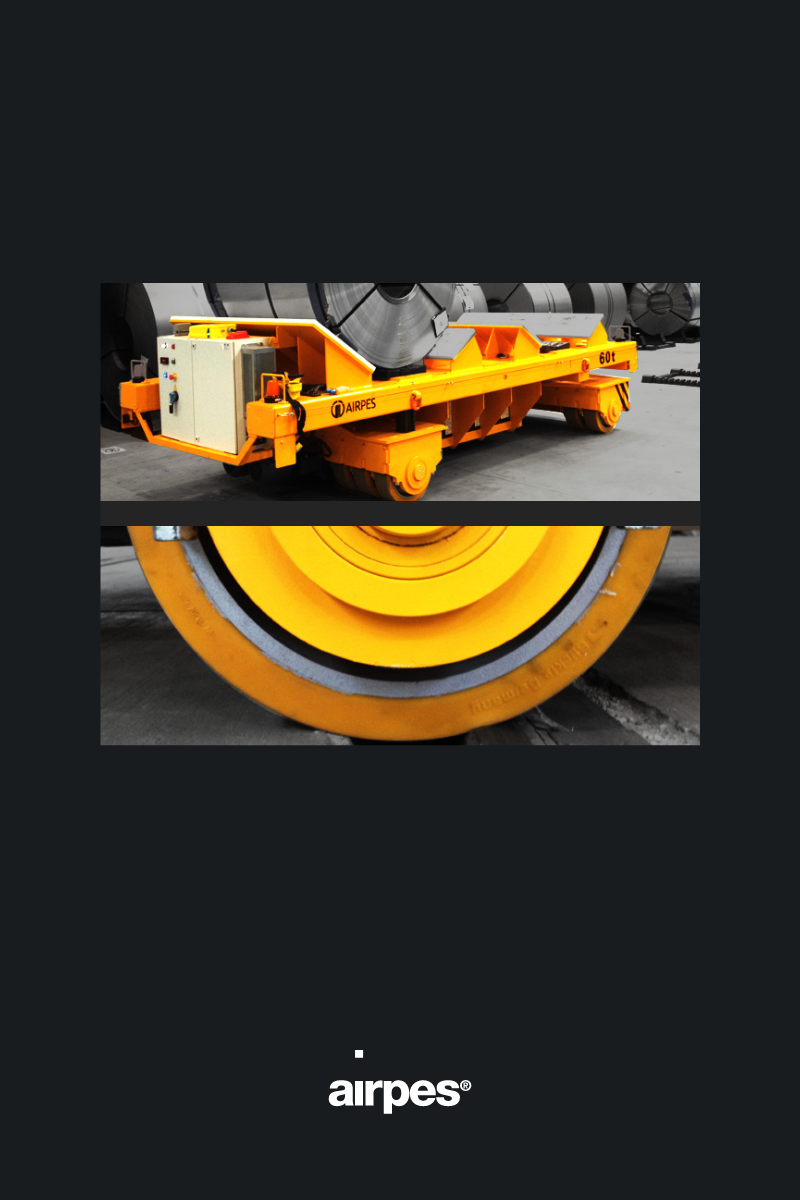

Handling & weighing equipment for Bahru Stainless

Bahru Stainless is part of the Acerinox Group and a leader in the Annealing and pickling lines for hot and cold rolled coils.

Involved in a large project since 2008, it has at last been build an integrated stainless steel factory with a melting capacity of 1 million Mt and a cold rolling capacity of 600,000 Mt.

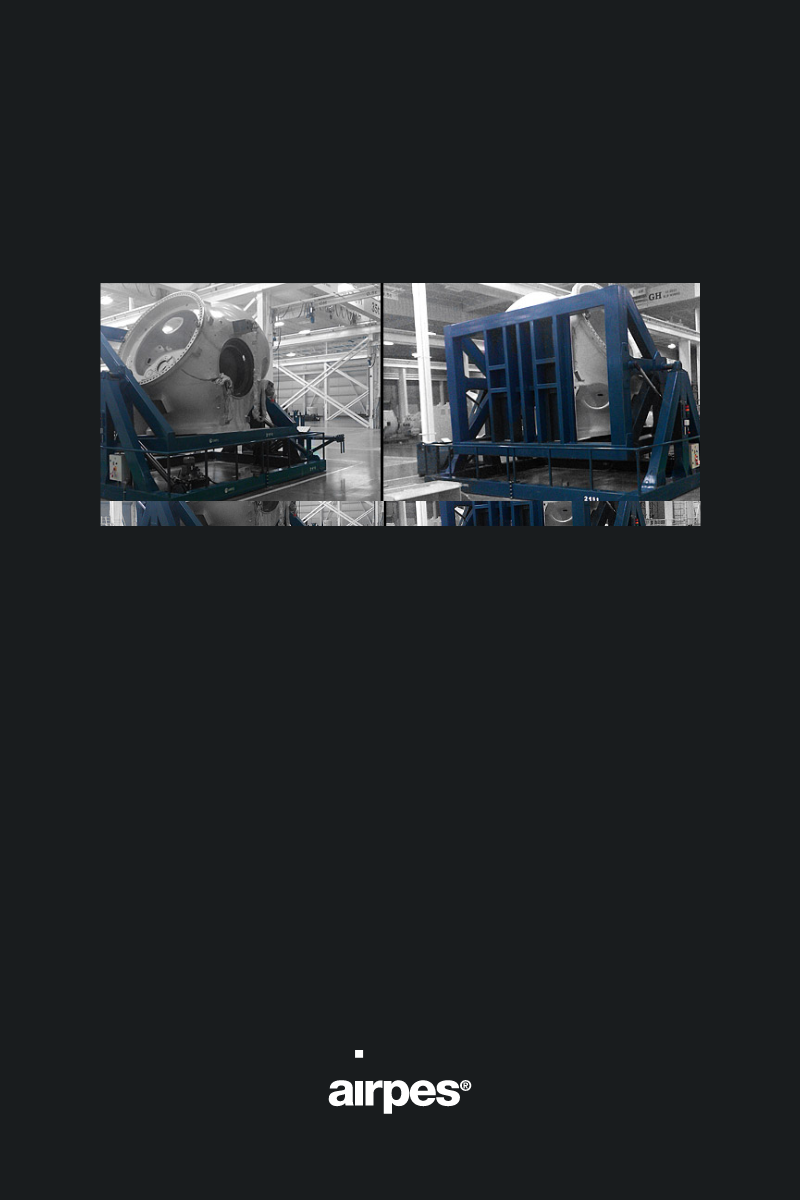

Regarding this increase in the production, Bahru Stainless has demanded some handling equipment.

