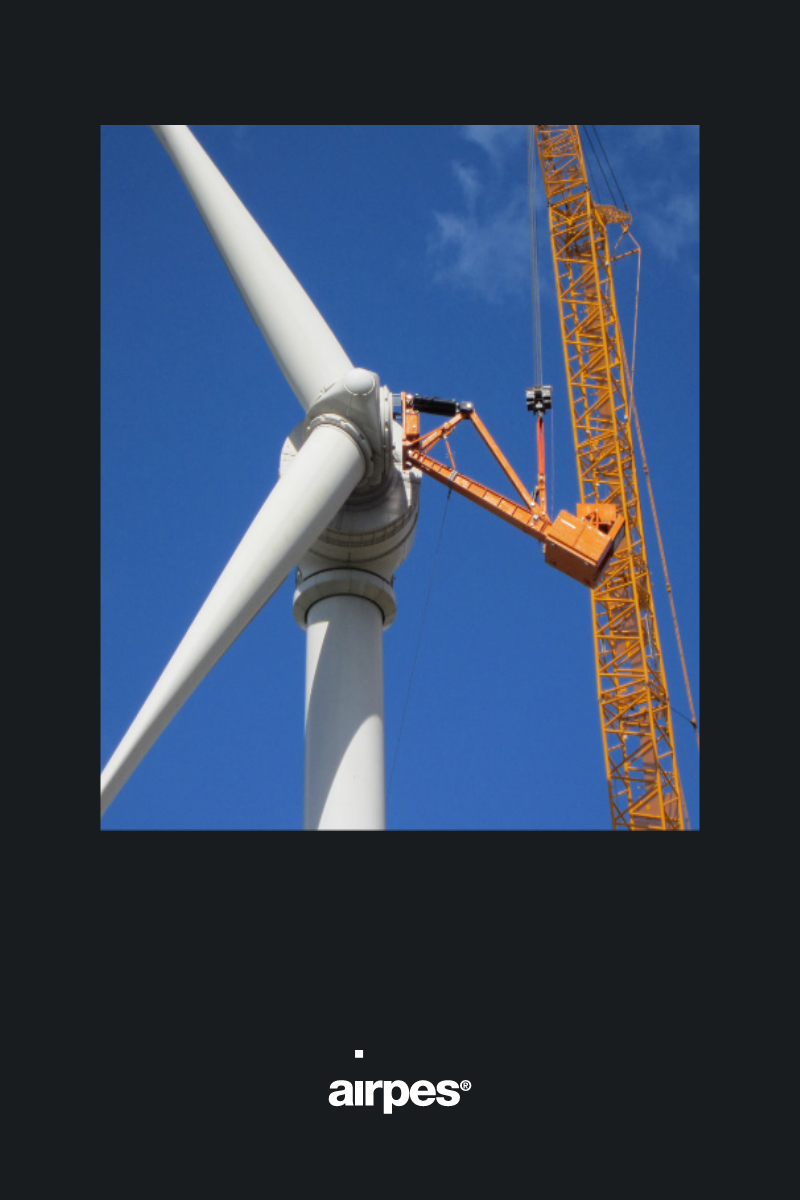

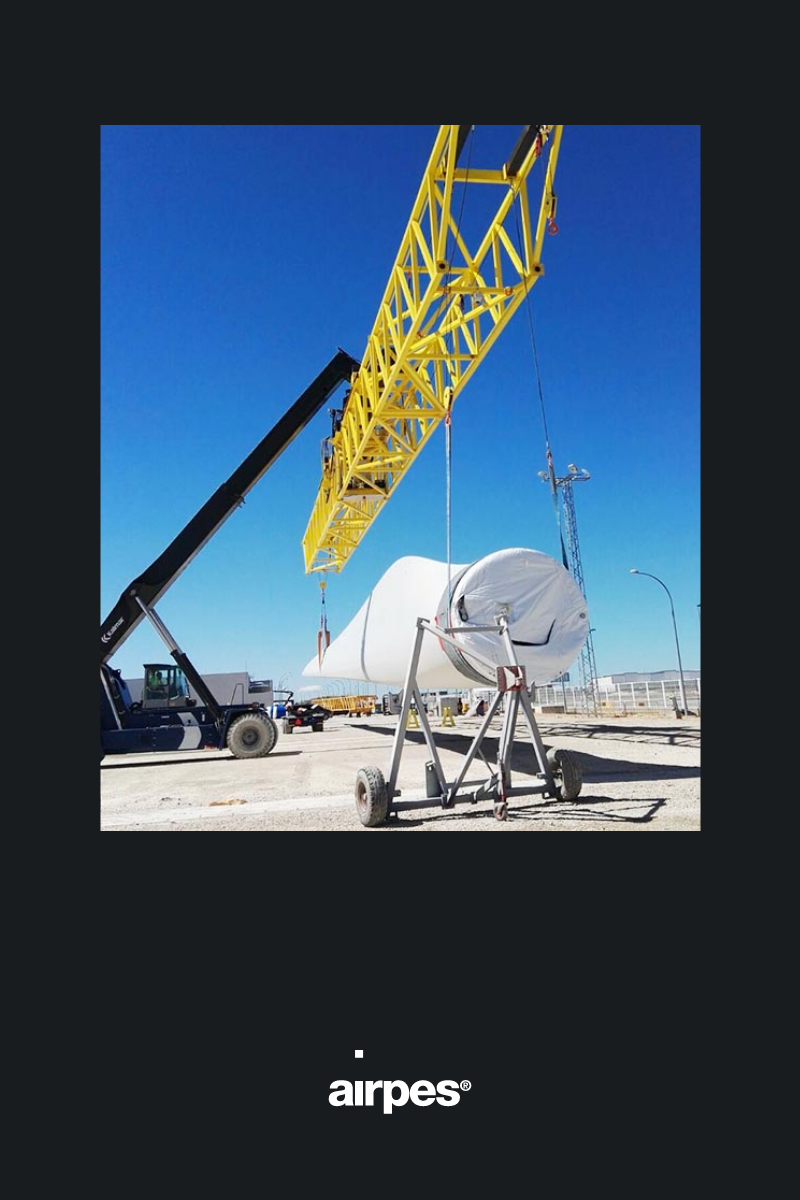

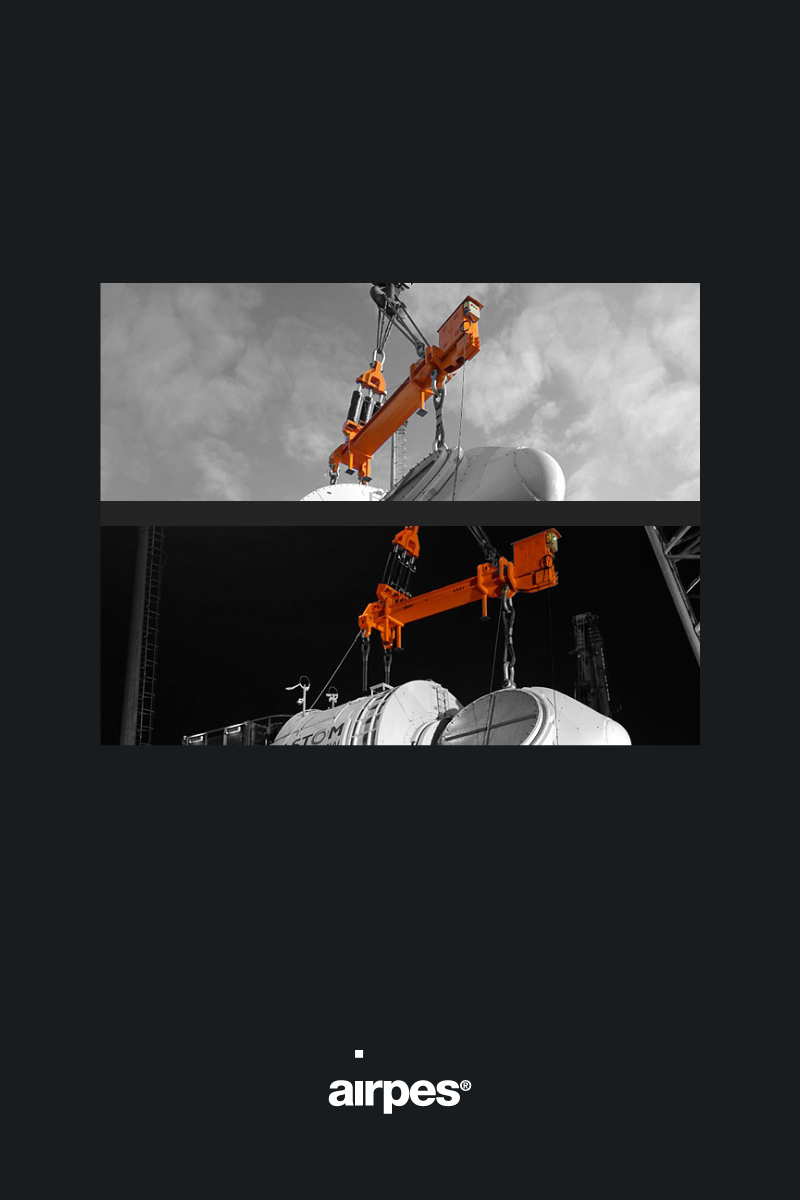

Wind Sector Project for