Safe Crane Operations: the importance of the lift director’s role

A good lift director naturally possesses leadership qualities and is someone that others trust to make knowledgeable decisions and to stick with them. Lift directors are dependable and reliable with the experience needed to guarantee safe lifting and rigging operations.

Continue reading to learn about the person who oversees lift operations.

OSHA Is Where It All Begins

Anyone who works with cranes is familiar with OSHA 1926.1432, which includes multiple-crane/derrick lifts. One job that is designated by these regulations is that of the lift director. The OSHA rule plainly states:

“The multiple-crane/derrick lift must be directed by a person who meets the criteria for both a competent person and a qualified person, or by a competent person who is assisted by one or more qualified persons (lift director). The lift director must review the plan in a meeting with all workers who will be involved with the operation.”

In the past, lift directors were commonly referred to as “lead persons” on a rigging crew. Although the OSHA doesn’t go into specific detail, the title designation allows them to perform corrective actions when looking over a lift plan.

Often, the lift director takes on more responsibility than the job’s crane operator and site supervisor and in some situations the lift director and site supervisor are the same person.

Assigning lift directors to your projects ultimately saves lives, in that it guarantees an experienced and qualified person is strategically supervising each lift and is authorized to make the changes needed once a problem arises.

OSHA reinforces the regulation that a lift director be a named person and fully accountable for their actions. If a severe accident occurs, the lift director runs the risk of having serious charges brought against them, so this is a role that should not be taken lightly.

What exactly does the lift director do?

As reported in The American Society of Mechanical Engineers protocol B30.5, the responsibilities of a lift director include:

- Confirming that the proper traffic controls are implemented.

- Guaranteeing that rigging is carried out by competent personnel.

- Stopping crane operations if warned of unsafe conditions.

- Ensuring the load is balanced and rigged properly.

- Making sure area preparations have been completed prior to crane operations.

- Carrying out precautions for special lifting operations like multiple crane lifts.

- Assigning signal people that meet the proper requirements.

- Permitting crane operations by power lines only once appropriate requirements are met.

- Guaranteeing workers comprehend their responsibilities and the associated hazards.

OSHA also requires that lift directors are qualified and competent— or competent and assisted by a qualified person — when operating multiple crane lifts.

It is essential that companies hire highly-trained, NCCCO-certified crane operators to carry out jobs safely. The National Commission for the Certification of Crane Operators is a nonprofit organization whose mission is to create sufficient performance standards for safe crane operation to help all segments of construction and general industry.

How Do You Become a Lift Director?

The first step towards becoming a lift director learning to create a series of lift plans based off of several scenarios. After this, you’ll need to take the (NCCCO) Lift Director Exams. You must be able to solve several problems, from risk assessment and hazard recognition to personnel placement and load travel path.

The quickest way to qualify may be through the Industrial Training International’s Lift Director & Critical Lift Planning Course. This 3 day program covers lifting operations, load handling equipment (LHE) placement, rigging capacities, site set-up, load charts, rigging decisions and other critical lift planning elements.

The critical lift part of the course is focused on the risk assessment process, crane operating areas, personnel assignments and competencies, compiling crane and rigging data, a safety checklist, a proposed sequence of events, contingency plans and rigging methods.

Crane Institute of America offers another Lift Director training course. They are located in Florida but might have a training partner near you.

If you would like to learn more about the lift director’s responsibilities, read ASME B30.5 (Locomotive and Mobile Cranes), ASME P30.1 (Lift Planning) and 29CFR1926.1400 (OSHA).

Some of our lifting systems

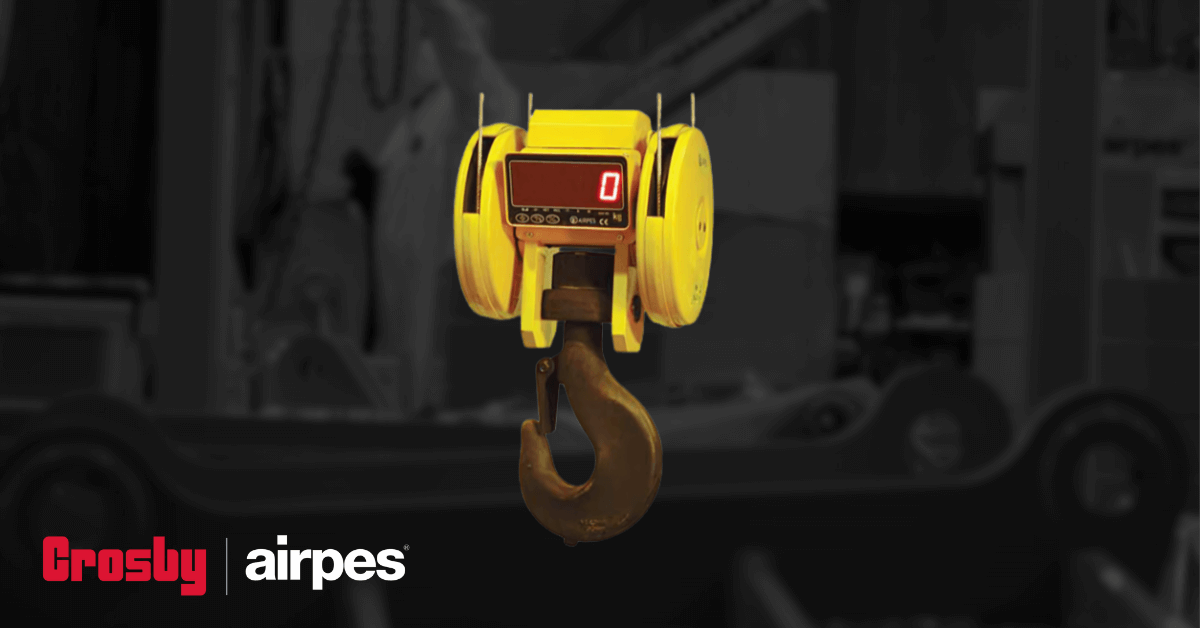

Crosby Airpes is specialized in lifting equipment at all levels, from simple cranes to lifting solutions for the wind industry.

Some of our most renowned systems are the following:

-

LIFTING ELECTRO MAGNET

We have the most interesting products in the industrial electromagnet field because we are in charge of the whole lifting electromagnet design, but…LIFTING ELECTRO MAGNETSeptember 22, 2020

-

LIFTING BEAM

Airpes offers many types of lifting beam designs, some of them are fixed beams, H beams, the moveable center of…LIFTING BEAMSeptember 22, 2020

-

TRANSFER CART

At Airpes we design our own high-tech transfer carts for any kind of industrial facilities. We can manufacture every transfer…TRANSFER CARTSeptember 22, 2020

We are the lifting equipment supplier you’re looking for

Crosby Airpes has more than eighteen years of experience designing, manufacturing and delivering the best lifting equipment. With our solutions, there won’t be load you can’t move.