Airpes, since its beginning, has been supplying handling and weighing equipment to the Acerinox Group.

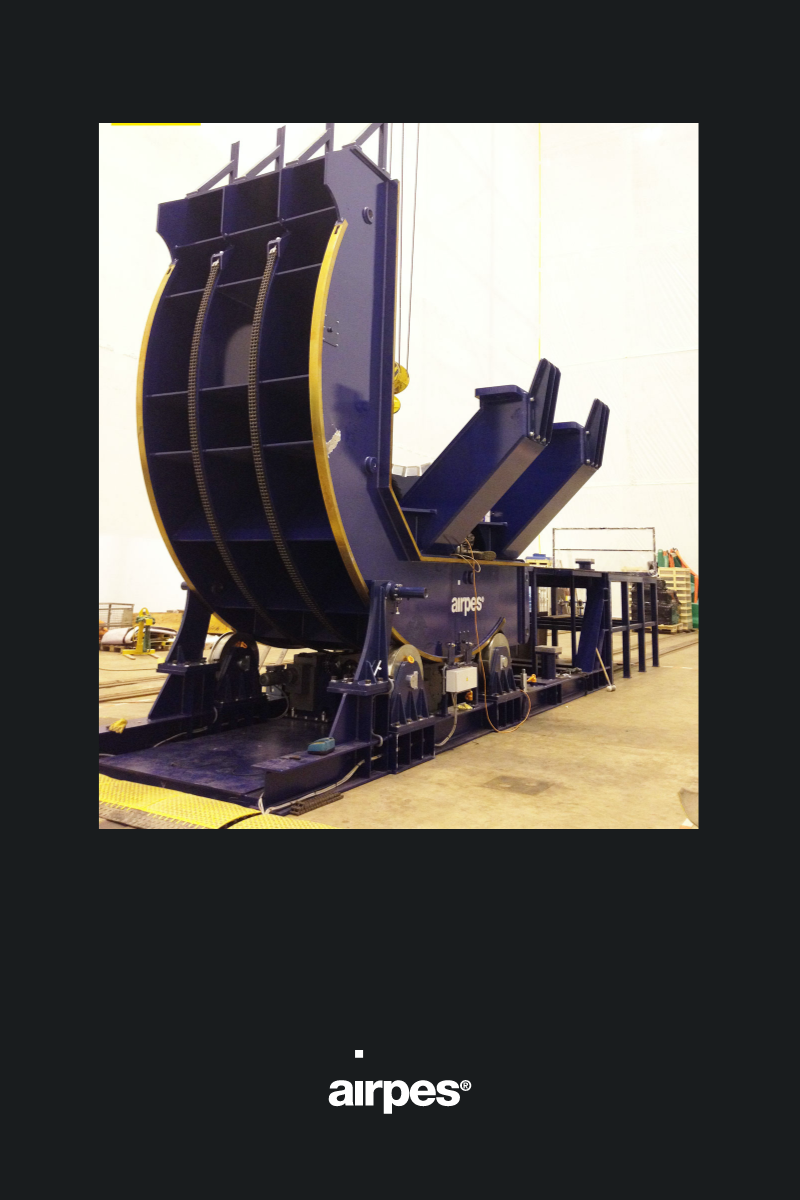

For this particularly project we supplied:

