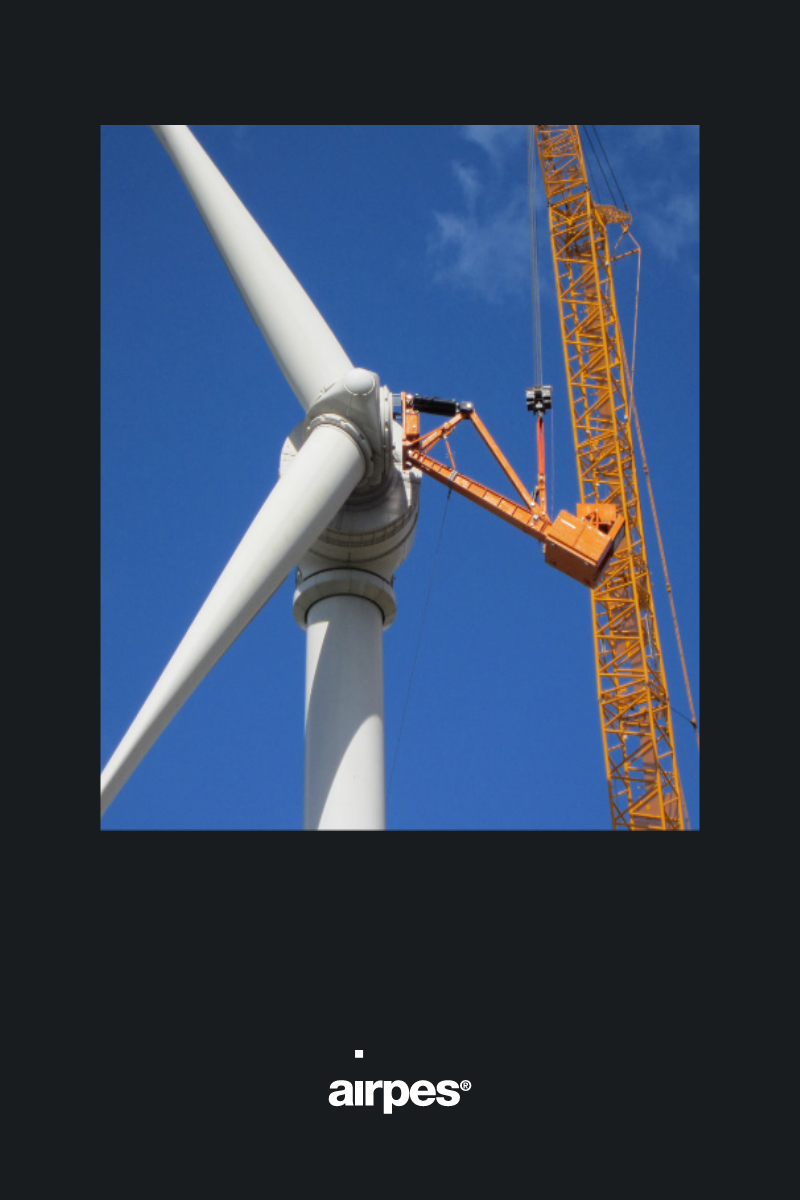

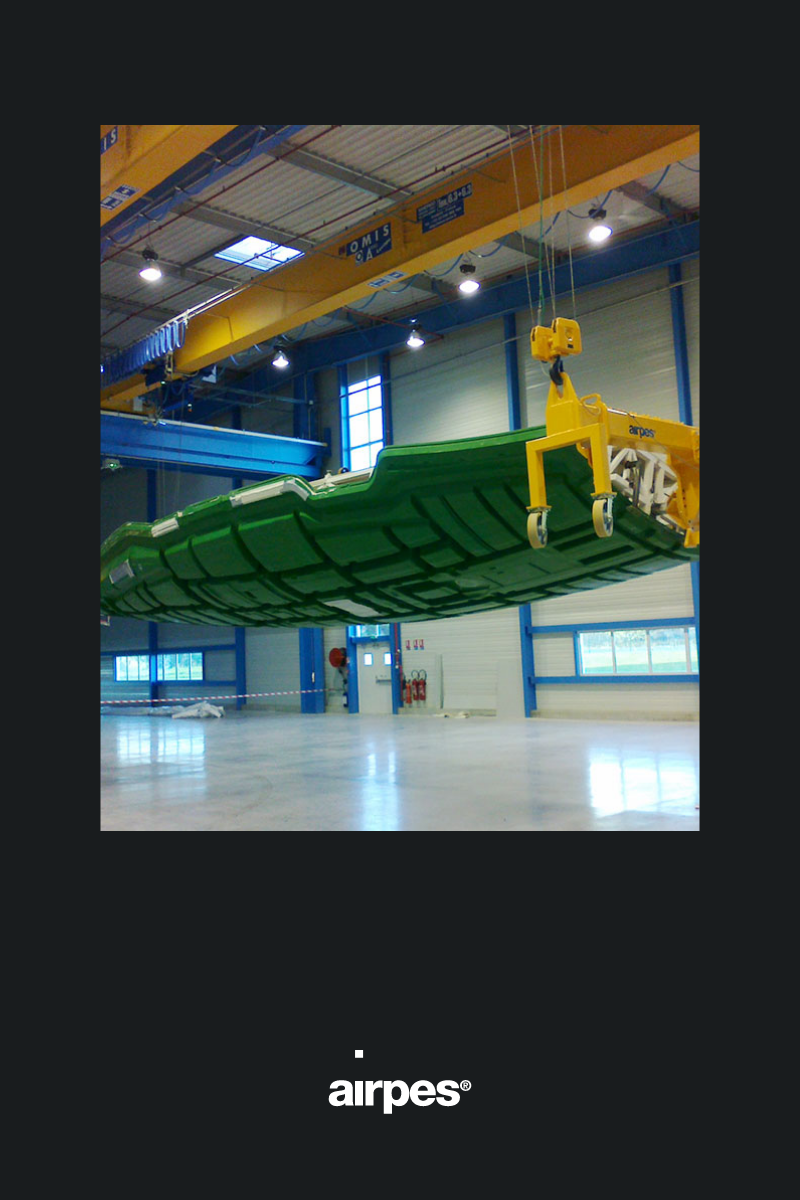

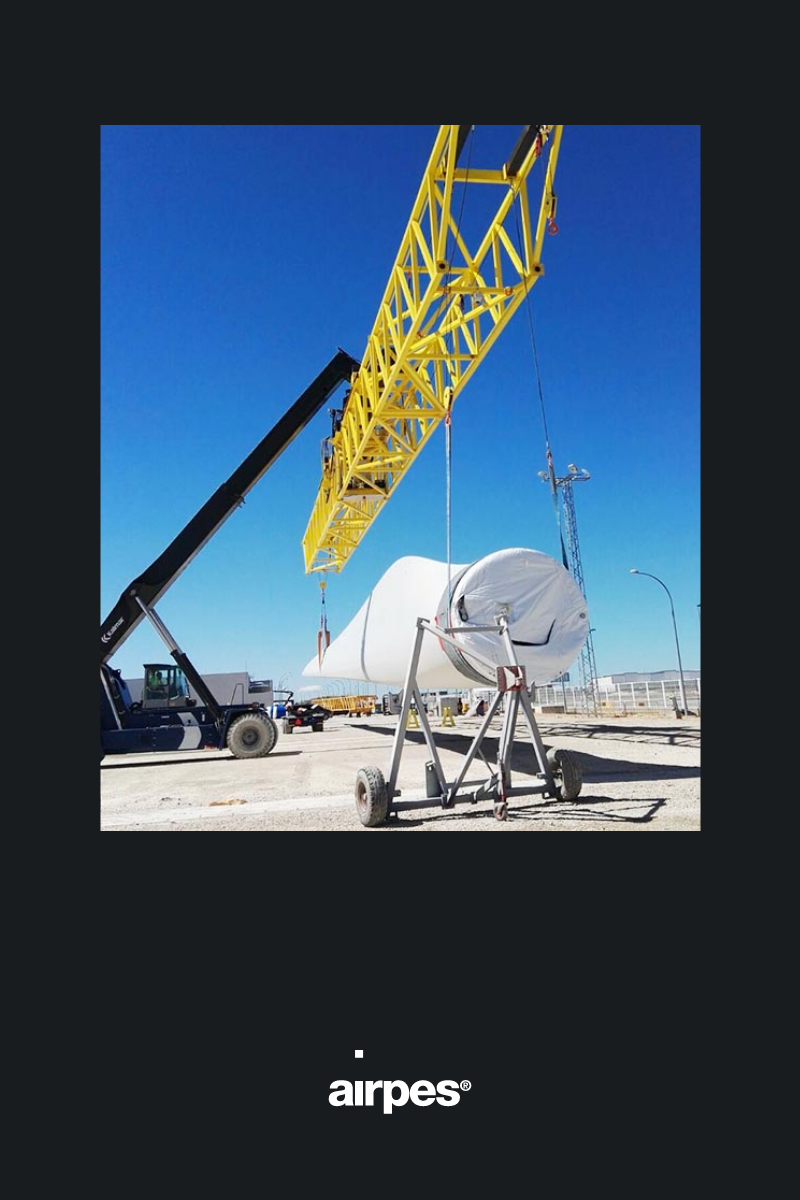

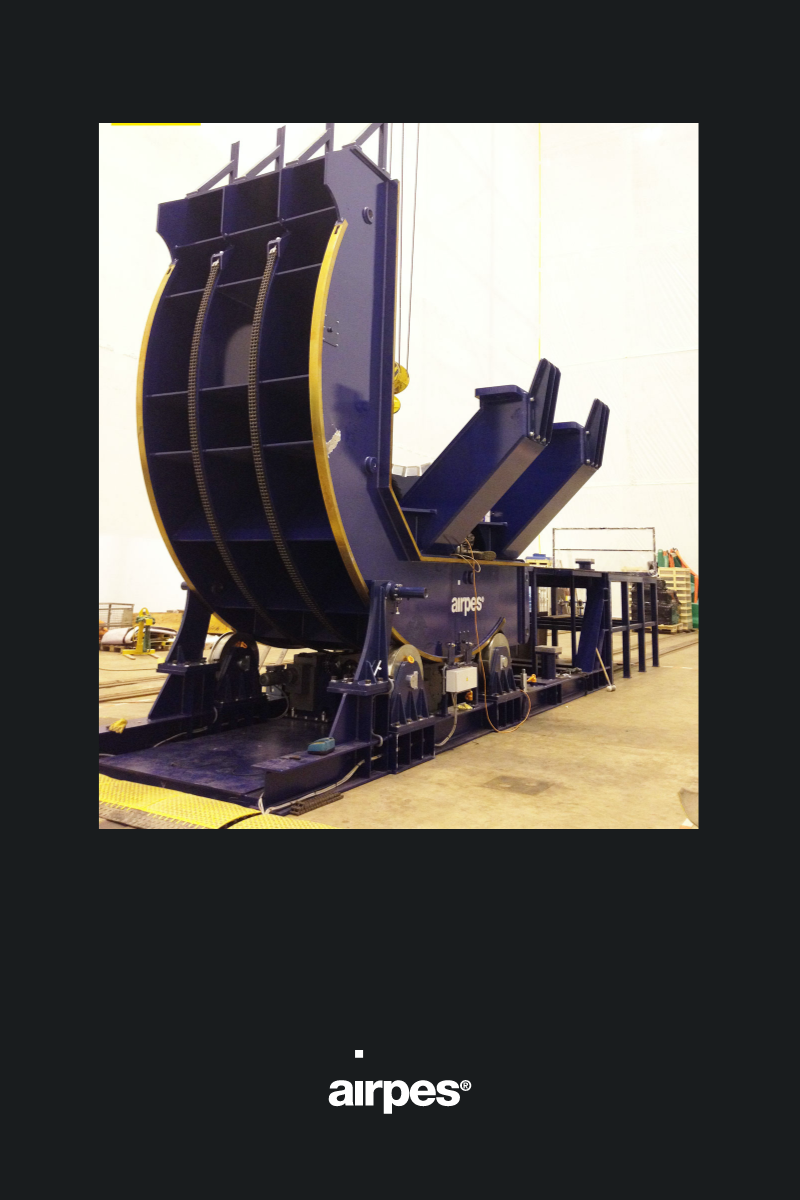