a Brazilian Wind Turbine Towers Manufacturer

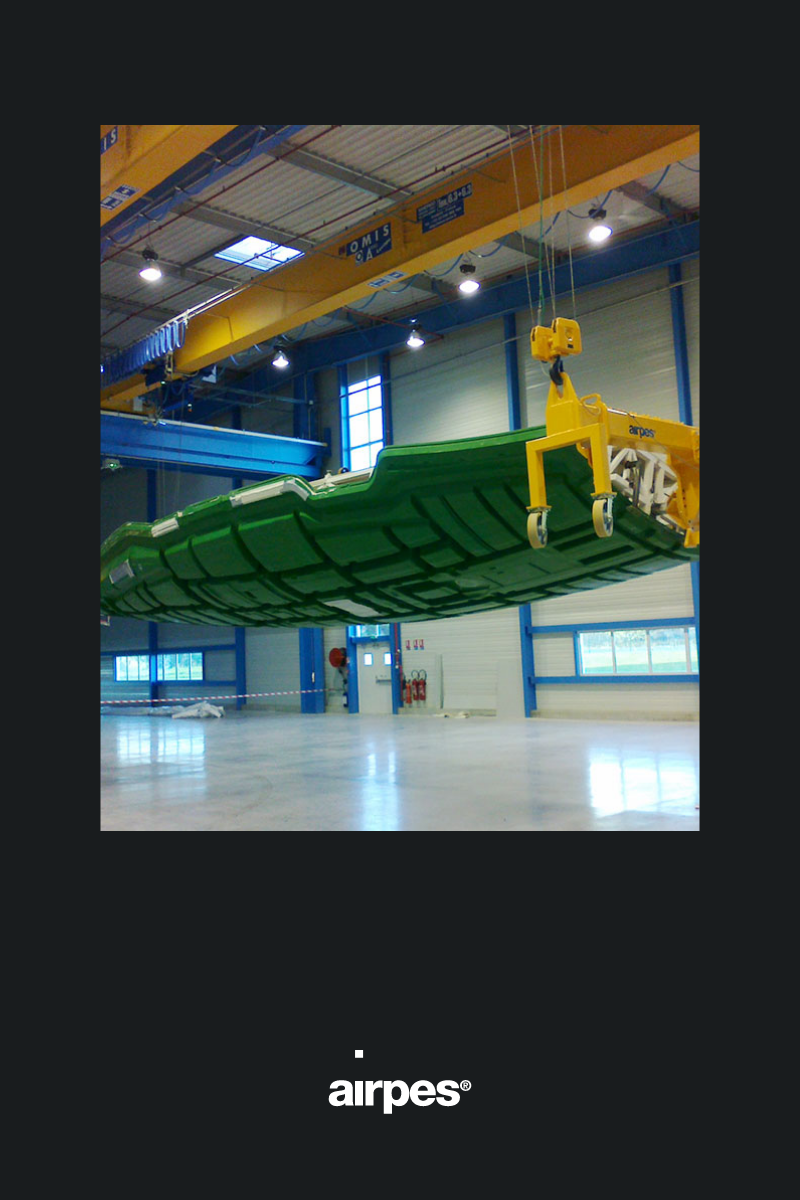

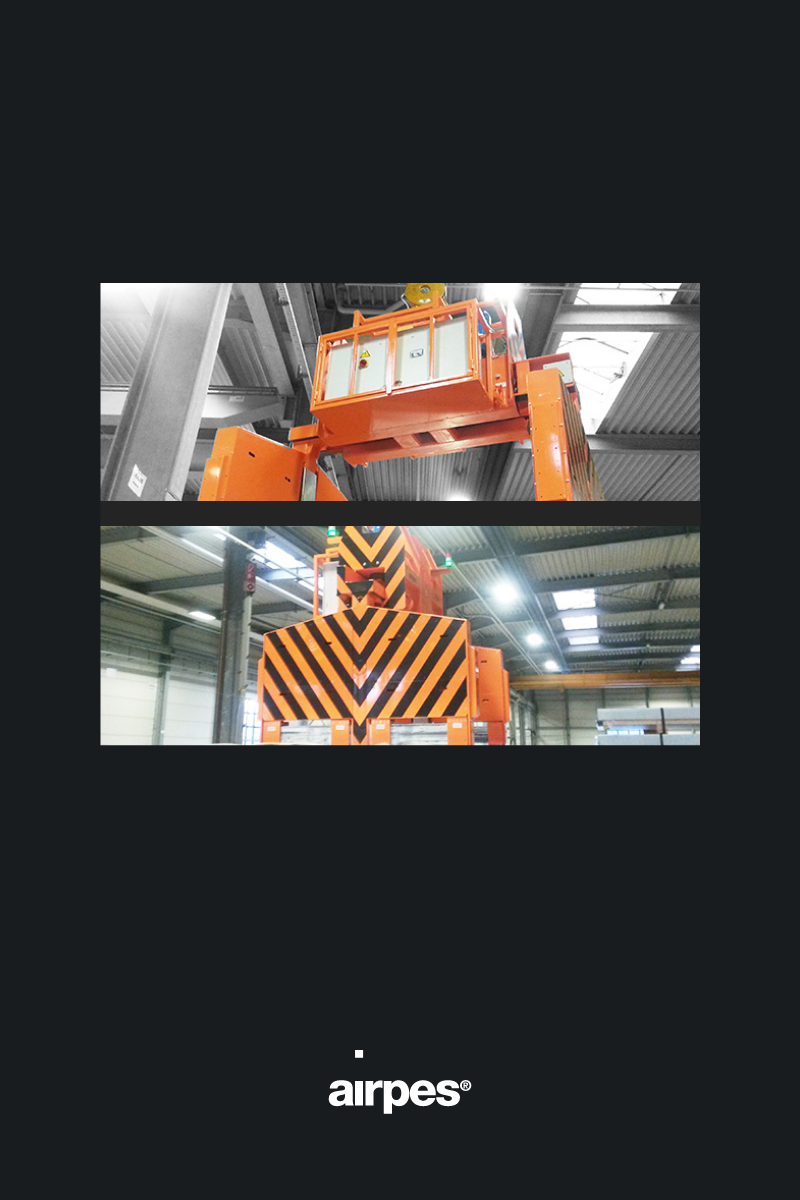