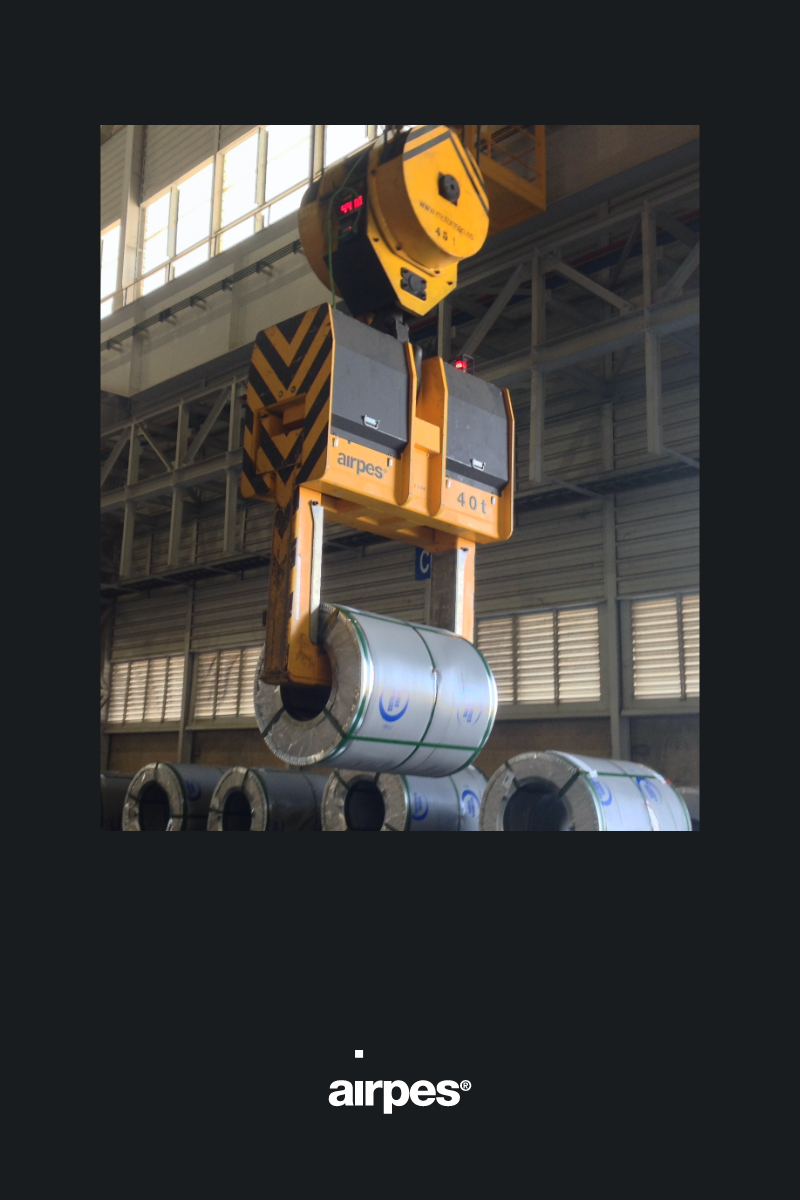

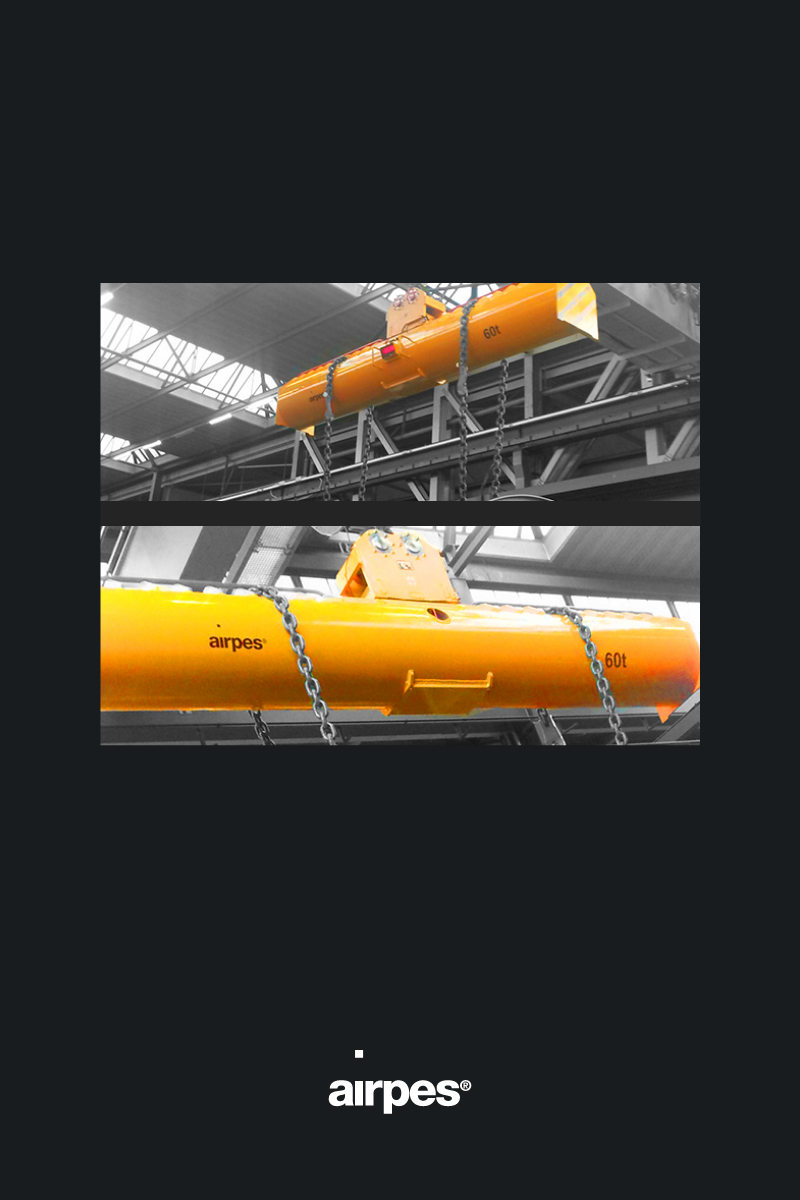

- 4 Coil Tongs 40t SWL