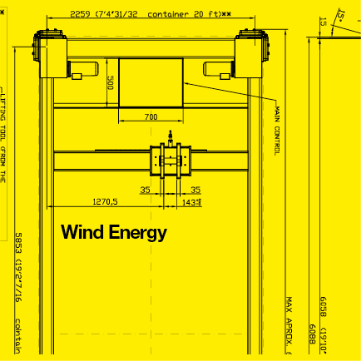

Lifting equipment for moving wind turbine blades for Vestas

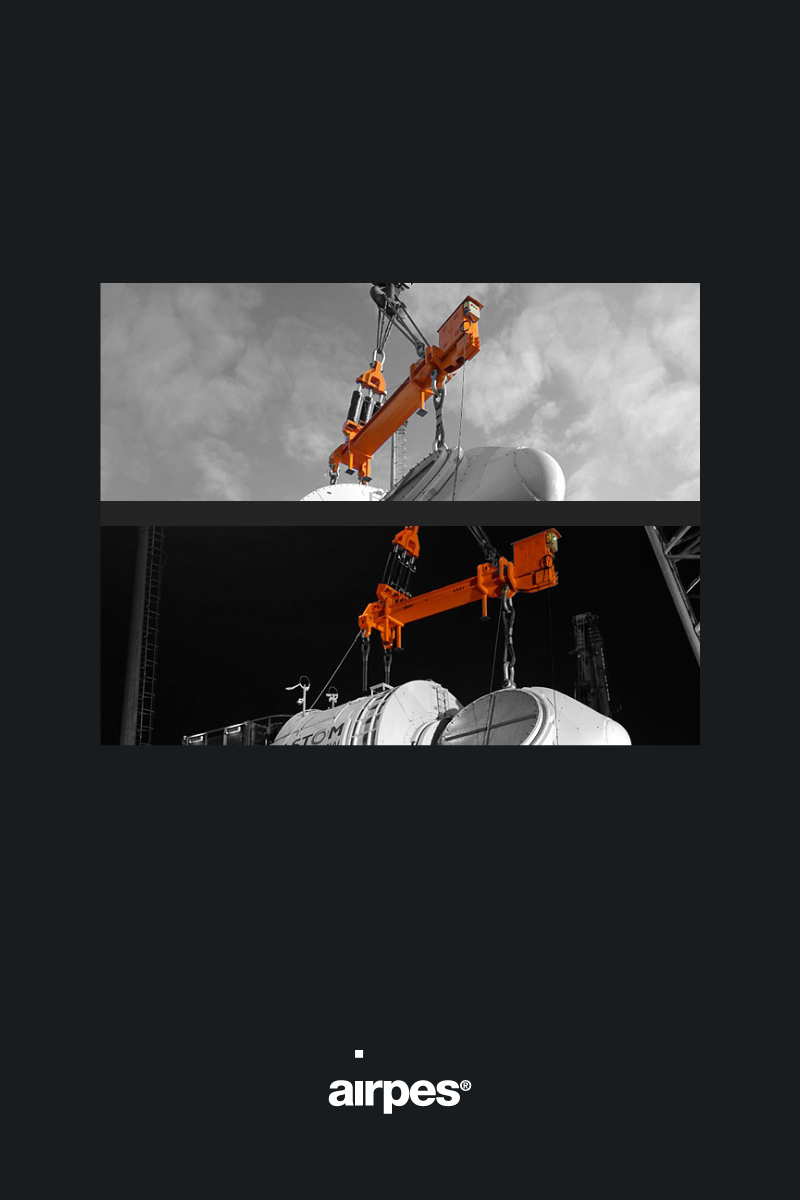

The company VESTAS works with wind turbine blades and was preparing various shipments. In order to improve the productivity and efficiency of those shipments, they required a renewed lifting equipment.