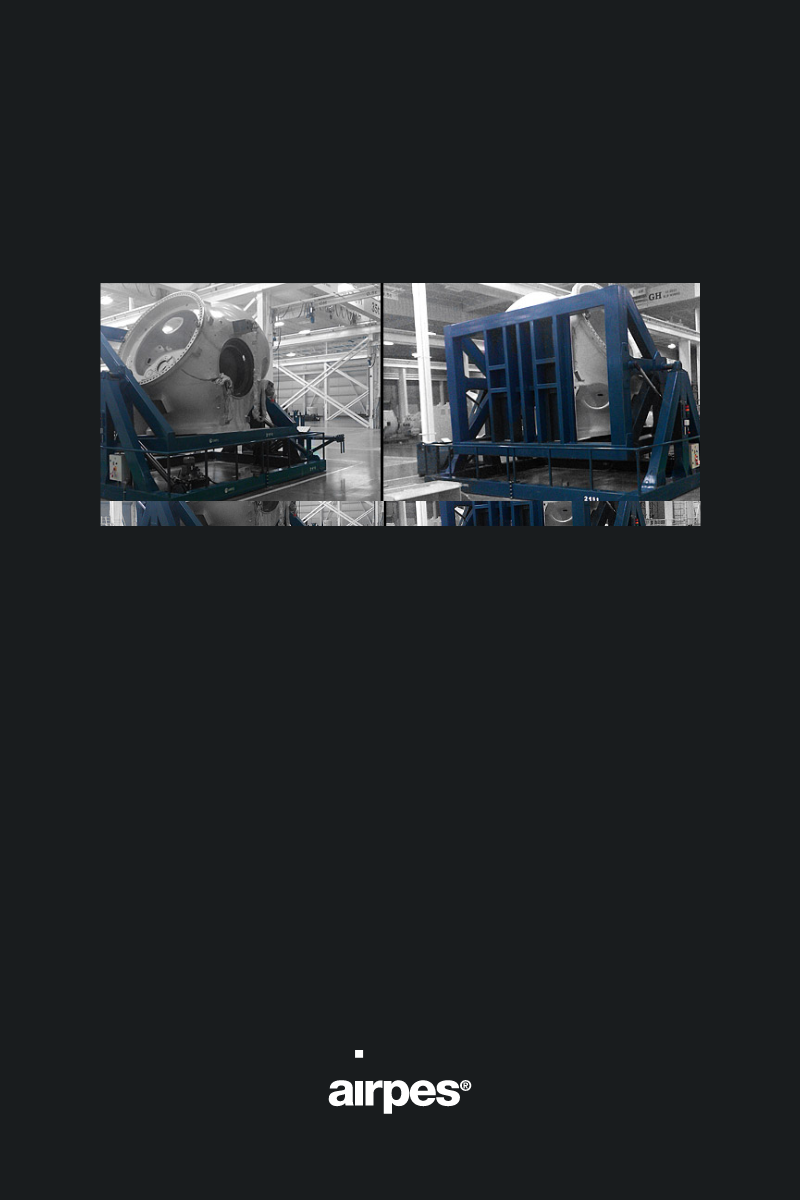

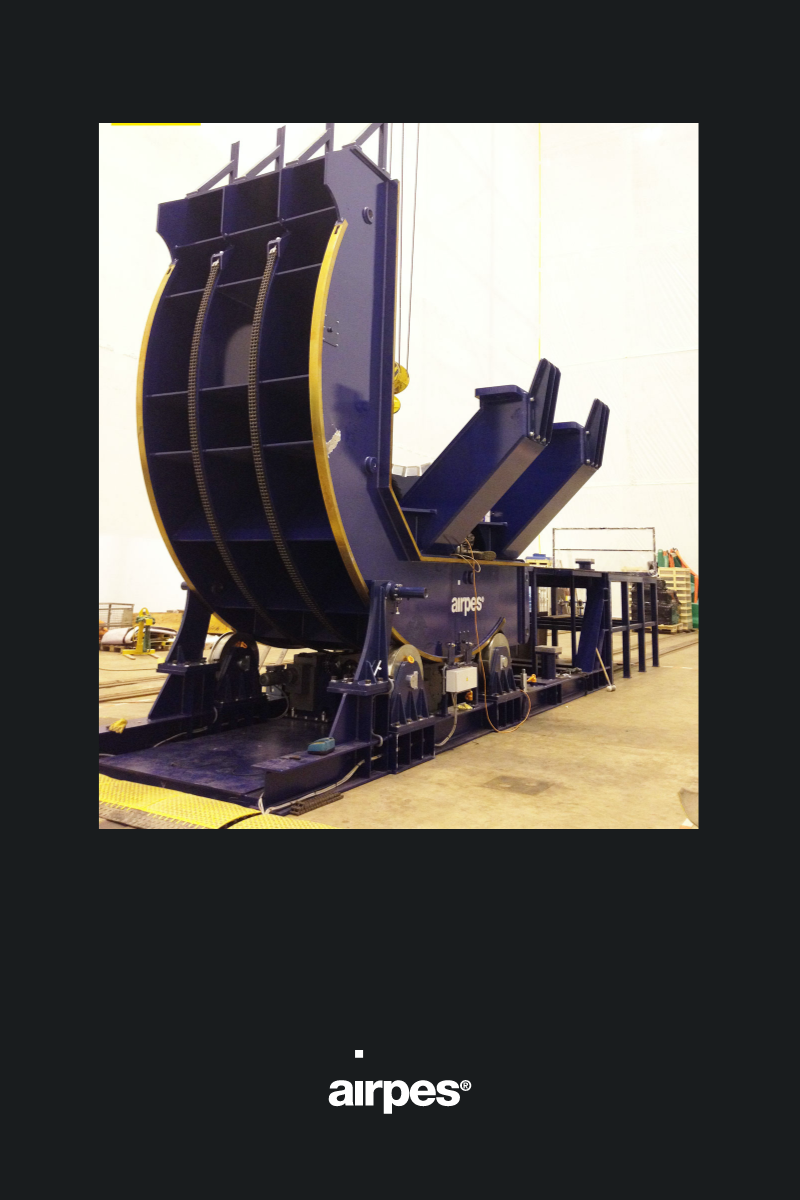

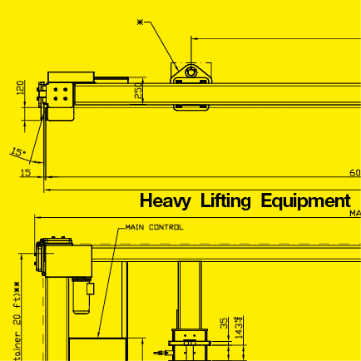

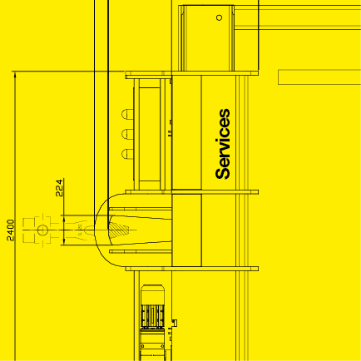

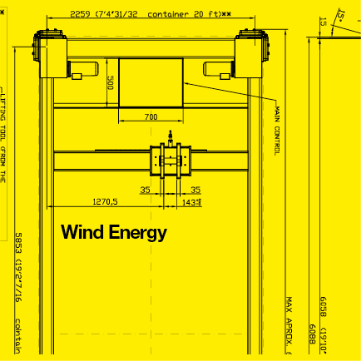

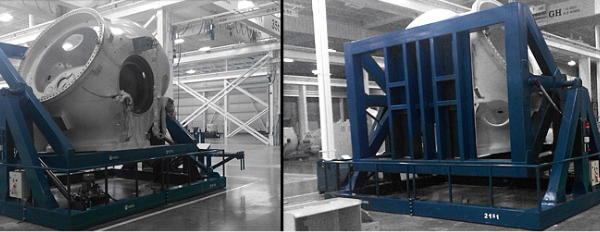

Today we present you a handling solution for a Brazilian Wind Turbine Towers Manufacturer, for which Airpes designed, manufactured and installed a rotator up to 21.5t in conformance with OSHA and UL standards.