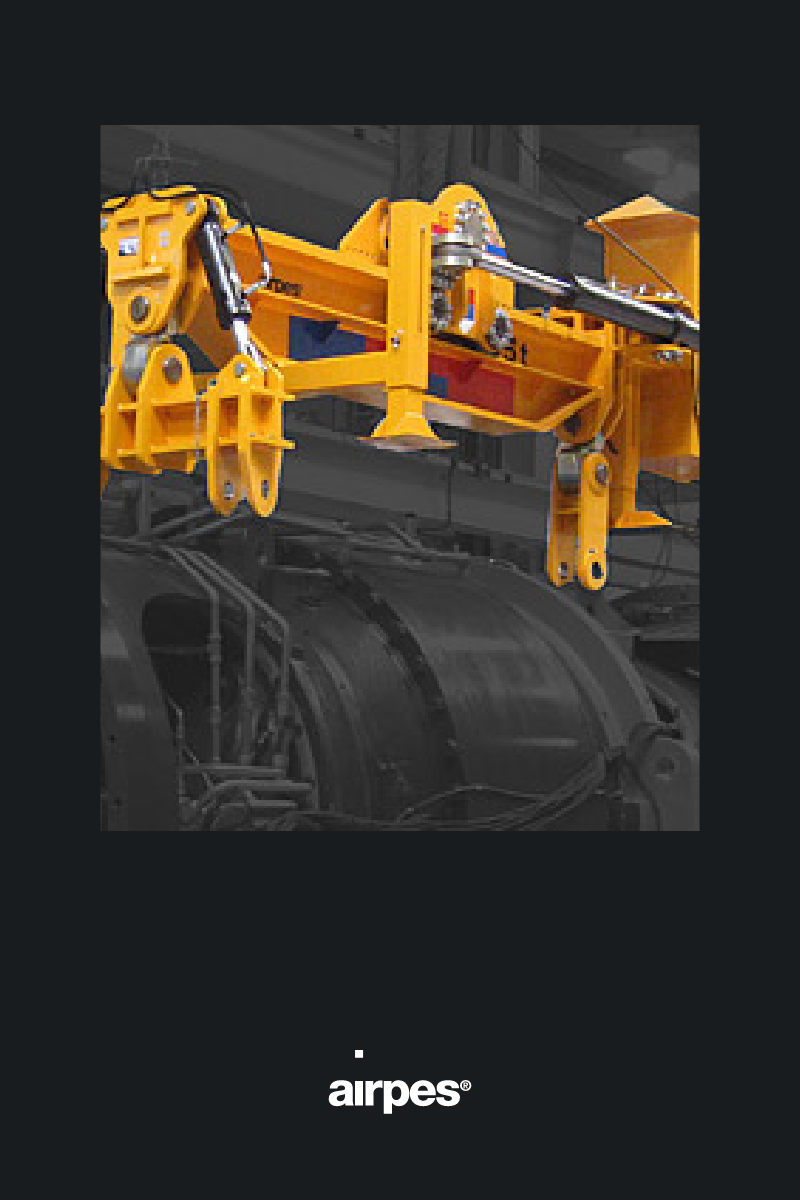

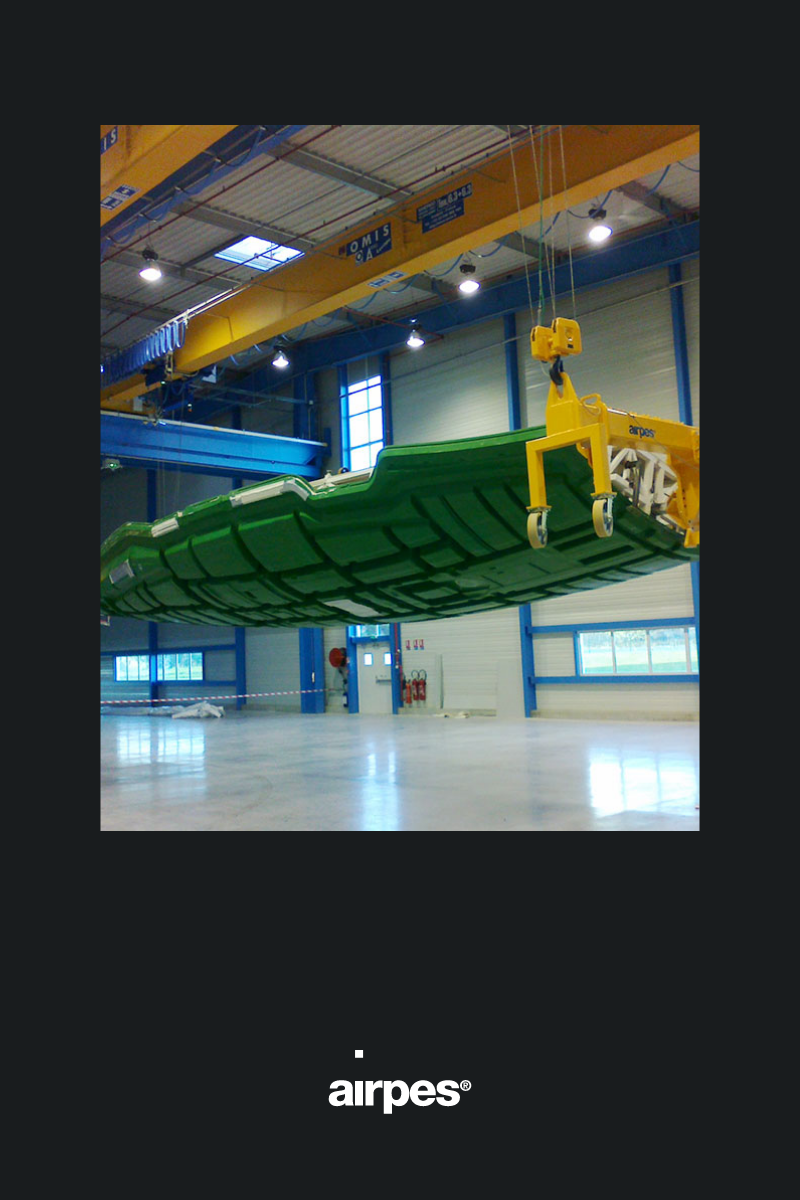

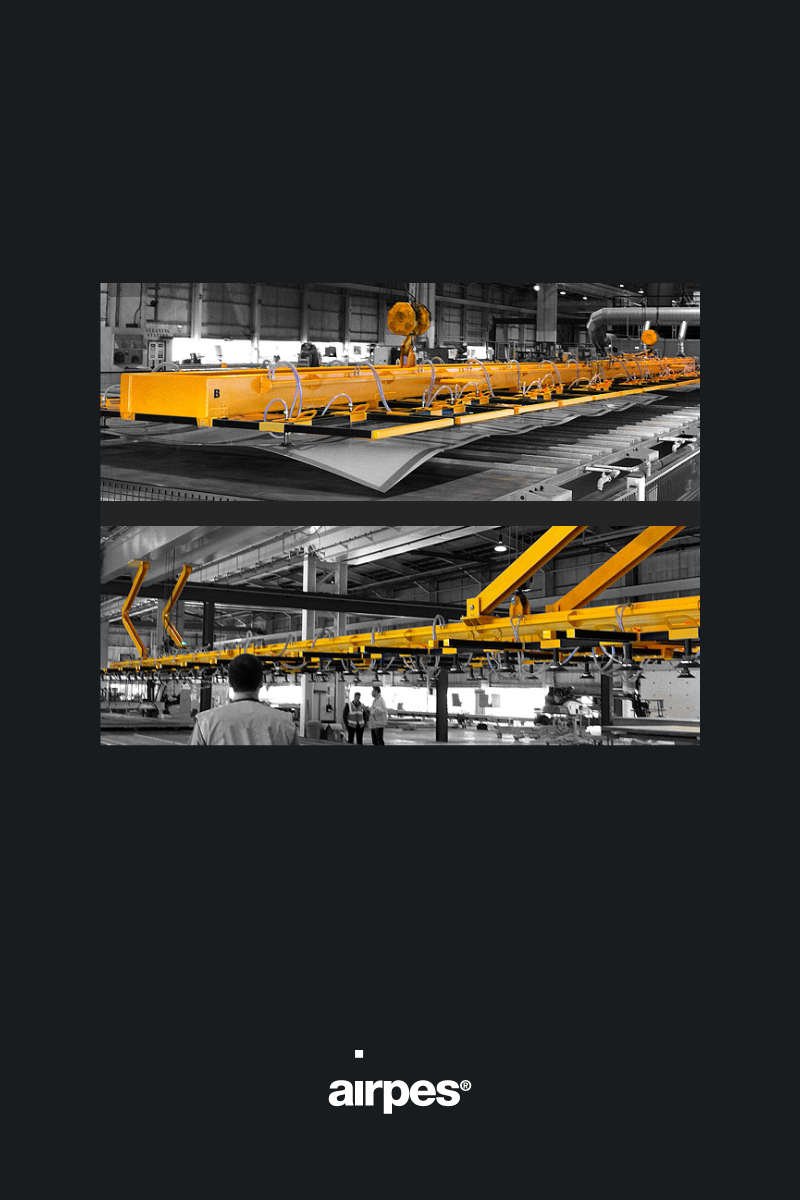

