Airpes is your supplier of Monitoring and Overload Protection Systems.

Monitoring and overload protection systems are essential components in industrial operations that help ensure the safe and efficient use of machinery and equipment.

Here’s an overview of what these systems are and how they function:

by incorporating such systems, businesses can maintain a high level of operational integrity, safeguard their workforce, and optimize their processes, all of which contribute to a more stable and profitable operation.

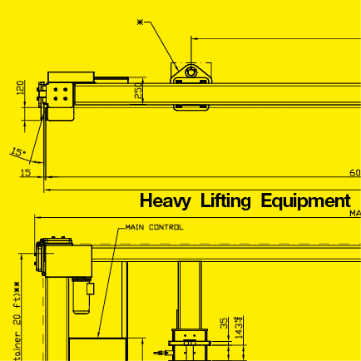

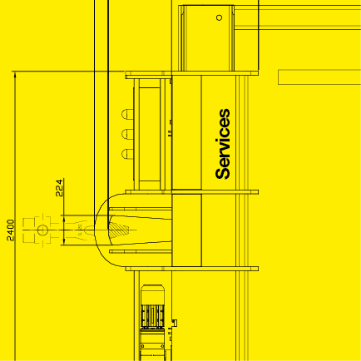

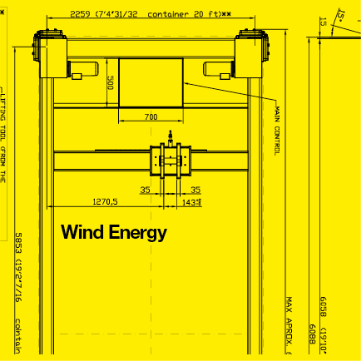

Every Crosby Airpes system is meticulously designed to answer your needs. Our monitoring systems are used to continuously observe the performance and status of equipment during operation.

Benefits of all types of monitoring and overload protection systems

● Improved Efficiency

Systems that monitor and control the load can optimize the performance of machinery, ensuring that operations are carried out efficiently without risking overloads.

● Enhanced Safety

These systems provide essential safeguards that prevent accidents by ensuring equipment operates within safe limits. They help avoid situations that could lead to injuries or fatalities, such as equipment overload or failures.

● Prevention of Equipment Damage

By monitoring operational parameters and shutting down machinery when it exceeds those limits, these systems prevent the costly breakdowns and repairs that can occur from overloading equipment.

● Cost Savings

The ability to prevent equipment failure and reduce downtime leads to significant cost savings. Not only are repair and replacement costs minimized, but the avoidance of accidents also reduces potential legal and insurance expenses.

● Data Collection for Predictive Maintenance

Modern systems can collect and analyze data that can be used for predictive maintenance. This allows maintenance to be scheduled at convenient times and before equipment fails, thereby avoiding unexpected downtime.

● Regulatory Compliance

Many industries have strict regulatory requirements regarding equipment safety. Monitoring and protection systems ensure compliance with these regulations, helping businesses avoid penalties and legal issues.

These systems are integral to modern industrial operations, where they contribute to the reliability, safety, and efficiency of processes across various sectors such as manufacturing, construction, and transportation. Let’s talk about principal types.

Principal types of monitoring

Load cells are vital in monitoring the force exerted on equipment like cranes and hoists, ensuring they operate within safe load limits to prevent overloading and potential hazards. Similarly, limit switches automatically halt machinery at predetermined safe limits to avoid mechanical overreach and accidents. Torque limiters protect machinery by disengaging the load when torque exceeds set limits, preserving equipment integrity and safety. Electronic monitoring systems leverage sensors and analytics to monitor equipment parameters like temperature and vibration, providing real-time alerts to prevent overload and facilitate maintenance.

Circuit breakers and fuses are critical in electrical systems, cutting off power when currents exceed safe levels to prevent potential damage and hazards. Pressure relief valves are essential in fluid systems, releasing excess pressure to prevent system failures like bursts or ruptures. Thermal protectors in motors and generators prevent overheating, ensuring operational safety and preventing damage.

Benefits of Crosby Airpes monitoring systems

Crosby Airpes offers a variety of monitoring and overload protection systems designed to ensure safe and efficient operations in industrial environments. Their offerings include load cells, which measure and provide feedback on forces exerted on machinery to prevent overloads. Additionally, electronic limiters control and monitor the overload protection of machinery. And, finally, the display controls the scales and gives us information, becoming a very important element in your job. Discover what display fits more your business needs.

Look how Eagle makes it and achieve the goal:

Advantages of our systems include

● Enhanced Safety: prevents accidents by ensuring machinery operates within safe operational limits.

● Improved Accuracy: provides precise measurements critical for safe and efficient equipment operations.

● Cost Efficiency: reduces potential costly damages and downtime by preventing overloads.

● Versatility: suitable for various industrial applications, ensuring broad compatibility and application.

Crosby Airpes help you with your specific type of monitoring and overload protection systems.

In addition to the aforementioned services, we can offer you on-demand solutions tailored to your specific industry and needs. These customized solutions are designed to seamlessly integrate into your existing processes, ensuring efficient and effective enhancements to your operations.