LIFTING BEAM

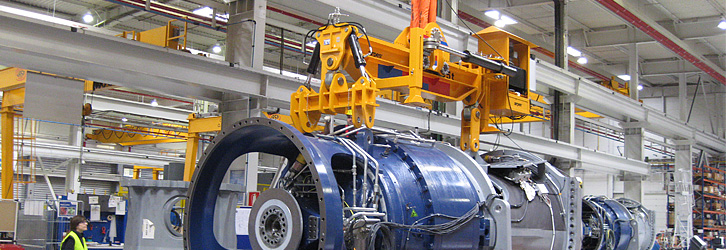

High-Performance lifting beams by Airpes

Airpes® specializes in designing and manufacturing lifting beams tailored for industrial lifting operations. We provide a comprehensive range of lifting solutions, including:

- Fixed lifting beams

- Adjustable lifting beams

- Spreader beams

- H lifting beams

- Lifting beams with moving center of gravity

- Hydraulic-powered lifting beams

- Lifting beams with leveling systems

- Motorized rotating lifting beams

Each crane lifting beam is designed to enhance load handling efficiency, safety, and durability while meeting industry regulations.

What is a Lifting Beam?

A lifting beam is a robust metal structure used to distribute the load’s weight evenly, improving lifting stability and safety. It is connected to a crane hoist using rigging systems such as chains, slings, and shackles. Lifting beams are commonly used to handle unbalanced loads or uniquely shaped objects that cannot be lifted with a standard hoist system.

They are widely used in heavy-duty lifting operations across industries such as aeronautics, steel mills, and wind energy.

Lifting Beam vs. Spreader Beam

Both lifting beams and spreader beams improve load handling, but their structural differences impact performance:

- Lifting Beam has a central attachment point and is ideal for low headroom applications.

- Spreader Beam utilizes multiple lifting points, reducing bending forces and offering higher load stability.

Types of Lifting Beams for material handling

At Crosby Airpes, we engineer custom lifting beams to meet specific industry needs. Here are the main types:

Standard Lifting Beams

- A single bail at the center, where the crane hook connects.

- Can be adjustable to reposition the center of gravity.

- Suitable for lifting tongs, electromagnets, and slab handling.

- Ideal for low headroom spaces.

- Limitations: higher bending forces require stronger material construction.

Spreader Beams

- Two or more attachment points for better load distribution.

- Transforms bending forces into compression forces, increasing structural strength.

- Recommended for heavier loads when sufficient headroom is available.

- Limitations: requires additional rigging space for slings or chains.

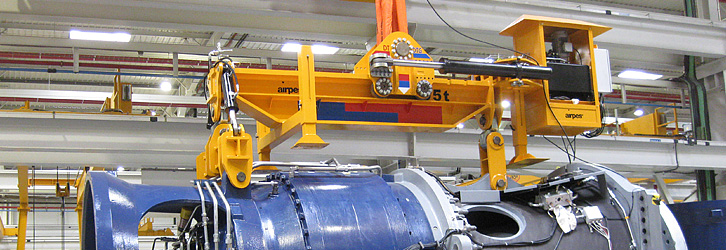

H Lifting Beams

- Designed for handling oversized or irregular loads.

- Distributes weight to four lifting points, ensuring greater stability.

- Commonly used in steel and aeronautics industries.

- Limitations: more complex design and manufacturing process.

Benefits of Airpes Lifting Beams

- Custom engineering to match your lifting requirements.

- High-strength steel construction for durability and safety.

- Compliance with EU safety standards (UNE-EN ISO 9001:2000 – TÜV Certified).

- Low maintenance and long service life.

- Integration with hoist systems, electric chain hoists, and pallet lifters.

- Compatible with various cranes, including overhead cranes, gantry cranes, and jib cranes.

Industries That Benefit from Lifting Beams

Airpes® designs lifting beams for multiple sectors, including:

- Renewable Energy: wind turbines, nacelles, eolic rotors, and windmill blades.

- Steel Industry: heavy-duty coil lifting beams for steel mills.

- Aerospace & Aviation: safe transport of sensitive components.

- Paper Mills & Manufacturing Plants: custom lifting solutions for production lines.

Frequently asked questions

1. How does a lifting beam differ from a spreader beam?

A lifting beam has a central attachment point, while a spreader beam uses multiple points for load distribution. Spreader beams reduce bending stress and provide better stability.

2. What accessories can be used with lifting beams?

Common attachments include:

- Lifting clamps

- Eye bolts

- Pallet lifters

- Ratchet lever hoists

- Electric chain hoists

3. What materials are used in lifting beam construction?

Most lifting beams are made from high-strength steel alloys, ensuring safety and durability in heavy-duty lifting applications.

4. Why are regular inspections of lifting beams necessary?

Routine inspections prevent equipment failure, ensure compliance with safety regulations, and extend service life.

5. What industries use lifting beams the most?

Lifting beams are essential for wind energy, aeronautics, steel mills, and paper mills, where heavy and oversized loads require specialized lifting solutions.

6. How can lifting equipment be customized?

Customization includes adjustable center of gravity, hydraulic-powered lifting, rotating beams, and automatic control systems for enhanced performance.

Get the best lifting solutions with Airpes

If you’re looking for a reliable, high-performance lifting beam, Airpes is your trusted lifting equipment supplier. Contact us today to discuss custom solutions for your material handling needs.