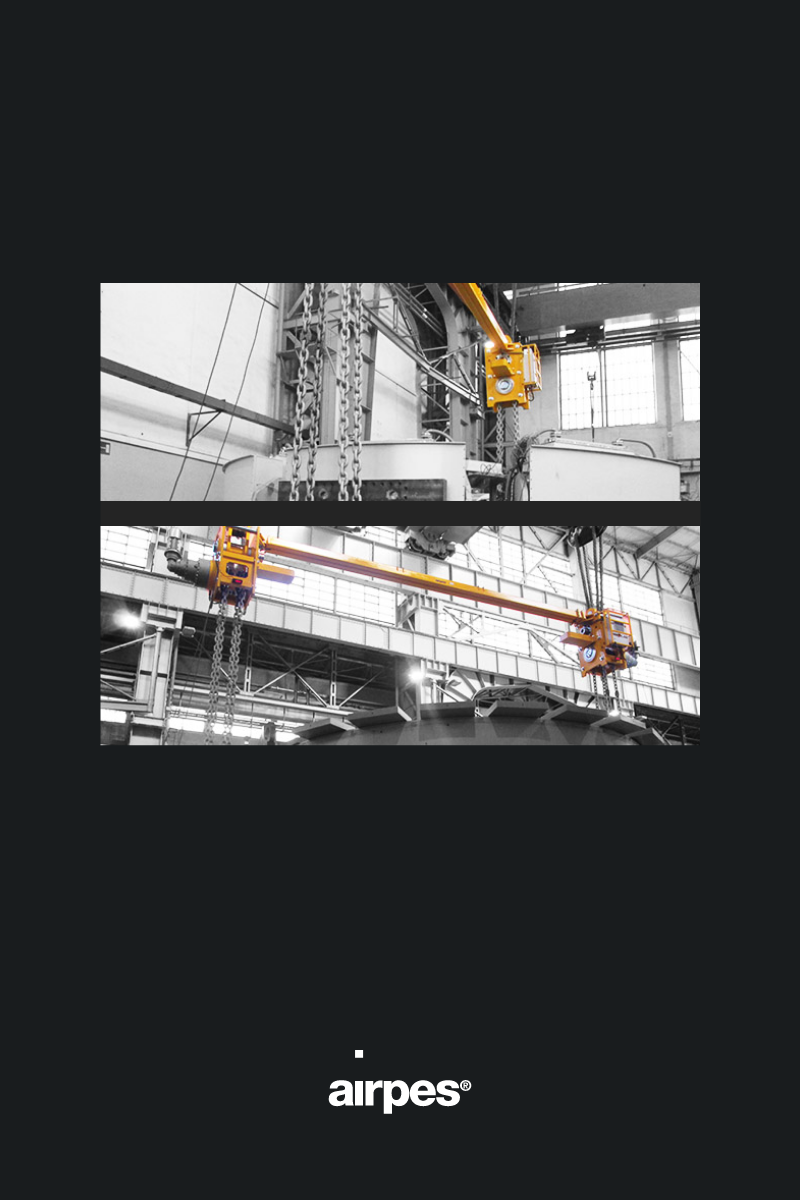

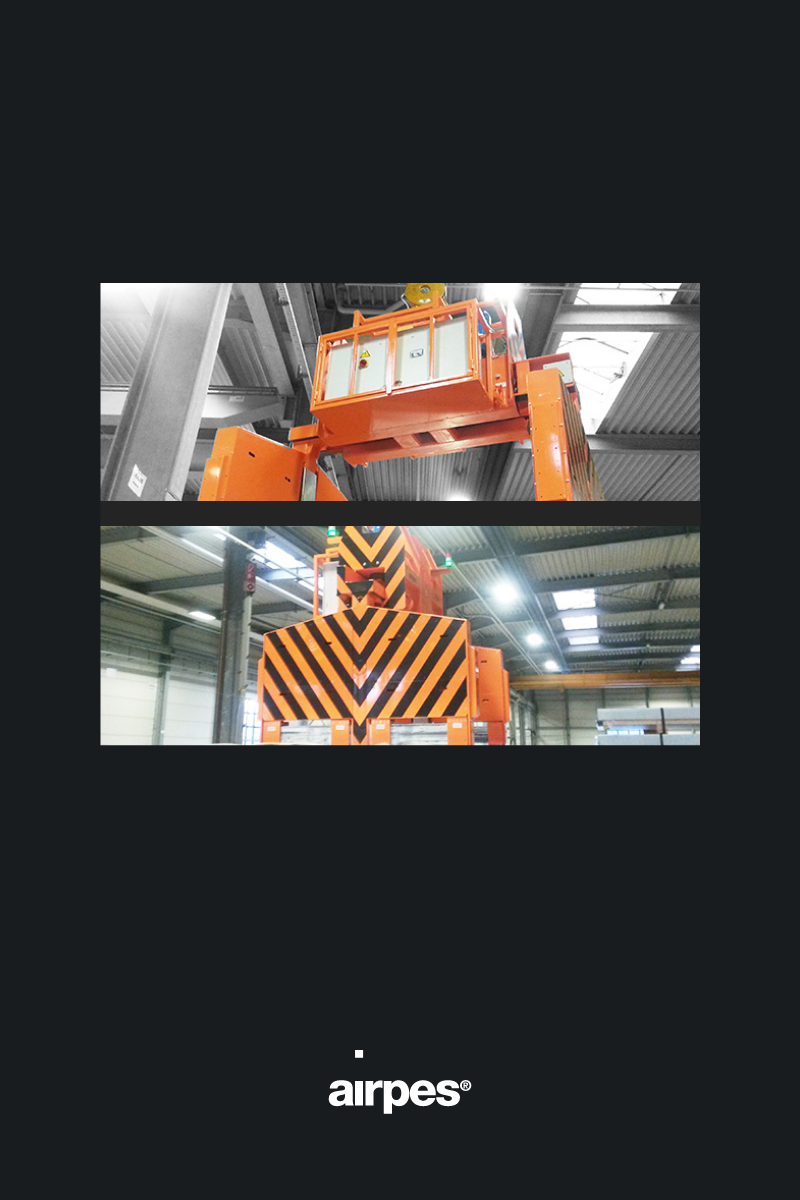

- 2 Sheet metal tongs with motorized tong arms which are adjustable in longitudinal and transverse direction.