Initial situation description

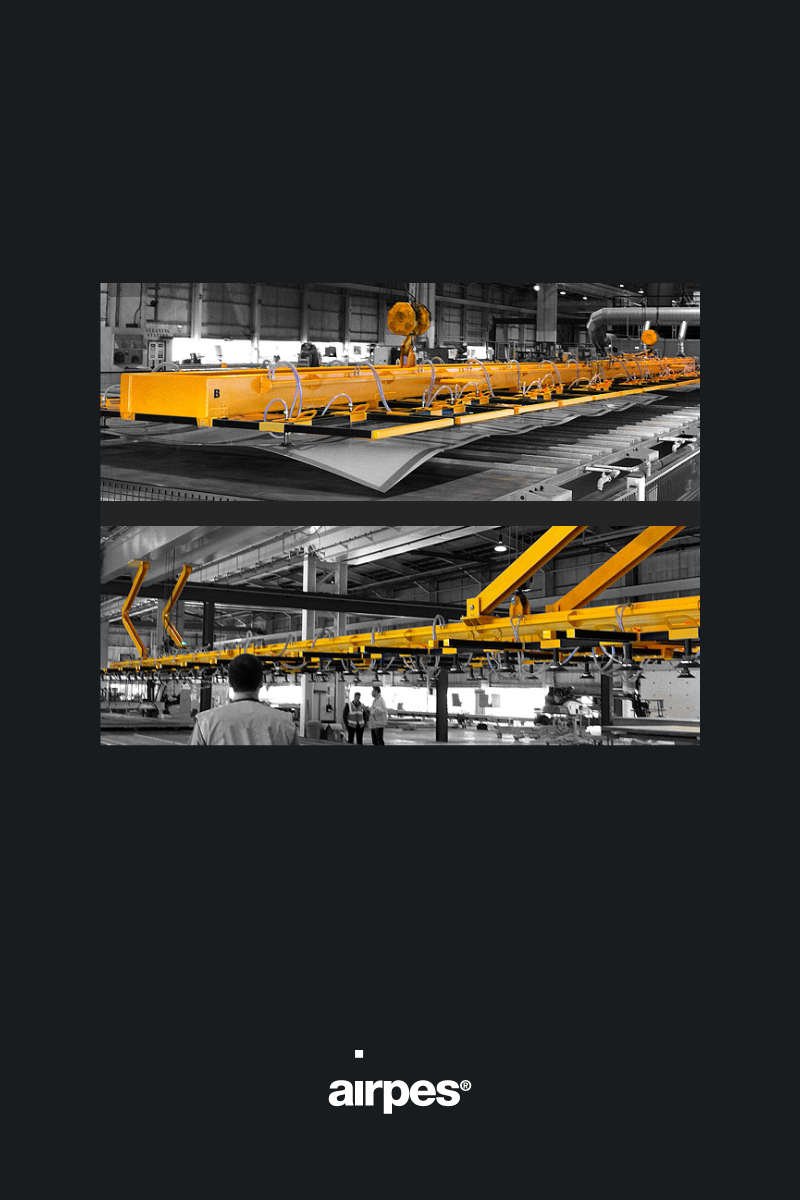

The initial situation we found in this case was a very difficult nacelle’s handling during manufacturing process that needed to be safe and efficient.

Need to solve

This rotator required a safe rotation of components to improve the operation and guard the well been of workers.