Initial situation description

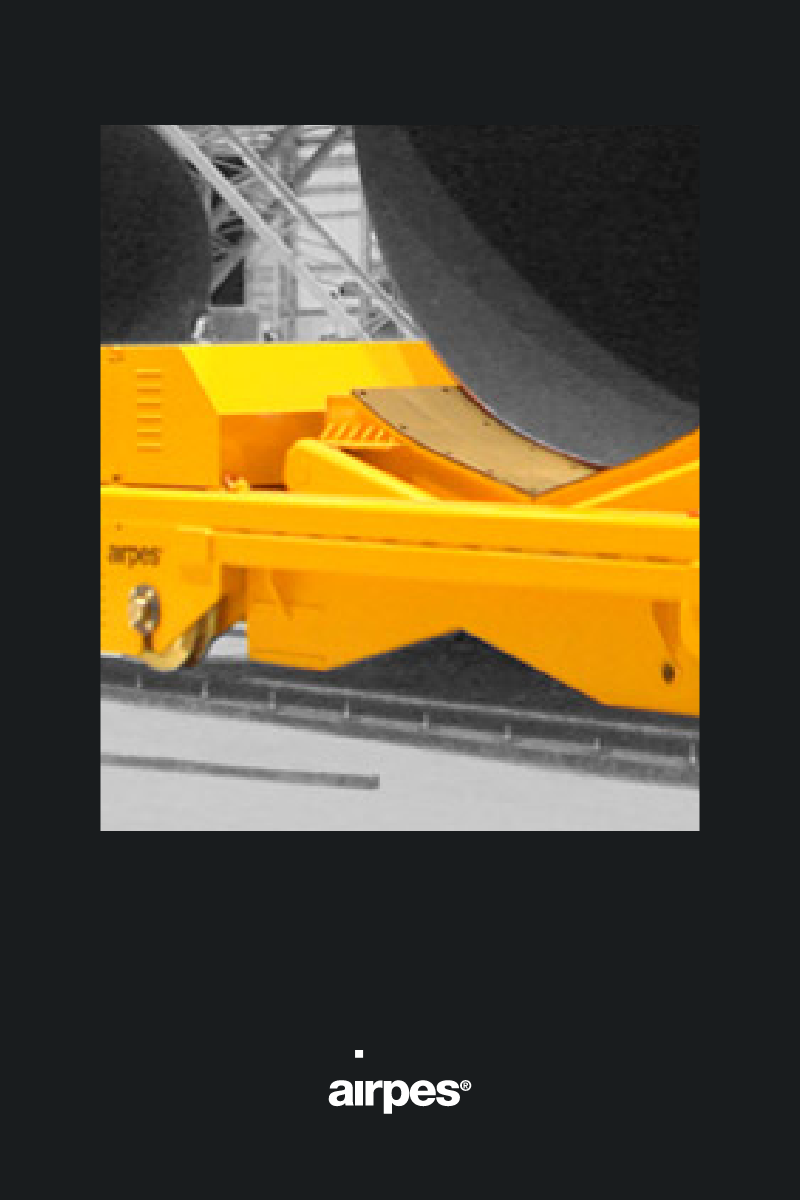

The customer has a reachstacker type forklift with 30 t capacity. The blades are produced in the plant, but their preparation is carried out outside this area outdoors. They were working with two automatic cranes and the main drawback is the rent cost.

Airpes is responsible for the design and construction of the lifting equipment and turning equipment for Vestas.