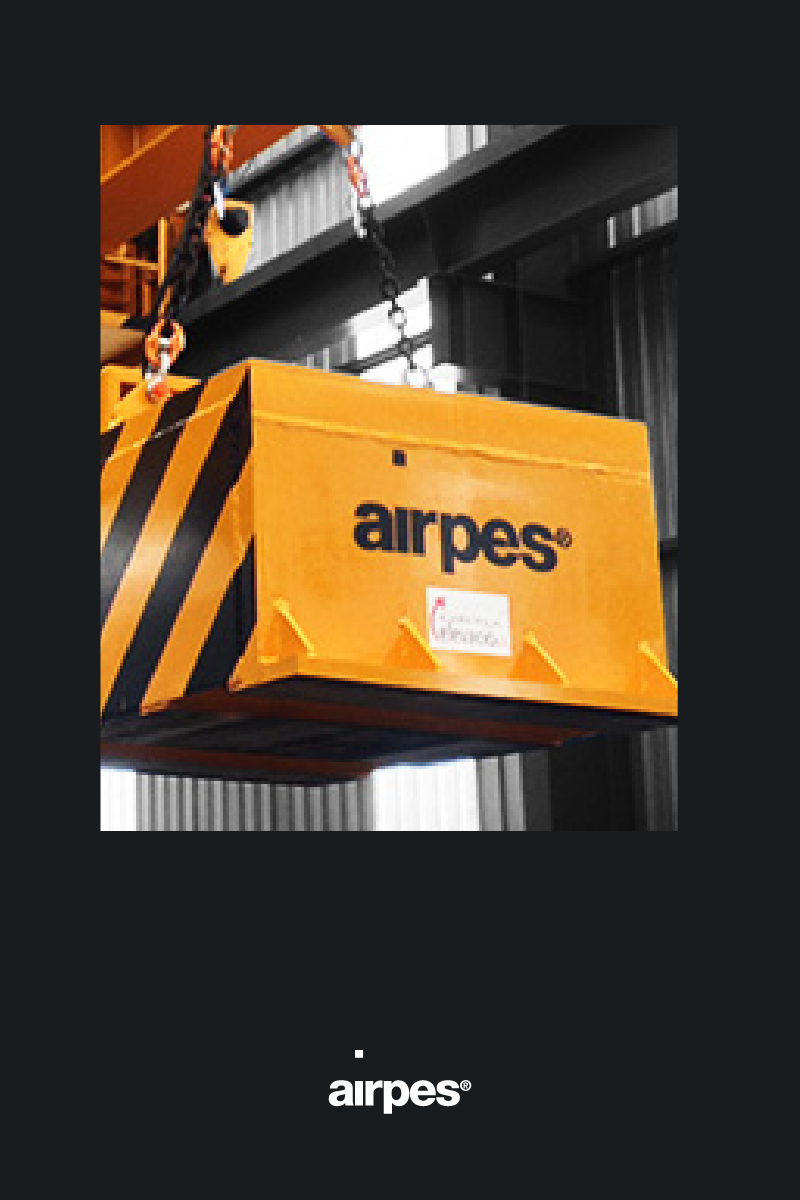

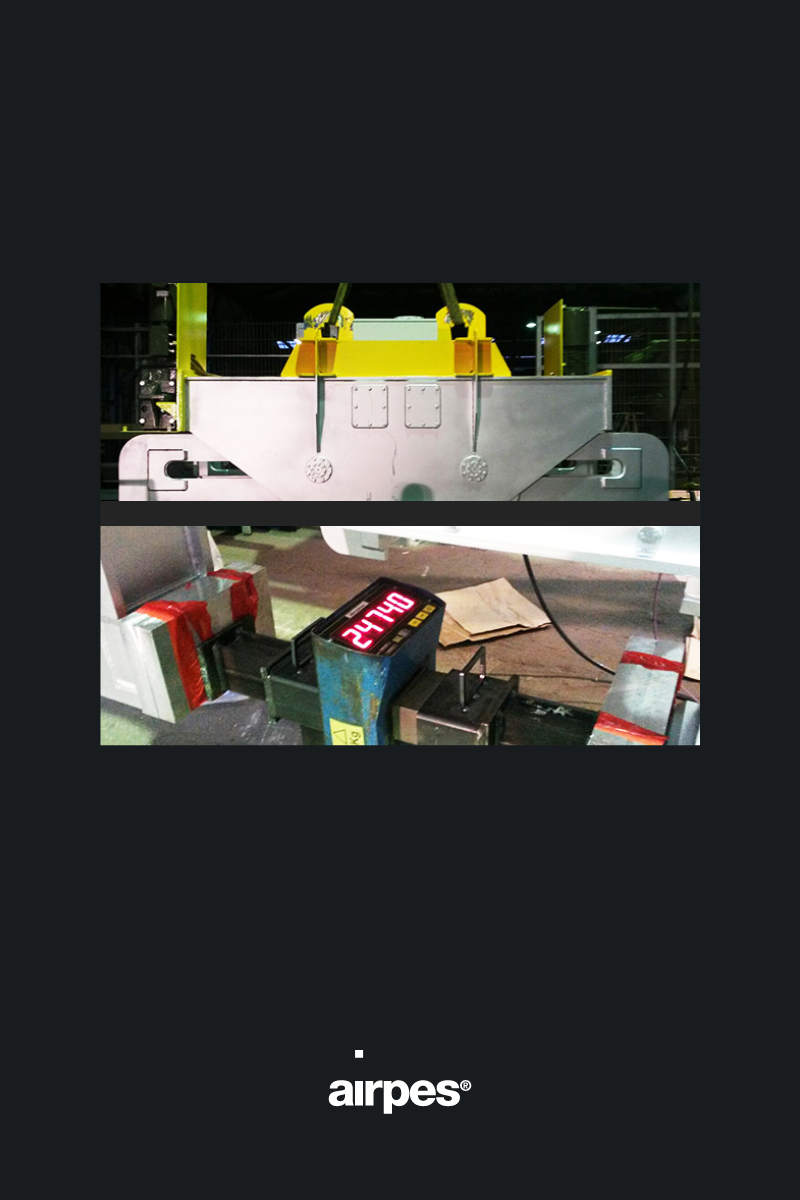

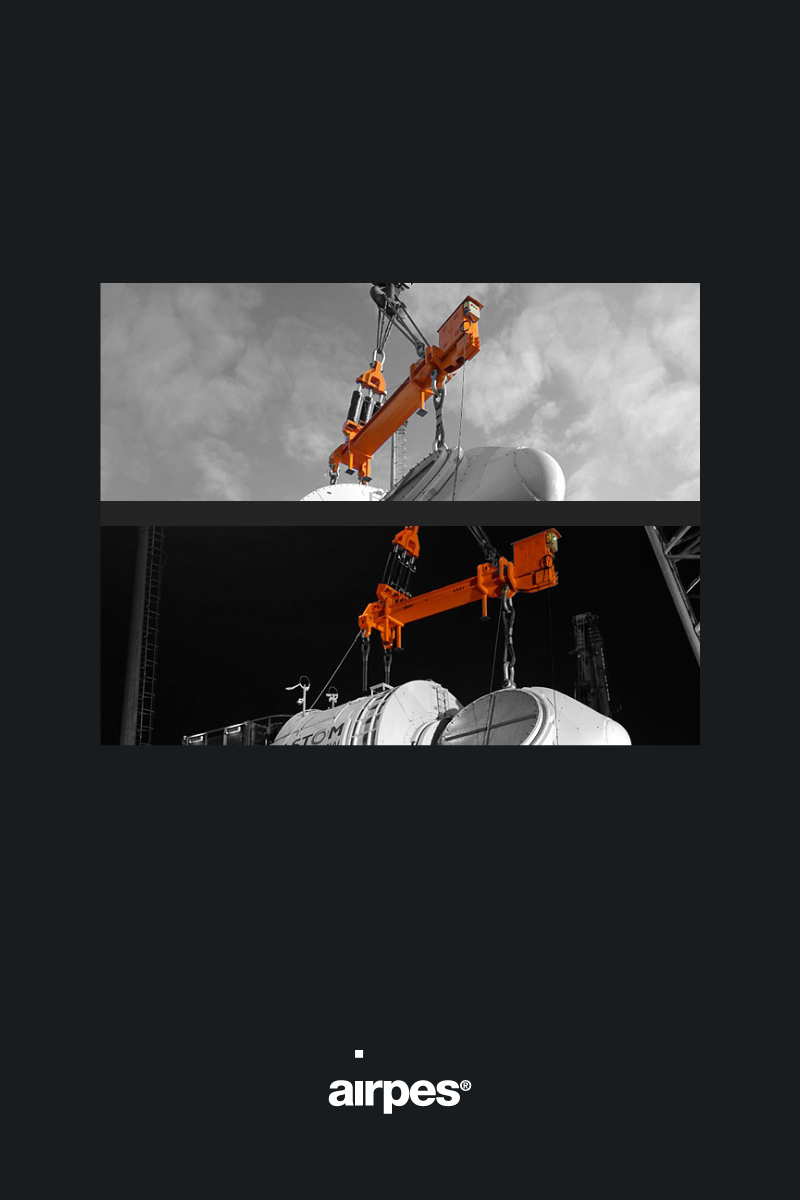

- 2 Weighing and motorized hook blocks.

Airpes’ technical team visited the Bahru Stainless factory in Malaysia to verify and validate the machines provided.

- The equipment works safe, according to the standars of quality and service that Bahru Stainless expected.

