would need with the other methods.

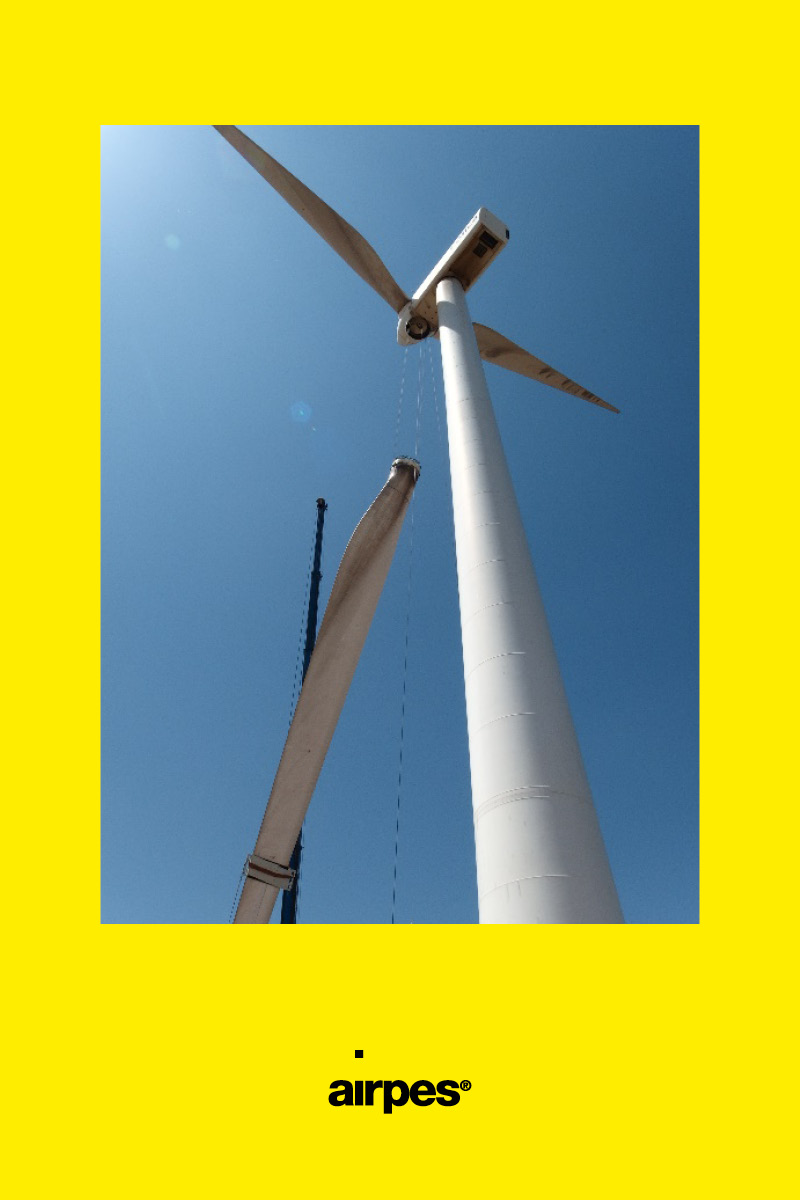

When the tower and nacelle are correctly assembled it is the turn to lift the rotor and then the blades. A few years ago, when wind turbines were relatively small -which is less and less common- the hub would be mounted with the blades already attached, but today we have large and heavy wind turbines, so lifting the rotor with its three blades already attached is an impossible task. It is a large structure: tens of tons of weight that must be lifted to more than 100 meters high.

In these cases, the hub is first lifted and installed and then the blades are attached to it one by one. Precisely to carry out this task, Airpes has designed a system for lifting wind turbines without a crane, using the structure and the tower of the wind turbine as support. As well as simplifying the task we reduce the cost of assembly: the price per hour of renting a high tonnage crane is extremely high.

Total Control

With our tool and our broaden experience in the Lifting sector, you would have total control over the blade installation process. Thanks to multiple sensors and electronic devices, like load cells, wind speed, encoder for the drum’s length, etc… you will know the status of your blade, at any moment.

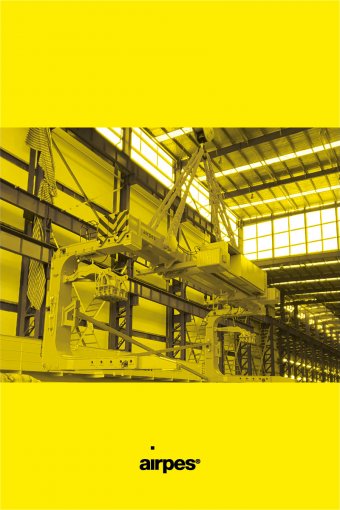

Electro-mechanic Solution

Much more than a simple winch. Thanks to our electro-mechanic activated drums, the winch controls the blade lifting while checking that the rope is tight at any moment.

Multi-configuration

This tool can be configurated to adapt to different weights (counter-weight adjustment) and to different blade’s interfaces; by flanges, by rings, etc… so we can meet your most comfortable solution

Tailor-made re-adaptation

Each wind turbine manufacturer has their own strategy in the Wind Industry, and we adapt to all of them. Thanks to a pre-study and as per your requirements, we can meet your necessities to

For blade exchange, no matter what

This tool does not require, as other solutions we have developed, the blade to be at any precise angle, so if your bearing is broken, your blade, or you cannot move your system for any reason, our crane-less can be your solution.

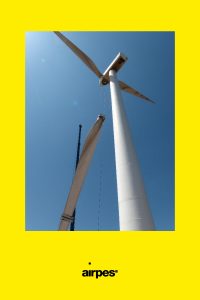

Totally Orientable

The tool can be oriented around the tower section, so we can align with the nacelle and bring down (or up) the blade.

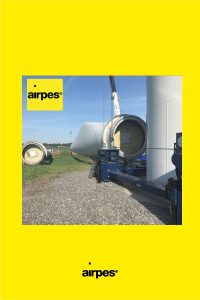

Easy to transport

It can be transported in just a 40ft. Container only*

(*) Depends on your re-adaptation

Cheaper than a crane

Cheaper than paying a daily crane rent per day, ask us about our crane-less renting service.