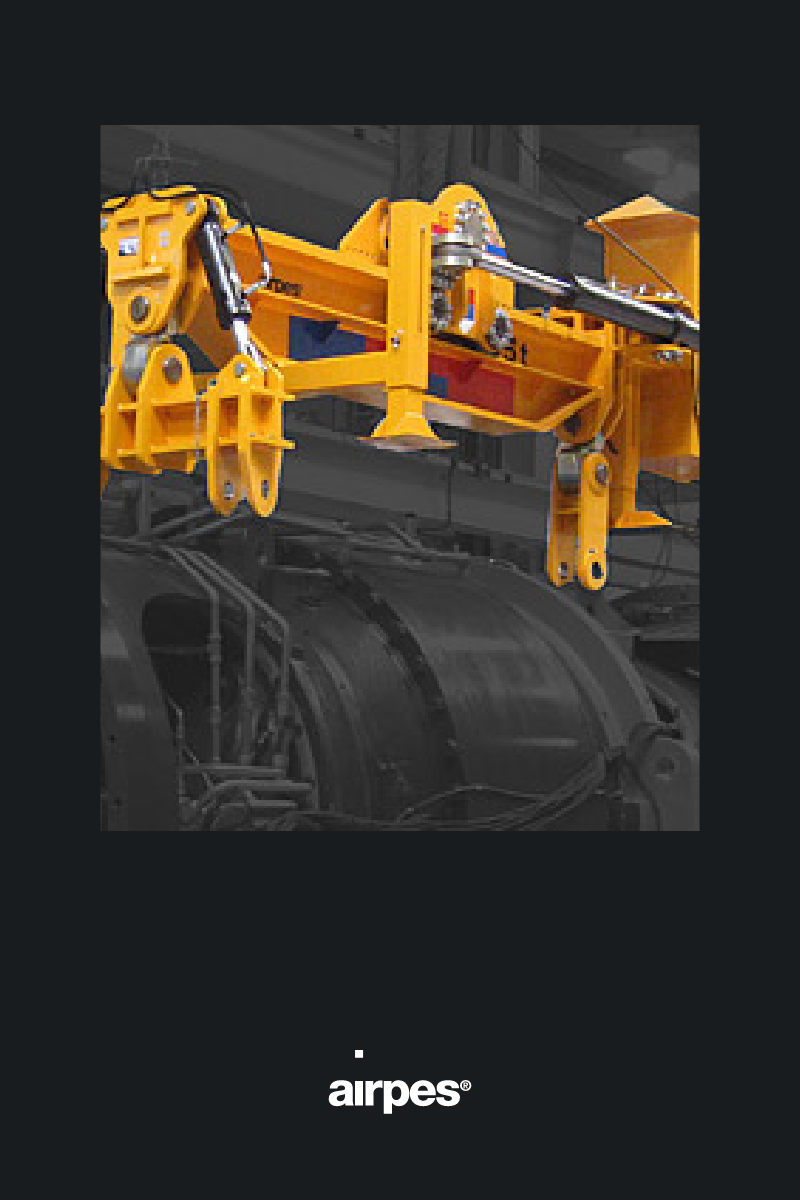

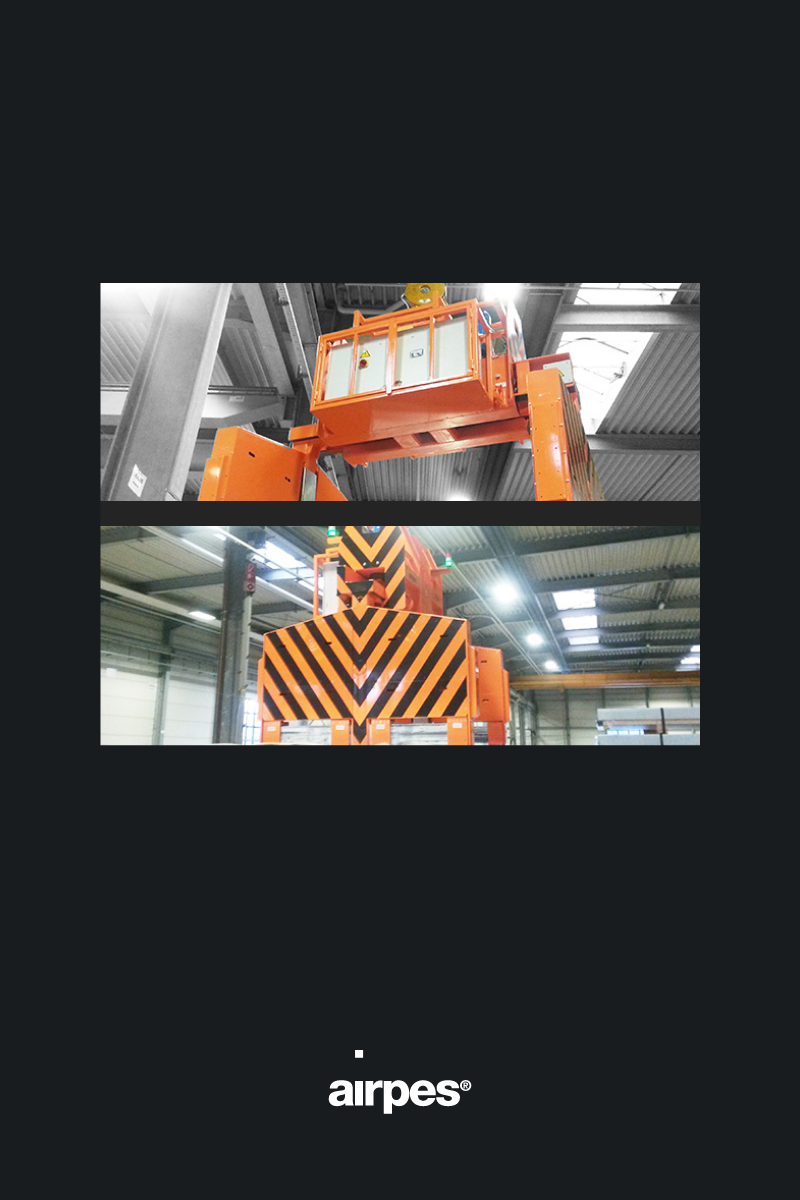

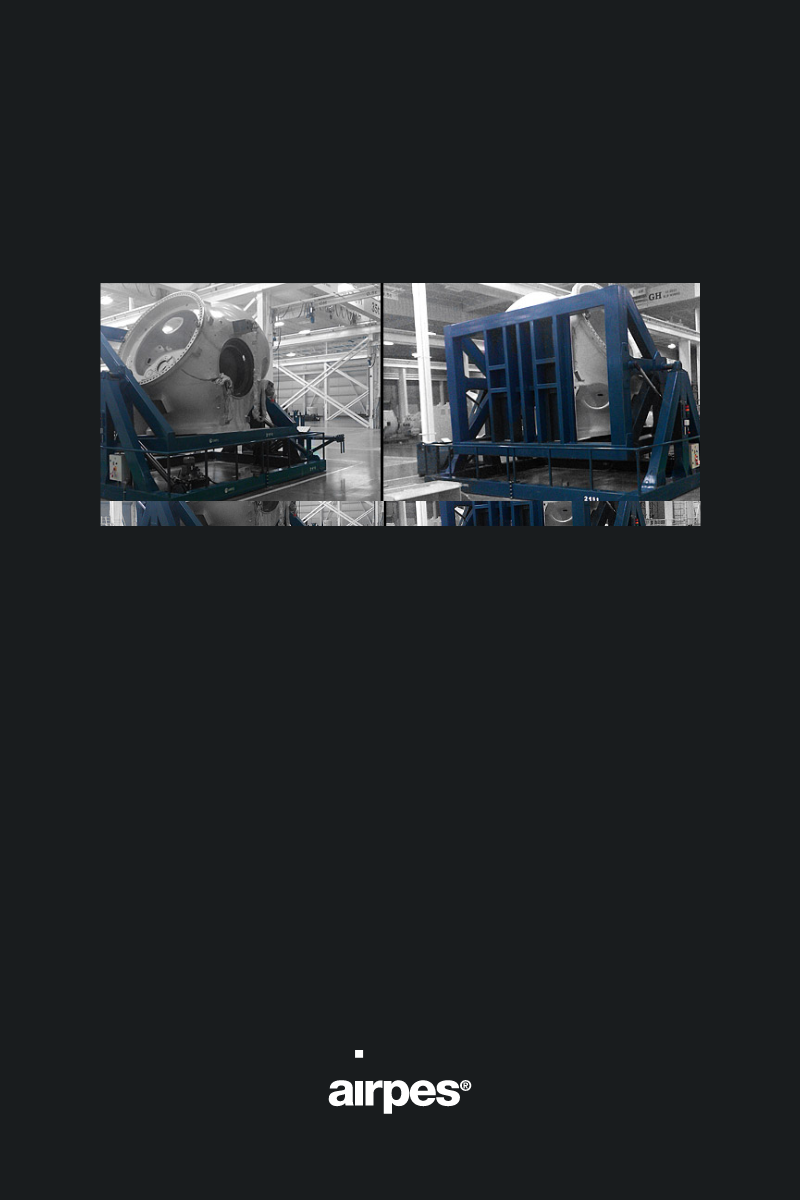

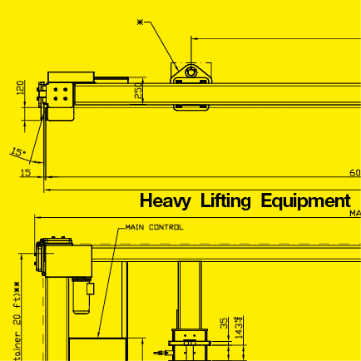

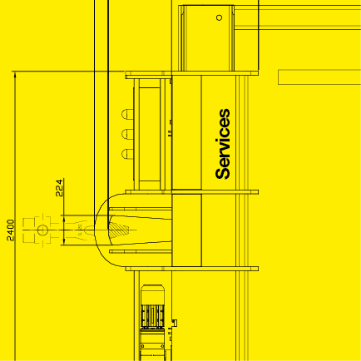

The proposal made by Airpes is a lattice type project. The lifting and turning actions are carried out by 4 adjustable winches installed aboard the lattice.

The lifting equipment’s control is electrohydraulic and is fully integrated to the reachstacker commands. The device joins the reachstacker by a twistlocks system.

FEATURES OF THE LIFTING EQUIPMENT

The lifting equipment has a touch screen installed in the cockpit to control all security elements:

- Angle

- Wind load information

- Signal video cameras

- And others

- The design and manufacture of this lifting equipment has been carried out correctly and the client Vestas is satisfied with the results, improving their productivity to move the wind turbines while preparing them for shipping.

