In the world of heavy lifting and industrial operations, precision and safety are paramount. Among the critical components ensuring efficient and secure load handling is the crane load block. This indispensable tool is vital in construction, metallurgy, and wind energy, where lifting heavy loads is a daily requirement.

But what exactly is a crane load block?

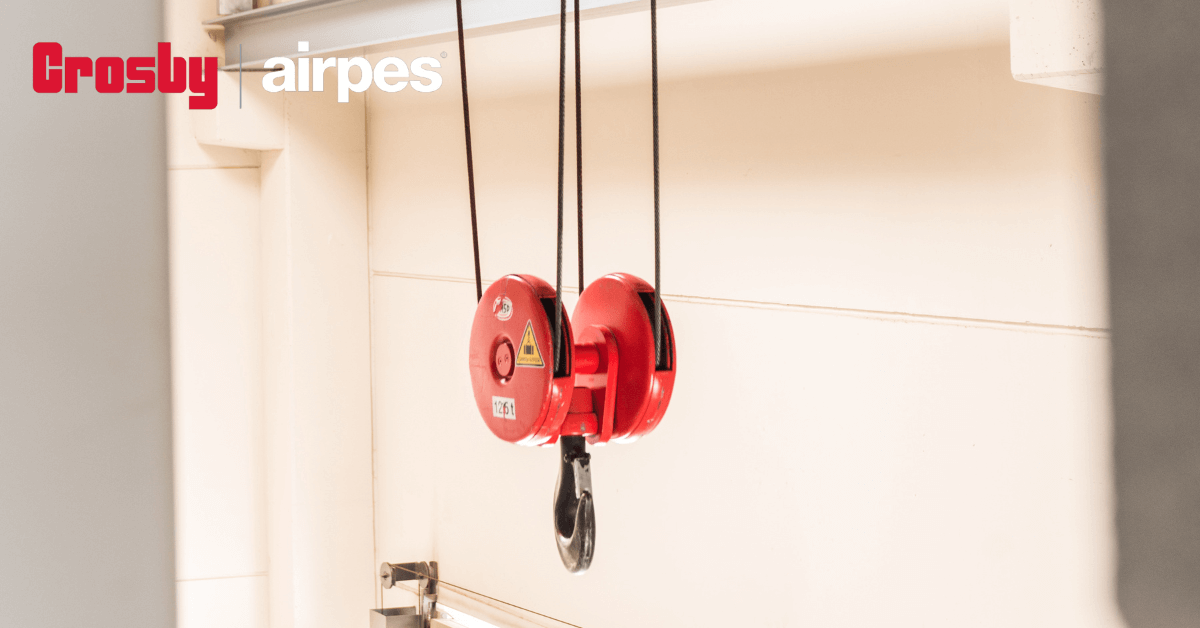

A crane load block is a critical component of a crane’s lifting system. It is the lower assembly attached to the crane’s hook and is responsible for safely lifting and holding loads.

That is to say, a crane load block is a robust assembly used to hoist and manage heavy loads safely. It connects to the crane’s cable system and is responsible for distributing weight effectively.

What are the components of a crane load block?

Key Components:

- Hook: is the load securing point, designed to handle a range of loads while maintaining high safety margins.

- Sheaves or pulleys: help distribute the weight, reduce mechanical stress on the cable and optimize energy efficiency.

- Load pin: secures components and transfers the load to the lifting system.

- Shell or frame: protects the inside parts and improves durability. It is often made from strong alloys for industrial strength.

These components work together to optimize the crane’s functionality, ensuring the safe handling of heavy materials under varying conditions.

Features that improve lifting operations

Crane load blocks make lifting heavy loads easier. They help distribute weight better and reduce the effort needed. They are essential for:

- Protecting the crane rope from excessive wear and tear, extending its service life.

- Balancing loads to avoid tipping or swinging, key factor during high-altitude lifting or in windy conditions.

- Increase crane productivity by lifting heavier loads safely and efficiently, reducing downtime and operating costs.

In shipbuilding, crane load blocks help safely move large parts like ship hulls. In the energy sector, they assist with turbine installation needs.