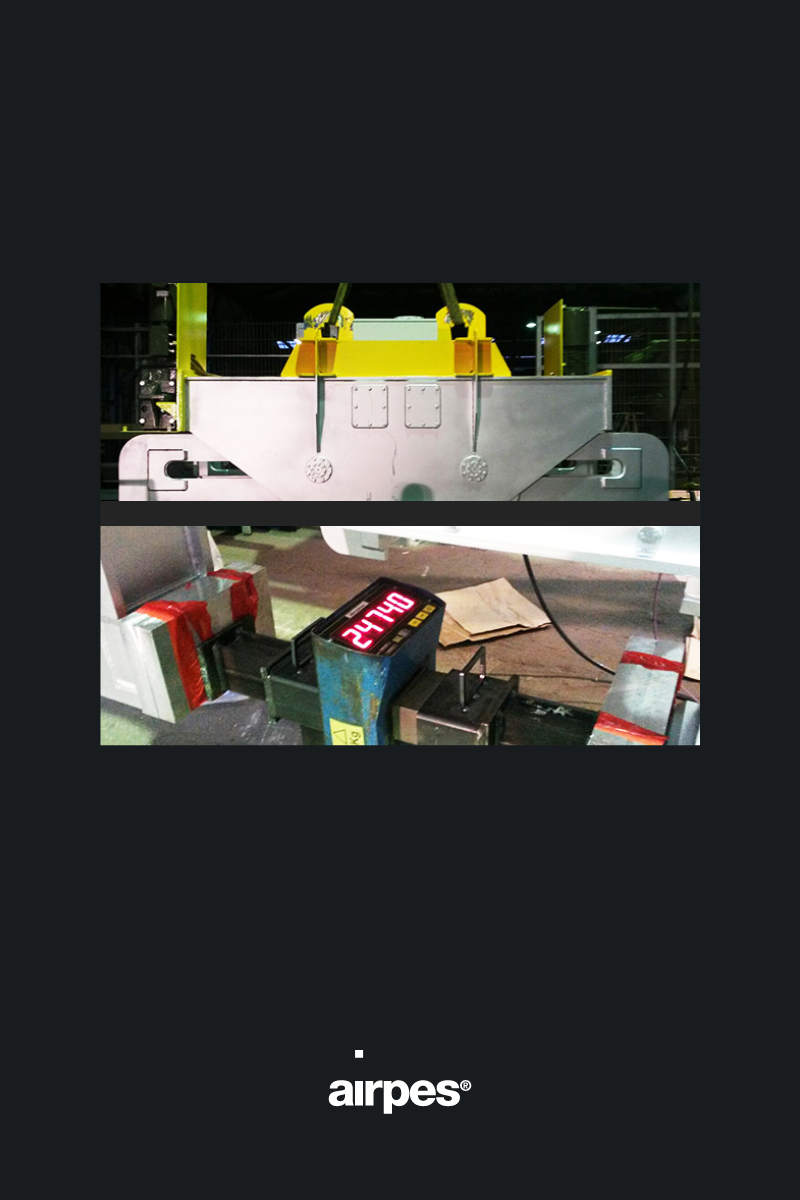

Airpes designed, manufactured and installed a rotator up to 21.5t in conformance with all OSHA and UL standards.

The rotator we delivered also included a system to deliver and handle oversized components.

- Process efficiency increased more than 50%.

- Process now under safety regulation requirements.

OUR on demand solutions

Airpes Solutions

LATEST POSTS ON THE BLOG

Discover our brand new developments, events, get posted of our activity.

