If your business deals with handling steel plates and bars, metal beams, or heavy-duty industrial materials, then you know how crucial it is to have the right lifting equipment.

Traditional lifting methods, such as hooks, slings, or clamps, can be inefficient and pose significant safety risks. That’s where lifting electromagnet systems come in—offering a secure, fast, and reliable way to move ferrous materials in various industries.

But what exactly is a lifting electromagnet system, how does it work, and how can it improve your operations?

What is a lifting electromagnet systems?

An electromagnet is a lifting device that creates a magnetic field when an electric current is passed through it. This lifting electromagnet attracts ferrous materials such as steel plates, beams, and scrap metal, allowing industries to lift and move heavy loads safely and efficiently.

Unlike permanent magnets, electro magnets can be activated and deactivated with precision, allowing complete control over the lifting and release of materials. This makes them highly adaptable to industrial applications where efficiency and safety are critical.

How does a lifting electromagnet work?

The operating principle of a lifting electromagnet is based on electromagnetism. But how is electromagnetism used in industry and technology to optimize lifting processes?

Here’s how it works:

- Electric current flows through a coil, creating a powerful magnetic field.

- This field attracts and holds ferrous materials such as steel plates and beams.

- When power is cut off, the magnetic field collapses, releasing the load.

- Advanced magnetic lifting devices offer adjustable power settings for different materials.

This simple yet effective mechanism provides precision, control, and high lifting capacity in industrial environments.

You may be interested in: 10 safety precautions when using lifting equipment

Types of lifting electromagnets

Choosing the right industrial electromagnet depends on your specific lifting needs. The main types include:

Circular lifting electromagnets

Ideal for lifting round or irregularly shaped metal objects. They are commonly used in scrap handling and recycling plants.

Rectangular lifting electromagnets

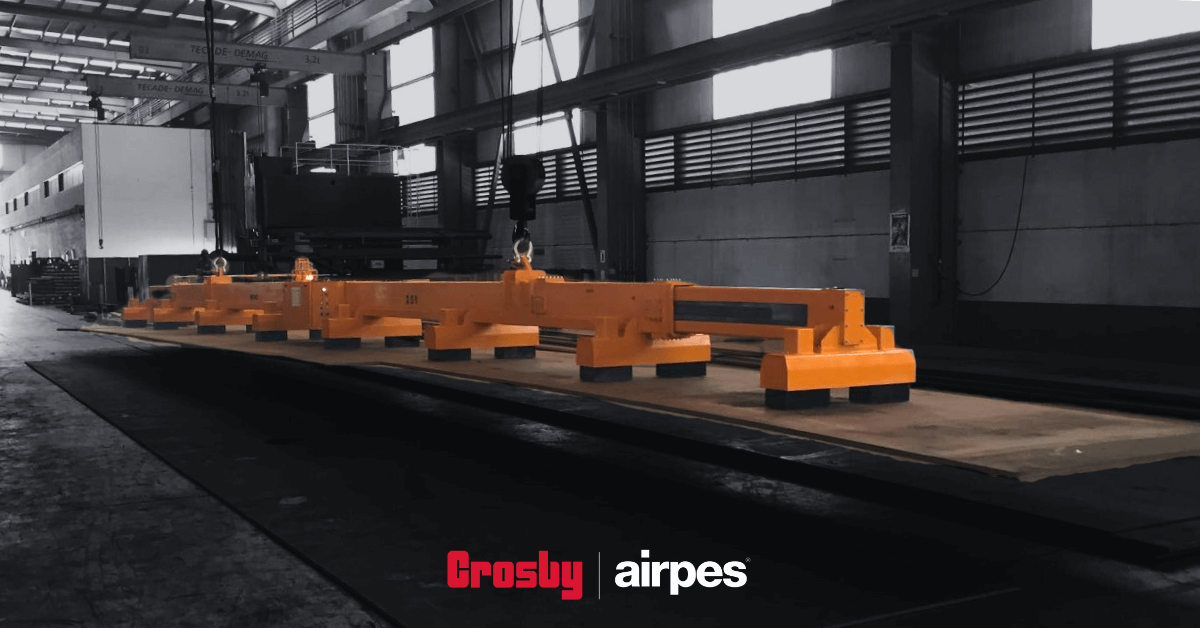

Designed for handling steel plates and bars, sheet metal and long beams. Used in shipbuilding, metal fabrication and steel mills.

Battery powered lifting electromagnets

Offer flexibility with battery-powered wireless operation. Suitable for environments where direct power supplies are not available.

Electro permanent magnets

Maintain a magnetic hold even during power loss, preventing accidental drops.

You may be interested in: 5 safety tips for electromagnets’ uses

Benefits of using industrial electromagnet

The benefits of integrating an electromagnetic lifting system into industrial processes are numerous:

- More efficient lifting times, reduced risks and faster material handling.

- Increased workplace safety, minimizing manpower requirements and reducing workplace.

- Operating costs are reduced by reducing labour costs and equipment wear and tear.

- Precise load control is achieved as the adjustable lifting power of the electromagnet ensures safe handling of a wide range of materials.

- Its versatility means it can be used in all industries, including steel fabrication, shipbuilding and heavy lifting.

How to choose the right lifting electromagnet

Choosing the right type of electromagnet depends on several factors:

- Material type: are you lifting steel plates, beams, or irregular scrap metal?

- Load weight: identify the lifting capacity of the electromagnet required for your operation.

- Work environment: indoor, outdoor, high-temperature, or hazardous environments require special magnetic lifting devices.

- Power supply: AC, DC, or battery powered electromagnets for different applications.

- Automation and integration: can the electromagnet be integrated with your existing crane or hoist system?

Additional features to enhance a lifting electromagnet system

Additional features to enhance a lifting electromagnet system

Optional features can be added to every lifting magnet installation to make the most of your material handling magnet. For example:

- Telescopic opening/closing

- Special suspensions

- Fixed welded hooks to increase system’s versatility

- Protection pads

- Loose cable control

- Collision control

- Stock in/out control on every lift

- Radio control or device information

- Battery powered (power failure safety system)

- Integrated rotation

Which lifting electromagnet system is right for your industry?

Implementing lifting electromagnet systems in industrial operations improves productivity, reduces costs, and enhances workplace safety. At Crosby Airpes, we specialize in electromagnet design and provide custom lifting electromagnet solutions for various industries.

Our lifting electromagnets offer:

- Customizable designs tailored to your specific lifting needs.

- Energy-efficient technology for reduced power consumption.

- Enhanced safety features, including remote control and automatic failsafe mechanisms.

- Seamless integration with cranes, hoists, and material handling equipment.

Is your company ready to optimize its lifting processes? Contact Crosby Airpes today for expert advice and custom electro magnet solutions.

Additional features to enhance a lifting electromagnet system

Additional features to enhance a lifting electromagnet system