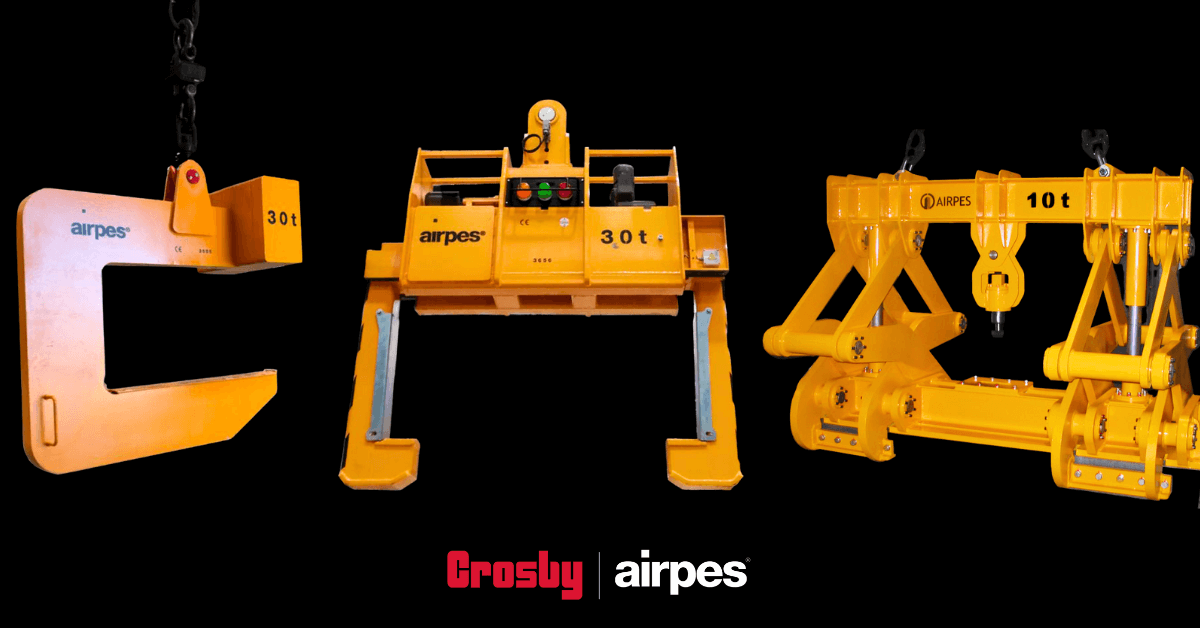

Types of crane load blocks

Different types of crane load blocks are tailored to meet specific operational needs.

- Rotating crane load blocks: designed for operations requiring load rotation, ideal for aligning components during assembly.

- Motorized rotating crane hooks: improve automation and control. They are important for precise tasks, like placing machinery parts in tight spaces.

- Standard load blocks: reliable and cost-effective, suitable for general lifting applications in warehouses or small-scale projects.

Industry applications of crane load blocks

Industry applications of crane load blocks

- Construction

Crane load blocks are pivotal in hoisting materials like steel beams, concrete sections, and large equipment for skyscraper and bridge construction. Their ability to ensure precise placement and load balance significantly reduces the risk of accidents in high-altitude operations.

- Wind Energy

These blocks are indispensable during the installation and maintenance of wind turbines. They handle large rotor blades and heavy nacelles, ensuring safe and efficient handling in tough places, like remote and windy areas.

- Mining

In mining operations, crane load blocks help move large machines and raw materials like ore and minerals. Their precision and durability ensure smooth operations even in harsh, abrasive conditions, reducing downtime and increasing productivity.

How to select the right load block

The key factors to consider when selecting the right load block are critical for safe working spaces, as workers, and being efficient at an operational level.

- Load capacity: check that the block can handle the maximum weight of its operations, taking into account safety margins.

- Compatibility: ensure the block is perfectly integrated with your crane’s specifications and lifting mechanisms.

- Durability: the materials must be high-quality, such as reinforced steel or composite alloys, designed exclusively to withstand harsh environments and according to the needs of the activity.

- Compliance: ensure the block complies with international safety and performance standards, such as ISO.

Working with experienced manufacturers or suppliers ensures optimum performance and long-term reliability.

Maintenance and safety best practices

Proper maintenance helps crane load blocks last longer and work reliably. It also extends the life of the equipment. This protects against failures that could lead to accidents. Following the practices below is essential.

- Perform regular inspections on the block for signs of wear, deformation or corrosion, paying close attention to the pulleys and hook.

- Keep the smooth running of lubricated pulleys and bearings to minimize friction and wear.

- Perform periodic load tests under maximum operating capacity to ensure the structural integrity of the block.

- Training of operators is essential, ensuring that they can recognize warning signs and follow the correct usage protocols.

- Preventive maintenance not only extends the life of equipment but also protects against operational failures that could lead to accidents

Innovations in crane loading blocks

Innovations in crane loading blocks

Smart monitoring systems have built-in sensors. They give real-time data on load weight and stress. This helps improve decision-making and prevent overload.

Lightweight, strong materials like carbon fiber composites are replacing traditional steel. This change helps reduce weight while keeping durability.

Solutions to improve your lifting operations

In many industrial operations, inefficiencies begin with incorrect load distribution, frequent cable wear, or downtime caused by inadequate lifting equipment. These challenges not only increase operational costs but also compromise safety and productivity.

Crane load blocks help solve these problems by optimizing weight distribution, enhancing stability, and minimizing mechanical strain. If your industry struggles with heavy loads or lifting operations, Crosby Airpes has solutions designed to improve efficiency, safety, and reliability.

Industry applications of crane load blocks

Industry applications of crane load blocks Innovations in crane loading blocks

Innovations in crane loading blocks