Mechanical limiters are a safe and economical way to control lifting and handling equipment, providing crane overload protection and preventing excessive strain.

These devices are crucial for ensuring crane weighing overload protection and are widely used in applications like lifting equipment, rotating machinery, and vehicles such as overhead cranes, gantry cranes, and jib cranes. They serve as essential crane overload protection devices to maintain safety and prevent mechanical failures, thus extending the equipment’s lifespan.

These devices are integrated into material handling equipment to prevent crane overload, excessive lifting speed, and operational errors that could lead to accidents or damage. A crane overload limit switch and sensors detect when the load exceeds safe levels, triggering alarms to protect both equipment and personnel.

Benefits of mechanical limiters

- Safety: Torque limiters, overload sensors, and mechanical switches are crucial for crane safety, preventing crane overload conditions that could lead to damage or failure. Properly installed crane overload protection devices can ensure compliance with safety regulations for hoists and cranes.

- Compliance with Regulations: Many industries require strict adherence to safety protocols, including crane overload tests to verify equipment performance. This ensures that hoists and cranes operate within safe limits.

- Cost-Efficiency: By preventing overload damage, these devices reduce repair costs, downtime, and insurance claims, making operations more sustainable than ever.

- Equipment Longevity: Mechanical limiters ensure that components like gear reducers and manual cranes function within their rated capacity, reducing the need for frequent repairs.

- Precision and Control: In complex systems, limiters provide load limitation, ensuring that lifting operations do not exceed predetermined safety thresholds.

Limiters by Crosby Airpes: Overload Protection Devices

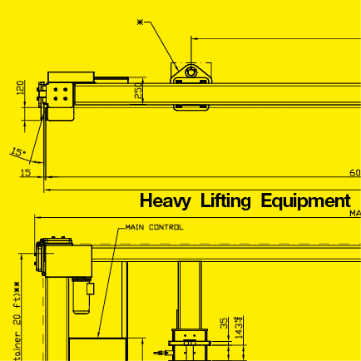

We offer two types of mechanical limiters tailored to different needs:

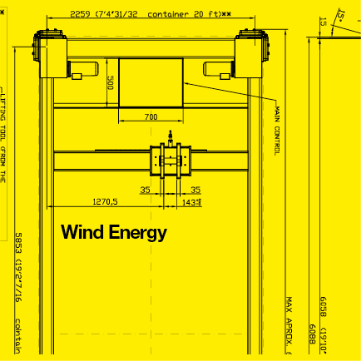

1. ALM M-100: This mechanical limiter is perfect for extreme environments, providing reliable crane overload protection at temperatures from -30 to +60 °C, with load capacities ranging from 250 kg to 8,500 kg. A crane overload alarm detects issues before they become critical.

2. ALM M-100EX: For hazardous environments, this model provides automatic crane overload protection for cranes, elevators, and hoists. It’s equipped with a crane overload limit switch to ensure safe lifting in areas where precision is critical. The crane overload alarm system notifies operators when the load approaches unsafe levels.

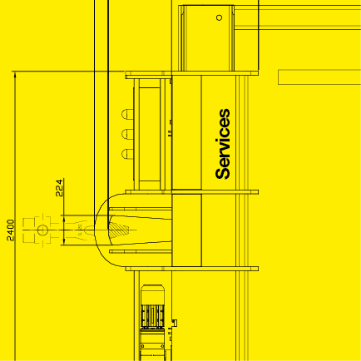

Additional Features and Services

Discover more about our crane overload protection devices and their capabilities. Our services include information about specific solutions for lifting equipment, ensuring compliance with safety standards. Whether you need specifications, crane overload tests, or remote monitoring, we are ready to support your needs.

Contact us for catalogs, technical assistance or to place an order, and learn more about crane safety and how our systems can protect your equipment from crane overload conditions in our blog.

FAQs

Why is a crane overload limit switch important?

A mechanical overload limiter prevents potential damage to the crane by triggering a crane overload alarm and stopping operations if the load is too heavy. Installing a crane overload protection device ensures that your equipment remains safe, reducing the risk of mechanical failures and accidents.

How do mechanical limiters provide overload protection for cranes?

Mechanical limiters are designed to monitor load limits in real-time, ensuring that overload protection for hoists and cranes is maintained. These devices, including the crane overload protection systems we offer, detect when the load exceeds safe levels and can activate a crane overload alarm. Note that overweight can come also for lifting too fast a weight that is near the limits of the system. A mechanical limiter will help you also in this case.

How can I perform a crane overload test to ensure safety compliance?

To conduct a crane overload test, you need to load the crane to its maximum rated capacity and verify that the crane overload protection devices and limit switches are functioning correctly. This test ensures that the crane overload systems will activate when necessary, preventing overloading. Crosby Airpes can help you perform these tests thanks to our test bench for cranes in our facility in Barcelona.