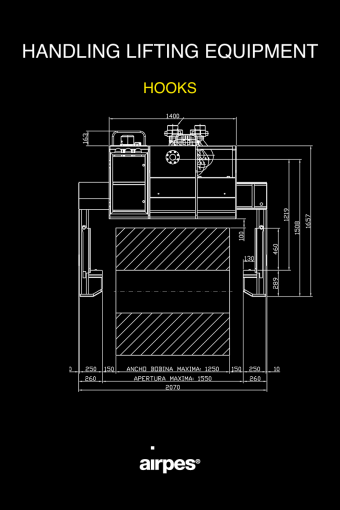

In Crosby Airpes, we specialize in designing and manufacturing high-quality hooks tailored for lifting equipment and handling projects. Our hooks are designed to fulfill the distinct specifications and needs of our clients, guaranteeing superior performance in a range of industrial uses.

Our hooks significantly improve efficiency and safety, becoming an essential element in lifting and handling tasks in any industrial environment. They are indeed vital for the smooth operation of these processes.

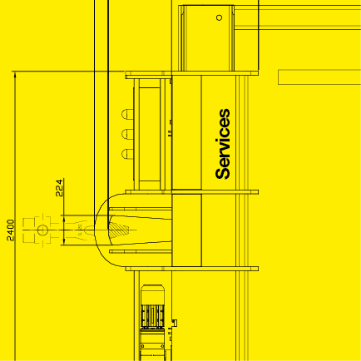

Handling projects for all industries

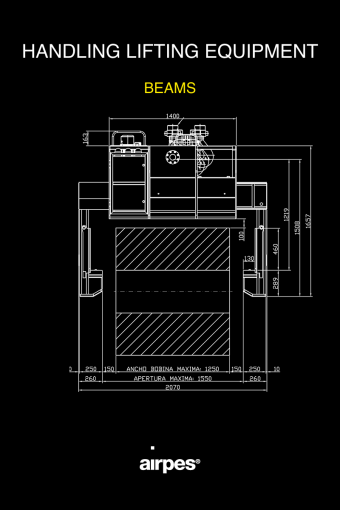

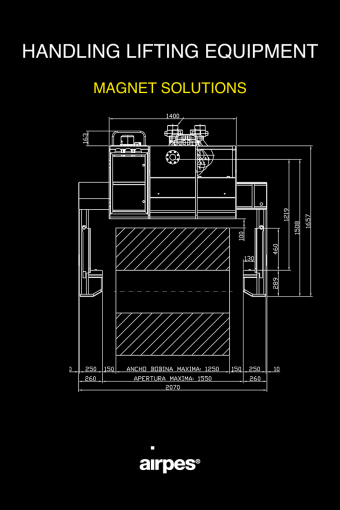

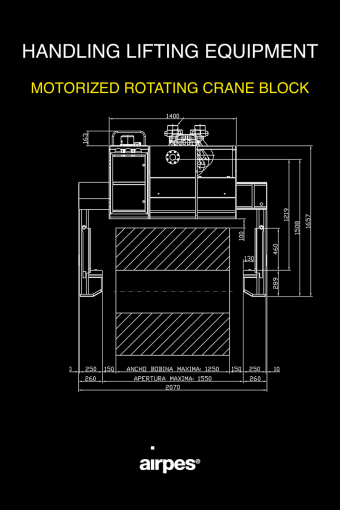

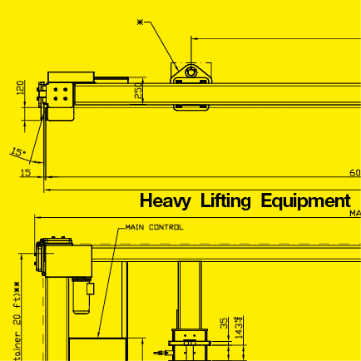

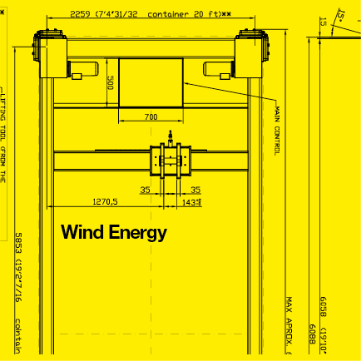

Crosby Airpes provides lifting equipment like beams, hooks, magnets, and custom solutions for various industries.