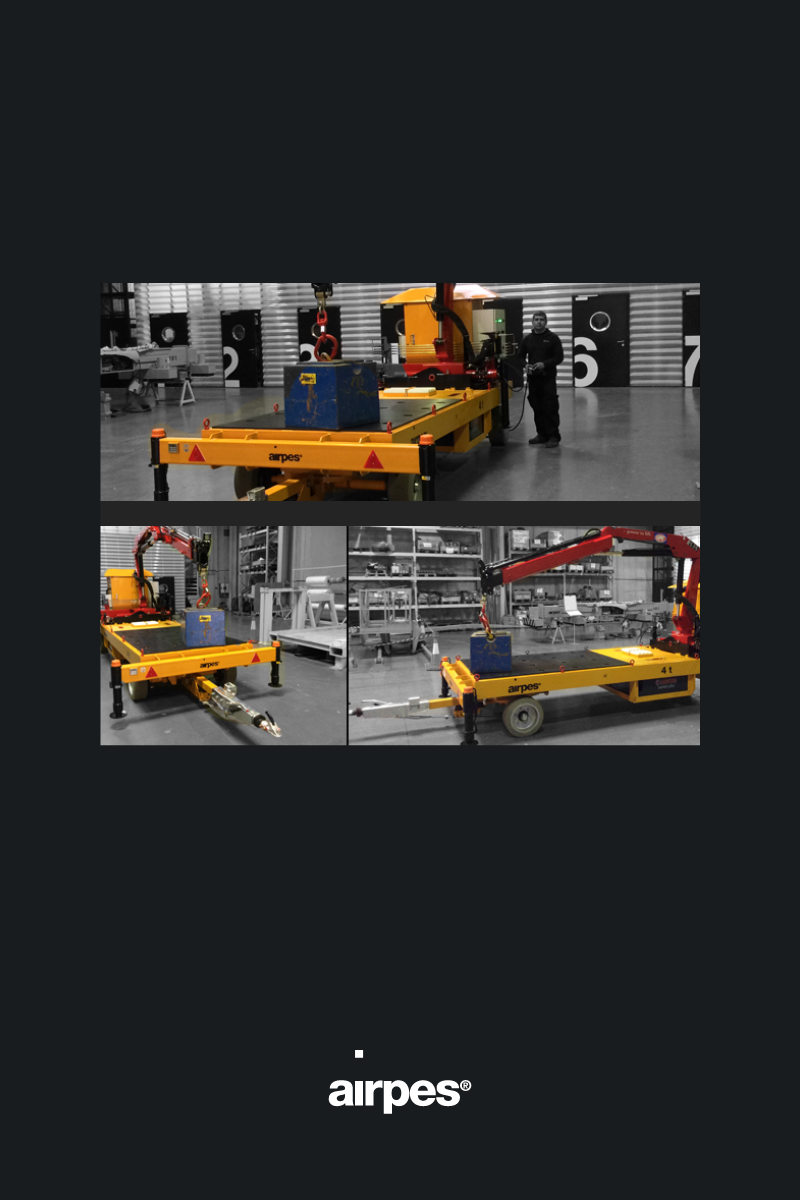

OUR on demand solutions

Airpes Solutions

LATEST POSTS ON THE BLOG

Discover our brand new developments, events, get posted of our activity.

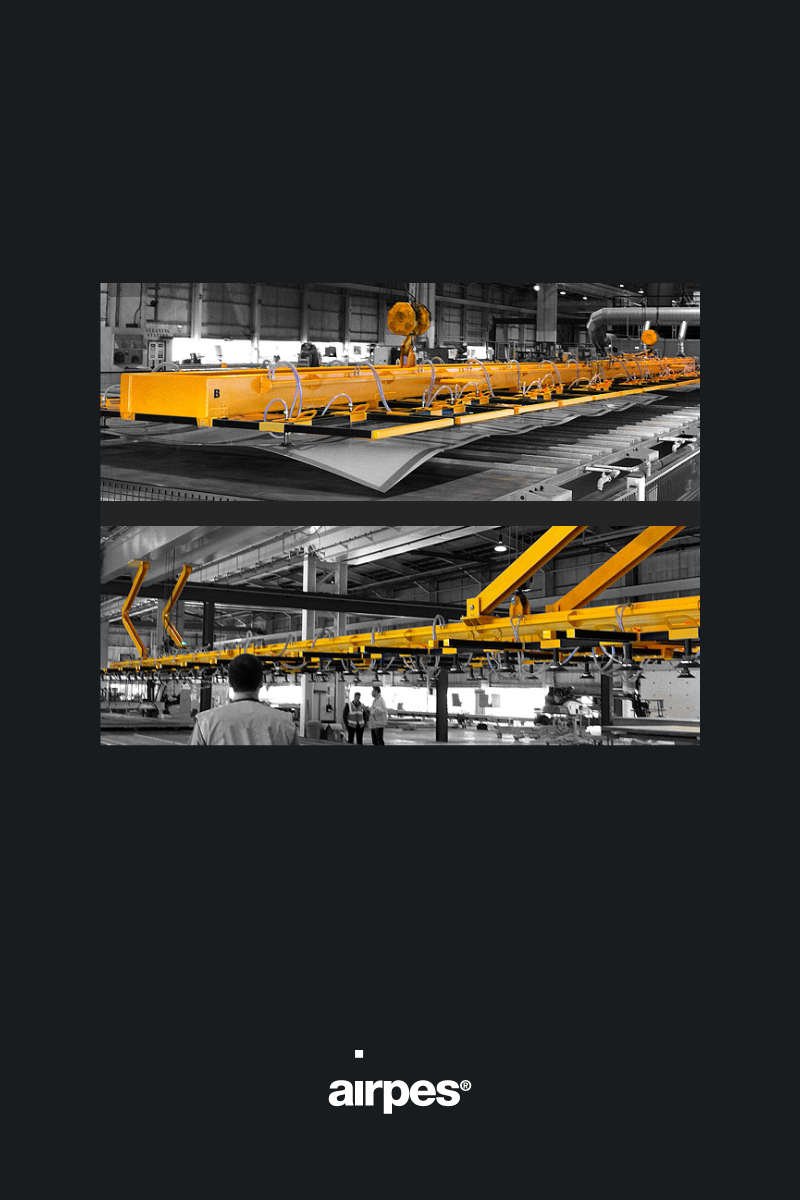

- What is a lifting electromagnet system and how does it work?Lifting electromagnet systems offer a safe, efficient, and cost-effective solution for handling steel plates, beams, and other ferrous...

- Why crane load block is an essential tool in lifting operationsLearn how crane load blocks improve lifting operations by optimizing weight distribution, reducing strain, and ensuring safety. Discover...

- Wind turbine blades: design, curiosities and moreHave you ever wondered how a wind turbine tower can support so much weight? Here all the details...

- Monorail Crane: pros, cons, and best uses explainedExplore the advantages and limitations of monorail cranes, and learn how to maximize their use for more efficient...