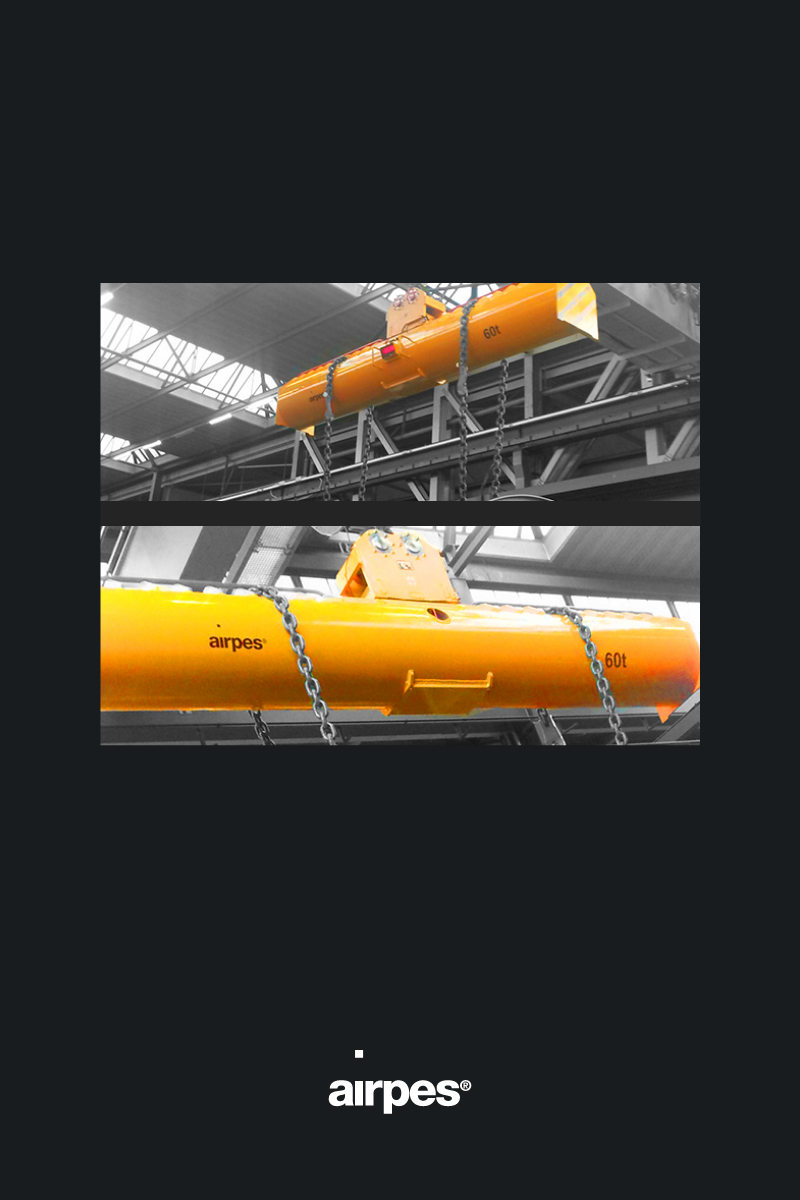

- Boost your container handling with hydraulic lifting spreader beamsDiscover how our hydraulic lifting spreader beam transforms container handling operations. Adaptable to 20", 30", and 40" containers,...

- Types of crane hooks for liftingChoosing the right crane hook ensures safe and efficient lifting operations. Discover the different types, their specific applications,...

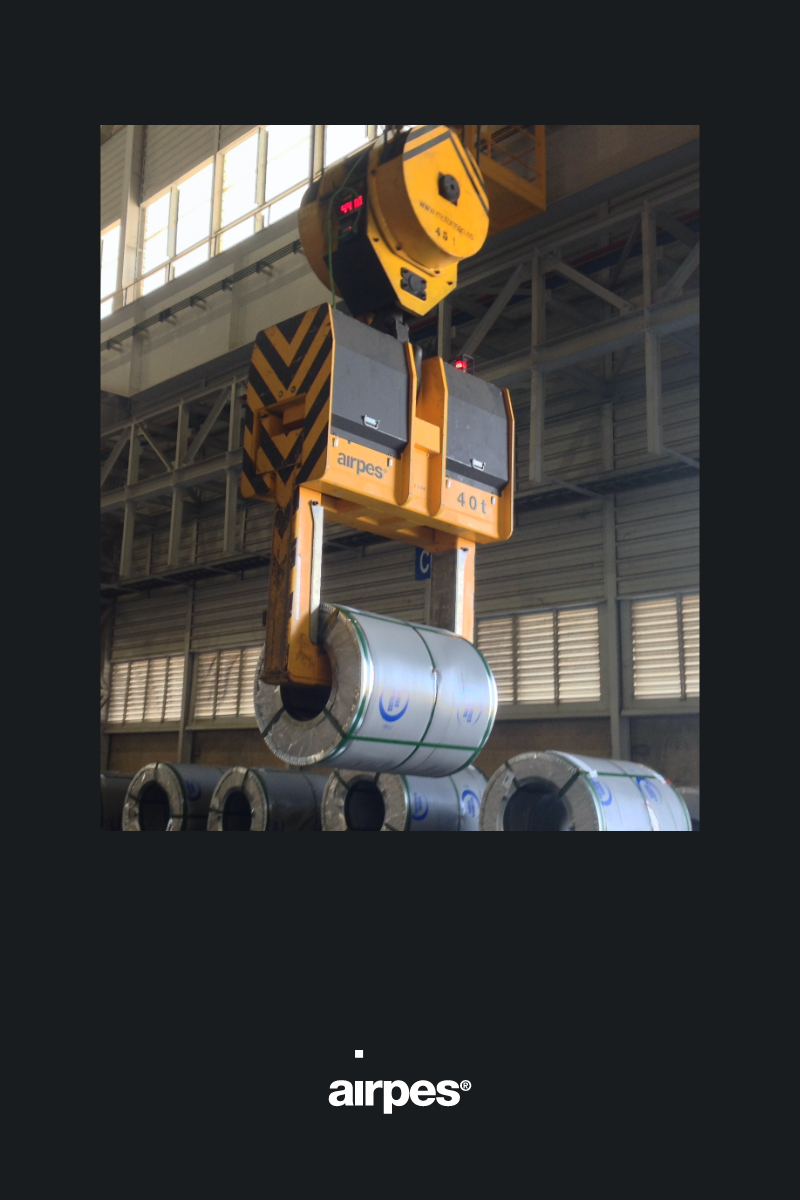

- C-Hook for lifting metal coilsLooking for a reliable way to lift heavy metal coils? This robust lifting solution, engineered by Crosby Airpes,...

- What are the five principal wind turbine parts?Wind turbines consist of five main parts: the foundation, tower, rotor and hub, nacelle, and generator. Each component...