Our versatility manufacturing high-quality hooks tailored for lifting equipment and handling projects is proven by our more than twenty-five years of experience and adaptations can be made according to our clients’ needs.

Benefits of Using Crosby Airpes Handling Lifting Equipment

1. Enhanced Efficiency and Productivity

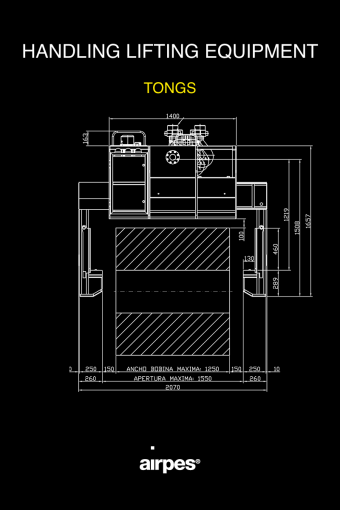

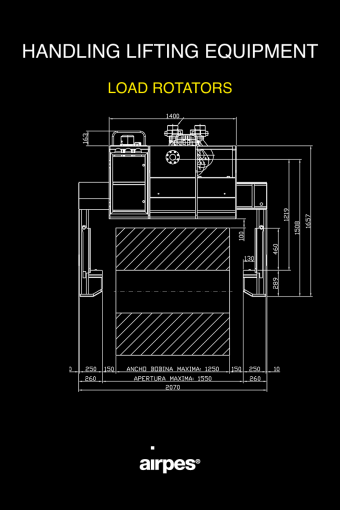

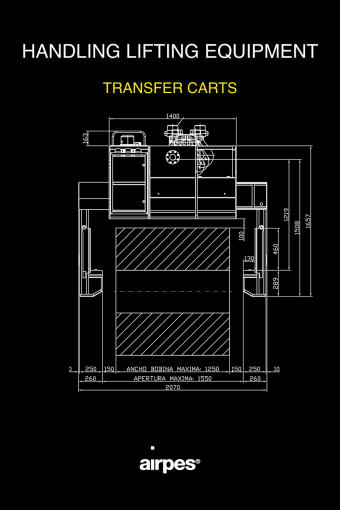

- Versatile Solutions: Crosby Airpes’ range of handling equipment is designed to cater to various industrial applications, enhancing workflow efficiency.

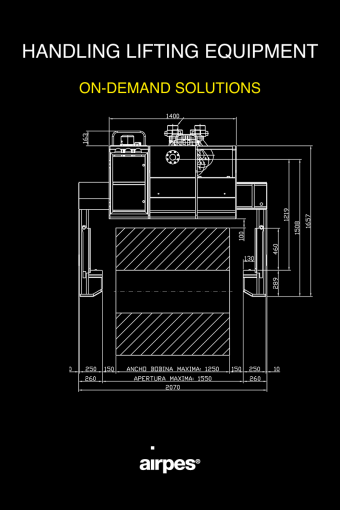

- Custom Solutions: The ability to design on-demand solutions means that specific lifting challenges can be met with tailored equipment, minimizing downtime and improving productivity.

2. Quality and Durability

By Using high-quality materials we ensure that the equipment can withstand heavy loads and harsh working conditions.

We incorporate the latest technology and design for our materials to be both reliable and efficiend, leading to a longer service life for our products.

3. Safety and Compliance

- Certified Equipment: All handling lifting equipment from Crosby Airpes meets international safety standards, ensuring safe operation in various environments.

- Enhanced Safety Features: Features like load monitoring and advanced safety mechanisms reduce the risk of accidents, protecting both workers and equipment.

Types of handling projects offered by Crosby Airpes

- C-Hooks

- J-Hooks

- Lifting Magnets

- Load Rotator

- Tongs

- Transfer Carts

We are committed to providing solutions that optimize productivity and meet the specific needs of your facility.

Safety Considerations When Using Handling Lifting Equipment

Ensuring the safety of handling lifting equipment involves comprehensive operator training, regular inspections, and routine maintenance. Operators must be well-trained and regularly updated on safety protocols.

Consistent equipment checks and scheduled maintenance are crucial for early detection of wear and tear. Additionally, assessing the load’s weight and balance, and ensuring secure lifting points, helps prevent accidents during lifting operations.

Contact us today to discuss your needs and learn how our lifting equipment can help with your handling projects.

Don’t hesitate to reach out to us for more information. Let us show you how our equipment can make a difference in your projects.