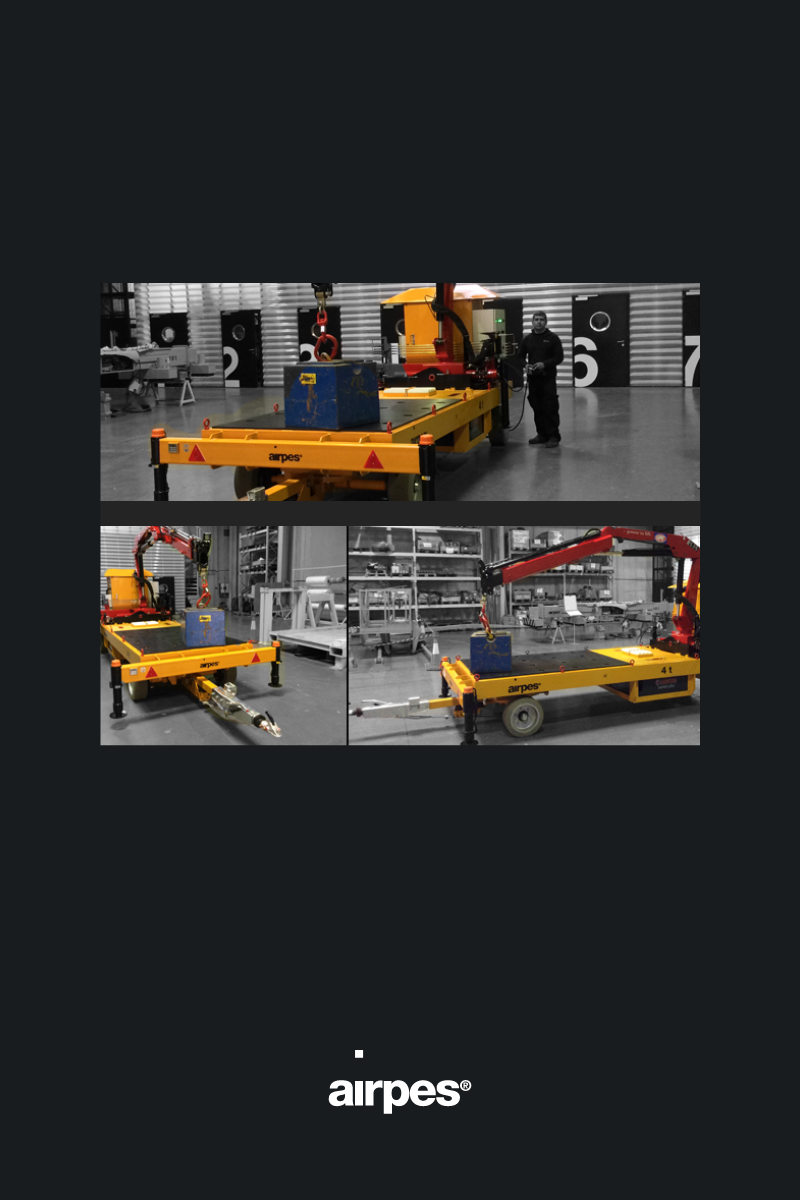

OUR on demand solutions

Airpes Solutions

LATEST POSTS ON THE BLOG

Discover our brand new developments, events, get posted of our activity.

- What is a lifting electromagnet system and how does it work?Lifting electromagnet systems offer a safe, efficient, and cost-effective solution for handling steel plates, beams, and other ferrous...

- Why crane load block is an essential tool in lifting operationsLearn how crane load blocks improve lifting operations by optimizing weight distribution, reducing strain, and ensuring safety. Discover...

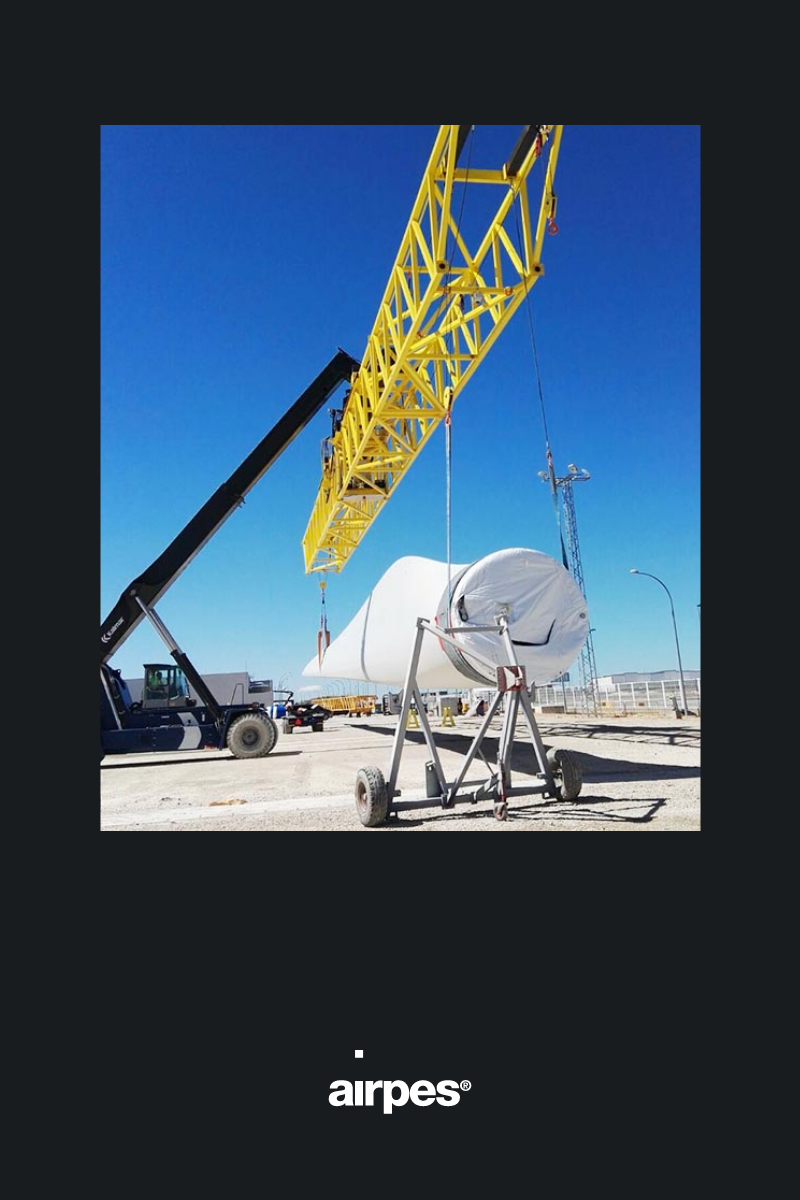

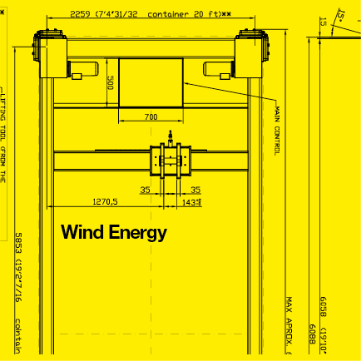

- Wind turbine blades: design, curiosities and moreHave you ever wondered how a wind turbine tower can support so much weight? Here all the details...

- Monorail Crane: pros, cons, and best uses explainedExplore the advantages and limitations of monorail cranes, and learn how to maximize their use for more efficient...